MGGN Carbide Grooving Inserts for Aluminum

1. MGGN Carbide Grooving Inserts for Aluminum are available in a variety of groove types to suit different processing requirements.

2. Grooving inserts for aluminum make cutting smoother and less likely to stick to the tool.

3. Excellent quality and sufficient stock.

About the product

1. Grooving inserts for aluminum are made of high-quality carbide, which has excellent durability and wear resistance, ensuring long-lasting performance.

2. The cutting edge and optimized geometry of Carbide inserts enable smooth and accurate cutting.

3. The efficient heat dissipation performance of MGGN aluminum grooving inserts protects the tool and material from thermal damage, extending tool life and workpiece integrity.

Specifications

Brand | |

Model | MGGN |

Workpiece | Aluminum/Copper/Zinc |

Type | Grooving inserts for aluminum |

Material | Cemented Carbide |

Quantity | 10pcs/box |

Package | Plastic box |

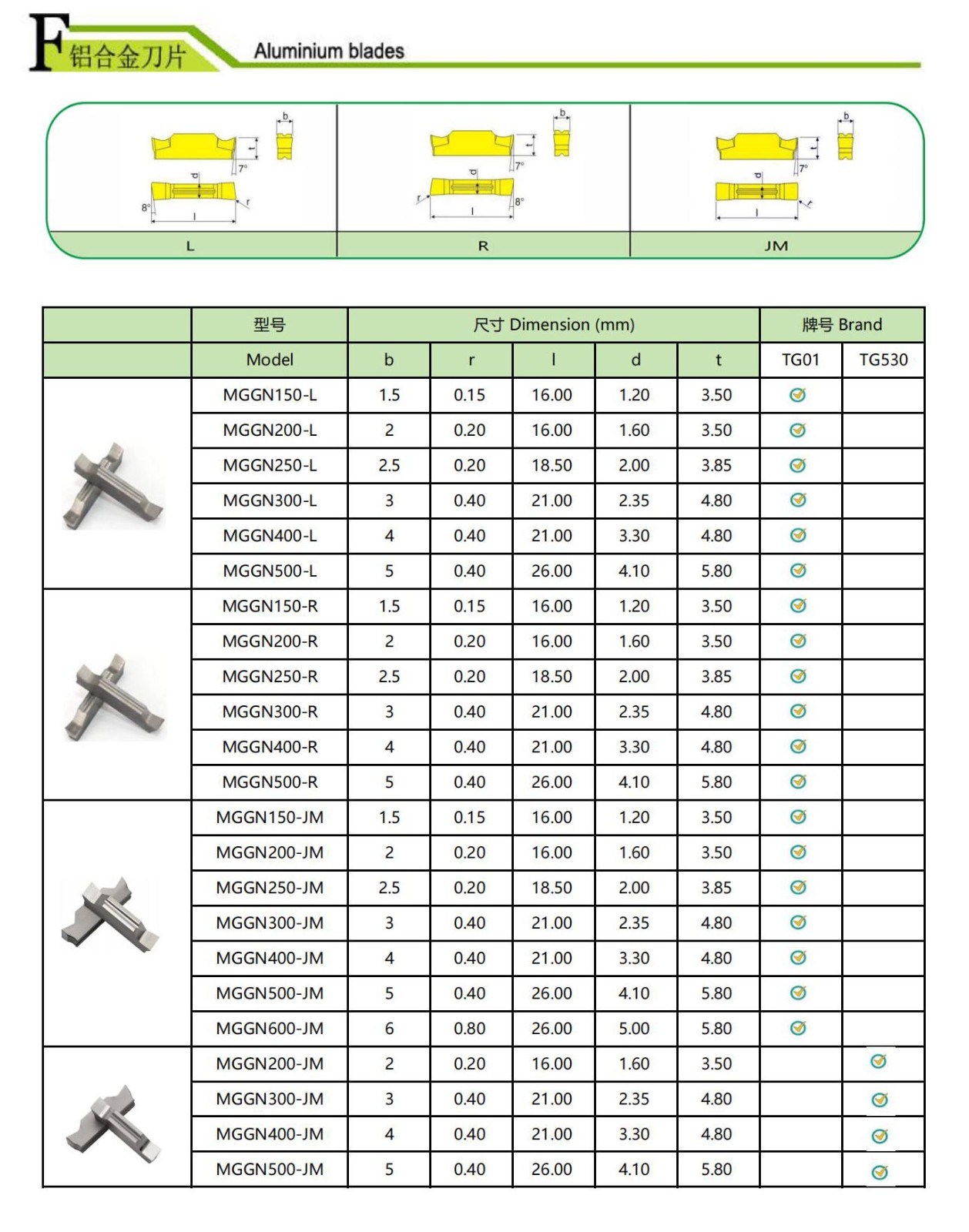

| MGGN Carbide Grooving Inserts for Aluminum Models | |

MGGN150-L | MGGN150-JM |

MGGN200-L | MGGN200-JM |

MGGN250-L | MGGN250-JM |

MGGN300-L | MGGN300-JM |

MGGN400-L | MGGN400-JM |

MGGN500-L | MGGN500-JM |

MGGN150-R | MGGN600-JM |

MGGN200-R | MGGN200-JM |

MGGN250-R | MGGN300-JM |

MGGN300-R | MGGN400-JM |

MGGN400-R | MGGN500-JM |

MGGN500-R | |

Material & Coating

Key Features

Ordering Information:

For accurate pricing and delivery details for our MGGN Carbide Grooving Inserts for Aluminum, please reach out to our sales team. We also provide tailored solutions to fit your unique project needs. Let us help you find the perfect match for your requirements.

About Our Company

Jinan Xinxin Trading Co., Ltd. is a company specializing in a full range of turning tools, milling tools, holemaking tools, carbide cutting tools, machine tool accessories and

other products. At the same time, we accept non-standard product customization and provide perfect tooling solutions for the machining and manufacturing industry.

After years of development, our company firmly believe in the concept of integrity-based, with high-quality service so that the company's products are exported to

Europe, the Middle East, South America, Southeast Asia throughout the world's more than 40 industrialized countries and regions, won the majority of domestic

