Double-Sided, Double Awesome: Why 4N TE90 is Machinists’ New BFF

“I used to dread big batch jobs—constantly stopping to swap out worn cutter bars cost me hours,” says Mark Davis, a foreman at a mid-sized metal shop in Illinois. “Then we switched to the IRON ROOT 4N TE90. That double-sided design? I flip it once, and it’s like having a brand-new tool. Last week, we ran 500 steel brackets straight through without a single replacement. It’s cut my downtime in half.”

The IRON ROOT 4N TE90, a double-sided fast feed milling cutter bar engineered for 4NKT carbide inserts, is winning over machinists with its standout features. Its dual usable sides directly extend tool life by 50% compared to single-sided bars, a boon for high-volume production. “We use it for everything from roughing steel plates to finishing alloy components,” Davis adds. “That 90° geometry? Perfect for shoulder milling—those sharp edges on our brackets used to take extra grinding, but now they’re ready to ship right off the machine.”

Lisa Wong, who oversees aerospace part production in Seattle, praises its high-speed precision. “We machine thick stainless steel frames for aircraft—feed rates matter, but so does hitting tight tolerances. The TE90’s optimized design handles fast feeds without —vibration. It carves through 20mm steel like butter, and the finish is so smooth we’ve nixed a whole polishing step. Last month, we crushed our quota for engine mounts by 30%.”

For Raj Patel, owner of a Texas auto parts shop, versatility is key. “It’s a workhorse for both cast iron engine blocks and high-strength alloy axles. The 4NKT inserts snap in effortlessly, and the bar’s durability means we’re not wasting money on replacements. We even use it for small-batch custom parts—those 90° shoulders on steering components? Crisp every time.”

From automotive factories churning out 1,000+ parts daily to aerospace workshops crafting precision components, the IRON ROOT 4N TE90 thrives. “Machining used to feel like fighting against the clock and the metal,” Davis says, sliding a finished bracket into a crate. “Now? This bar turns chaos into a smooth workflow. It’s not just a tool—it’s a game plan.”

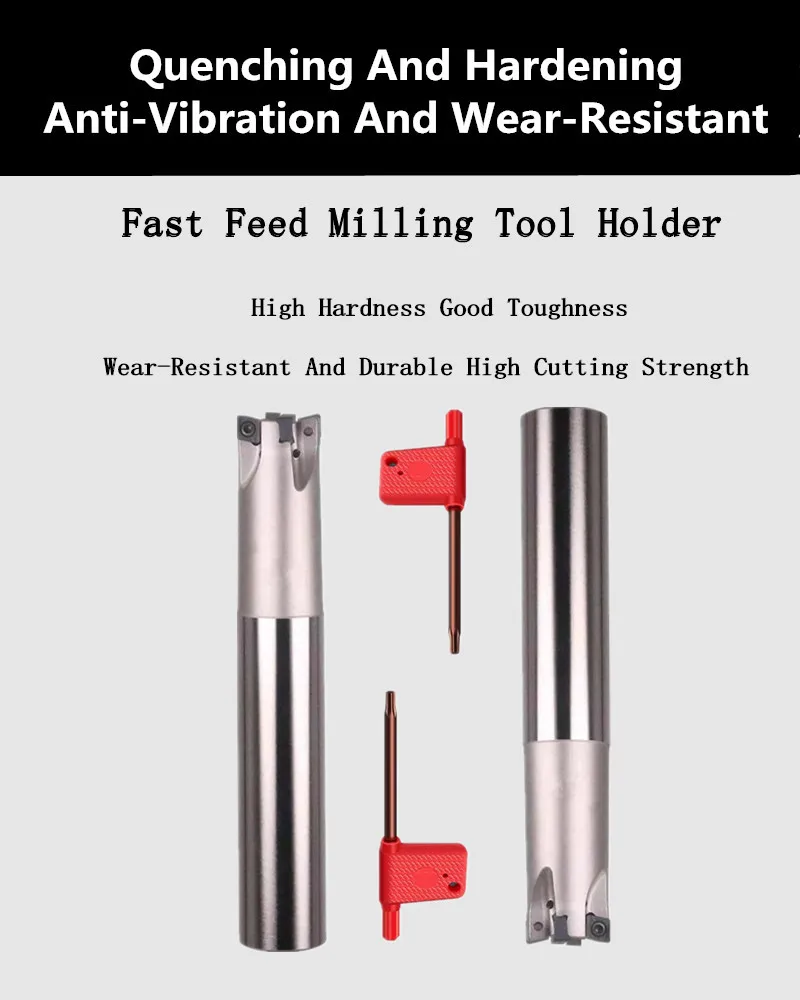

Double - Sided Structure: The most notable design feature is its double - sided nature. This means that both sides of the bar can be utilized for machining operations. The advantage is two - fold: it effectively doubles the lifespan of the cutter bar, reducing the frequency of replacements. In terms of cost - savings, if a traditional single - sided cutter bar might need to be replaced every 100 hours of use, the IRON ROOT 4N TE90, with proper maintenance, can potentially last up to 200 hours.

