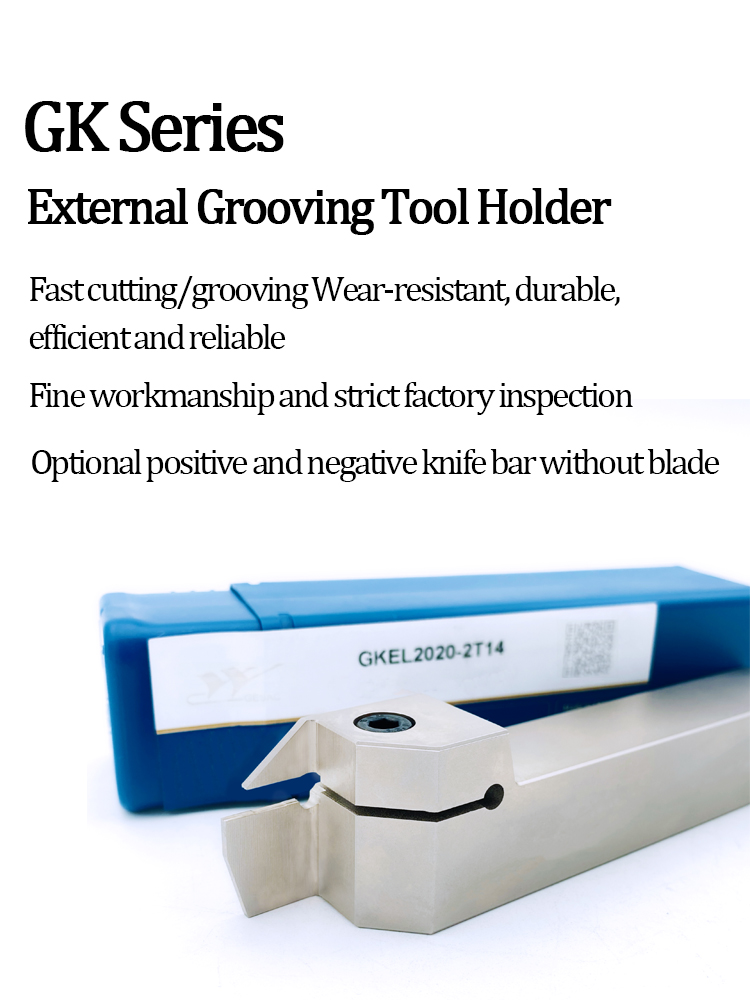

GK Series External Grooving Tool Holder Minimum Order of 1 Piece

The GK series tool bar adopts a composite coating process and multi-level surface treatment technology to significantly improve the wear resistance and service life of the tool. Actual measured data shows that the cutting life of the tool bar is more than 50% longer than that of traditional tools when processing high-hardness materials such as hardened steel (HRC62). Its spring steel structure design combined with the extended blade effectively reduces the processing vibration amplitude by 40%, which is especially suitable for scenes with strict stability requirements such as crankshaft vibration prevention processing and titanium alloy pipe precision cutting.

Modular design is another highlight of this series. It supports switching between multiple scenes such as outer circular grooves, inner hole grooves, and end face grooves. The tool bar specifications cover the needs of mainstream models.

Industry application: driving efficiency leaps in key areas

In the field of automobile manufacturing, the GK series toolholders have been successfully applied to the gear shaft grooving process. By optimizing cutting parameters and tool paths, batch processing efficiency has been improved by 30%. A head parts supplier reported that the introduction of this tool reduced the processing cost of each piece of its crankshaft production line by 18%, while the surface roughness was stably controlled at Ra≤0.8μm8.

The aerospace field has also benefited significantly. Traditional titanium alloy pipe processing relies on grinding wheel cutting, which has problems of insufficient precision and material loss. The GK series achieves one-time forming and cutting through customized cutting solutions, shortens the processing cycle by 45%, and reduces waste generation. An aviation equipment manufacturer said that the tool has passed 200 hours of continuous high-intensity processing tests, and the chipping rate is close to zero37.

Industry analysts point out that the launch of the GK series marks the entry of external cylindrical grooving tools into the "high-precision full-scenario" era. Its technical characteristics not only meet the current manufacturing industry's ultimate pursuit of efficiency and cost, but also provide forward-looking processing solutions for emerging fields such as the miniaturization of 5G communication equipment and the lightweighting of new energy vehicles. With the continuous release of global production capacity, this product is expected to become a benchmark in the precision cutting tool market.