and foreign customers to support and trust.

Jinan Xinxin Trading Co., Ltd. was founded in 2012, is an excellent comprehensive imported CNC cutting tools agents in Shandong, the company firmly believe in

the concept of good faith, with high quality and attentive service. The company believes in the concept of good faith, with high quality and attentive service. For

the various machining enterprises to supply the world's famous brands of imported CNC cutting tools, machining center tools.

Company Brands

Our company brand IRONROOT series products, with excellent quality and perfect service, strive to reduce the cost of using tools for you.

Main products

Our company, as an important link in the machining field, is following and driving its whole system to run. Our distribution of products has become increasingly systematized, mainly including: Sandvik Coromant sandvikcoromant, Seco, Walter, Kennametal Group Kennametal, Mitsubishi MITSUBISHI, Sumitomo Sumitomo, Kyocera Sholette Kyocera CERATIP, Toshiba, Daijie, Hitachi Tools HITACHI TOOL, ISCAR ISCAR, German cobalt collar Guehring, TEGUTEC TAEGUTEC, KORLOY KORLOY and so on.

Domestic brands: Zhuzhou Diamond Brand, Zigong Great Wall Brand, Zhuzhou Jingcheng Brand, Chengdu Yingge, Ha Yigong, Harbin Tool Factory, Southwest Tools, Chengqi Tools, Shaanxi Cemented Carbide, Zhuzhou Cemented Carbide, Guizhou Yihai, Shanghai Tool Factory and a series of domestic and foreign well-known brands of manufacturers of various types and specifications of CNC blades, Metal lathe tools CNC cutting tools, whole tools, machine-clamped blades, welded blades, toolposts, shank, holder, tungsten steel slats, bars. Tungsten steel slats and bars.

At present, our company's product range includes turning tools, milling tools, drilling tools, tooling systems, carbide cutting tools, machine tool accessories and so on.

Our Customer Reviews

Our products are exported to various countries, including the United States, the United Kingdom, Spain, Italy, Belgium, France, Germany, etc., and are deeply loved and supported by users in these countries. Our products are cost-effective, quality guaranteed, and genuine products.

Thank you very much for watching

Welcome to inquire about the prices, and we will provide you with the best service.

Website: https://www.ironrootcnctools.

Whatsapp/Mobile: +86 13969129141

Email: lronroot190@gmail.com