External turning tool: an efficient tool in the field of mechanical processing

As one of the indispensable tools in machining, external turning tools have always played a vital role. With the continuous development of the manufacturing industry and the advancement of technology, the performance and application range of external turning tools are also expanding. This article will introduce in detail the latest development of external turning tools and their applications in various industries.

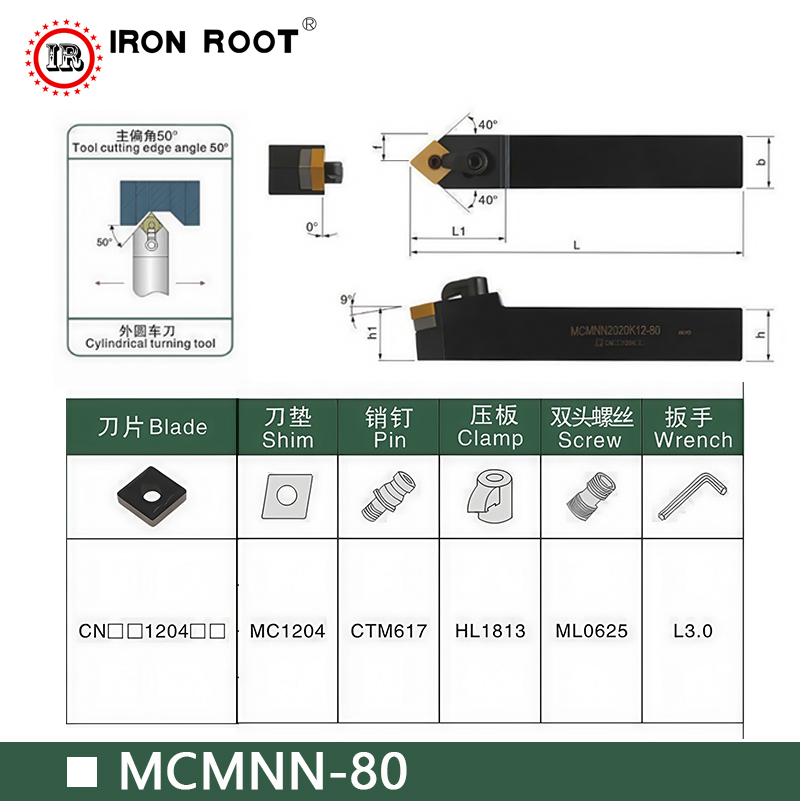

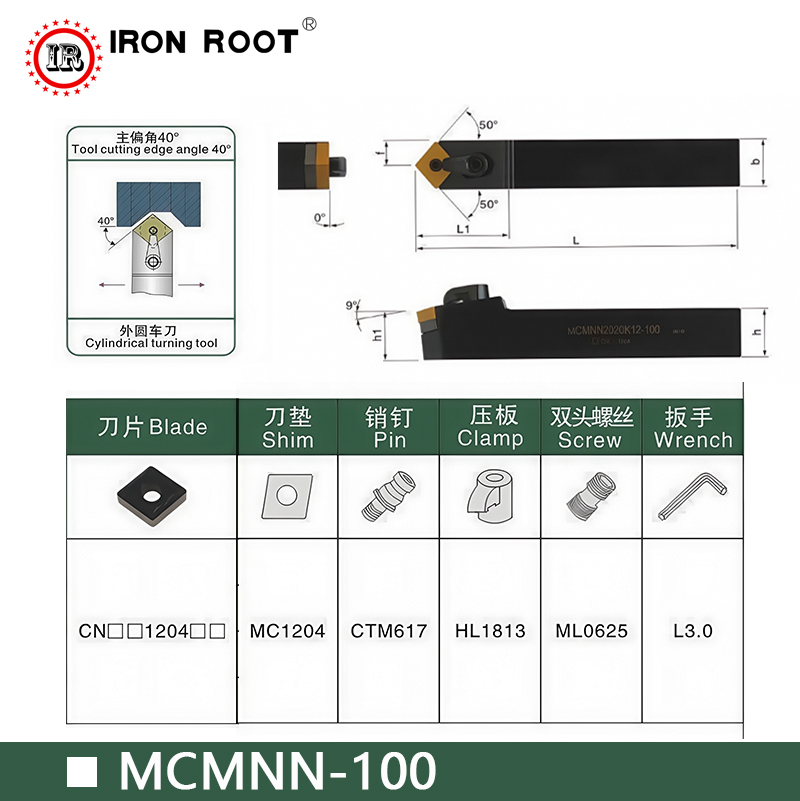

External turning tools are tools used in lathe machining, mainly used for machining external circles, end faces and internal holes. Their unique design and efficient cutting performance make them very popular in the field of mechanical machining. In recent years, with the advancement of material science and manufacturing technology, the material and coating technology of external turning tools have also been significantly improved. For example, carbide external turning tools have become the first choice for many high-precision machining tasks due to their high hardness, high wear resistance and good thermal stability.

In terms of the application of external turning tools, different types of turning tools are suitable for different processing needs. For example, 95-degree external turning tools can perform a wider range of processing operations on different workpieces due to their large angle range, and have high versatility. In addition, indexable turning inserts such as VNMG 12T304-NF IC907 and DCGT 11T304-F2M IC908 are widely used in semi-finishing and finishing due to their low cutting force and good chip breaking performance.

In the field of medical device manufacturing, external turning tools are also widely used. For example, Iscar's high-efficiency medical device processing tools can meet the requirements of repeated positioning accuracy and rigidity, and are suitable for the processing of small parts. In addition, in the field of automobile manufacturing, external turning tools also play an important role. Zhuzhou Diamond's external turning tool products are complete, and can provide customers with various standard and non-standard physical coatings, chemical coatings, metal ceramics and superhard materials. High-precision turning tools.

With the continuous development of the manufacturing industry, the market demand for external turning tools is also growing. Especially in the fields of precision machinery, aerospace, etc., the application prospects of external turning tools are broad. For example, the 105° wedge-type external cylindrical profiling turning tool, as a key tool for efficient and precise processing, has significant advantages in improving production efficiency, reducing processing costs, and improving product quality.

In short, external cylindrical turning tools play an indispensable role in modern manufacturing. Its efficient cutting performance and wide range of applications make it an efficient tool in the field of mechanical processing. In the future, with the continuous advancement of technology, the performance and application range of external cylindrical turning tools will be further expanded, providing stronger support for the development of the manufacturing industry.