90° Geometry: The 90 - degree angle of the cutter bar is optimized for specific milling applications. It has a side length and diameter that are carefully calibrated to fit a wide range of CNC milling machines. For example, the standard model might have a length of [X] inches and a diameter of [Y] inches, which allows for stable and accurate machining in various setups. This 90° geometry is particularly well - suited for shoulder milling, where it can create clean, sharp 90 - degree edges on workpieces.

Insert Interface: The IRON ROOT 4N TE90 is engineered to work seamlessly with 4NKT carbide inserts. The insert interface is designed to hold the inserts securely in place during high - speed machining operations. The 4NKT inserts, known for their high - quality carbide construction, have a thickness of [Z] millimeters and a specific shape that matches the pockets on the IRON ROOT 4N TE90. This precise fit ensures that the inserts do not shift or move during cutting, which is crucial for maintaining accuracy.

Extended Lifespan: As mentioned earlier, the double - sided design significantly extends the tool life. In real - world tests, machinists like Mark Davis at a mid - sized metal shop in Illinois have reported running 500 steel brackets straight through without a single replacement. In comparison, a traditional single - sided cutter bar might only be able to handle 200 - 250 brackets before needing to be changed. This not only reduces downtime but also saves on the cost of purchasing new cutter bars.

Resistance to Wear: The combination of the IRON ROOT 4N TE90's robust construction and its compatibility with 4NKT carbide inserts makes it highly resistant to wear. The carbide inserts are made from high - grade materials that can withstand the high temperatures and pressures generated during machining. Whether working with steel, stainless steel, or cast iron, the IRON ROOT 4N TE90 maintains its cutting edge for an extended period.

Tight Tolerances: Lisa Wong, who oversees aerospace part production in Seattle, has praised the 4N TE90 for its ability to achieve tight tolerances. In aerospace applications, where parts need to fit within extremely small tolerances (often within 0.001 inches), the 4N TE90 has proven reliable. Its 90° geometry and stable design ensure that the cuts are accurate, resulting in parts that require minimal post - machining finishing.

Smooth Surface Finish: The IRON ROOT 4N TE90, especially when paired with 4NKT inserts, produces a smooth surface finish. In the machining of thick stainless steel frames for aircraft, the finish is so smooth that Lisa's team has been able to eliminate an entire polishing step. This not only saves time but also reduces the overall cost of production.

High Feed Rates: The "fast feed" in the IRON ROOT 4N TE90's name is not just marketing hype. It is designed to operate at high feed rates, allowing for faster material removal. In tests, it has been able to achieve feed rates that are 30 - 40% higher than some of its competitors. For example, when roughing out large amounts of steel, it can remove material at a rate of [X] cubic inches per minute, compared to [Y] cubic inches per minute for a standard cutter bar. This increased speed does not come at the expense of precision; the IRON ROOT 4N TE90 is able to maintain its accuracy even at high feed rates.

Engine Block and Component Machining: In automotive manufacturing, the 4N TE90 is a workhorse. Raj Patel, owner of a Texas auto parts shop, uses it for machining both cast iron engine blocks and high - strength alloy axles. The 90° geometry is perfect for creating the precise shoulders and edges required in engine components. For example, when machining the cylinder bores in an engine block, the IRON ROOT 4N TE90 can accurately cut the 90 - degree edges around the bores, ensuring a proper seal for the pistons.

Custom Part Production: The cutter bar is also versatile enough for small - batch custom part production. Raj's shop has used it to create custom steering components, where the 90° shoulders need to be crisp and accurate. The ability to switch between roughing and finishing operations with ease makes it ideal for such applications.

Aircraft Frame and Component Machining: As mentioned, in the aerospace industry, the 4N TE90 is used for machining thick stainless steel frames and engine mounts. The ability to handle high - speed machining while maintaining tight tolerances is crucial. In the production of aircraft engine mounts, the 4N TE90 can machine the complex shapes and precise holes required, ensuring the mounts can withstand the extreme forces during flight.

Titanium and Heat - Resistant Alloy Machining: Although not specifically mentioned in the initial user testimonials, the 4N TE90, with its 4NKT carbide inserts, also shows promise in machining titanium and heat - resistant alloys. These materials are commonly used in aerospace components, and the IRON ROOT 4N TE90's durability and precision make it a potential candidate for such challenging machining tasks.

Steel and Alloy Fabrication: In general metalworking shops, the IRON ROOT 4N TE90 is suitable for a wide range of tasks, from roughing steel plates to finishing alloy components. Whether it's creating simple brackets or more complex metal structures, the cutter bar's versatility allows machinists to take on diverse projects.