ISO-Certified Internal Grooving Holder for CNC Lathe - 10mm Shank & High-Pressure Cooling

As the demand for efficient cutting tools in the precision machining industry continues to grow, a new generation of internal groove turning toolholder technology has achieved a key breakthrough. This product significantly improves machining efficiency and tool life in aerospace, automotive manufacturing and other fields through integrated high-pressure cooling system and modular design.

Core technology highlights

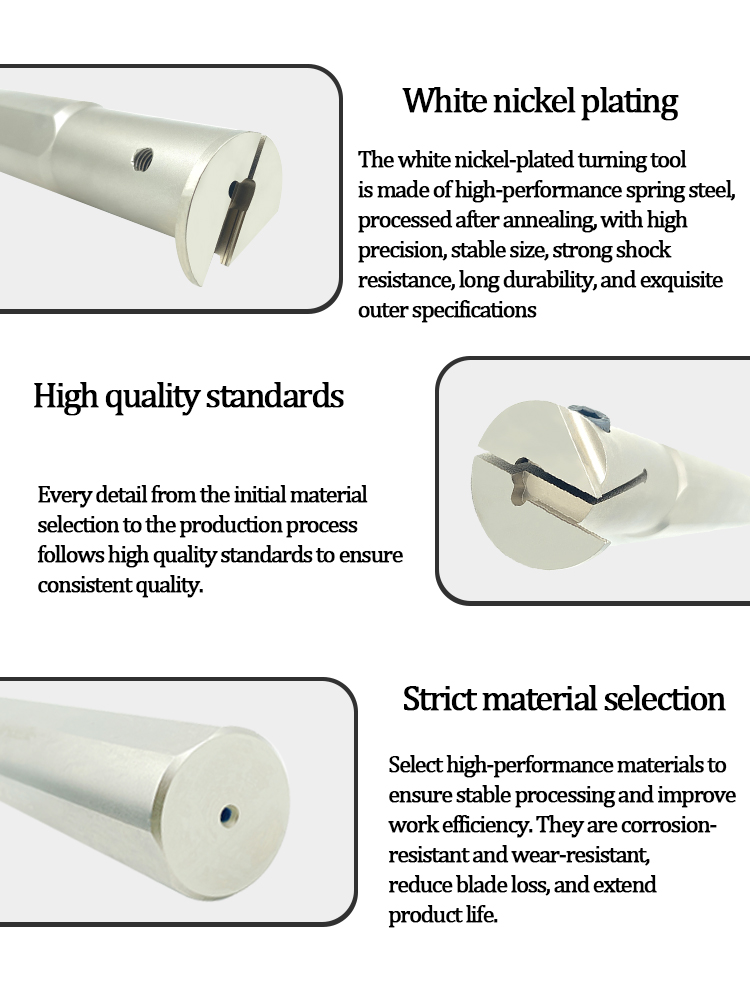

Optimization of high-pressure internal cooling technology

Adopting a ≥70Bar dual-channel cooling system, the coolant outlet is precisely aligned with the cutting edge, effectively reducing the cutting temperature by 30%. Laboratory tests show that when processing stainless steel (1.4404), the tool life is increased by 187% compared with the traditional external cooling system.

Modular fast tool change design

Supports ISO 13399/DIN 4984 standard interface to achieve second-level replacement of blades and tool bars. This design is compatible with 0.4-5mm blade grooves and can cover full-size processing requirements from microelectronic components to heavy hydraulic cylinders.

Vibration-resistant heavy-duty structure

The box-section tool bar is combined with a carbide matrix, with a 40% increase in rigidity. It can still maintain a processing accuracy of ±0.005mm under intermittent cutting conditions, and is particularly suitable for deep hole groove processing of difficult-to-process materials such as titanium alloys.

Industry application evidence

Automobile gearbox manufacturing: In a gearbox input shaft processing case, after using super-hard PCBN coated inserts, the number of single-blade processing times increased from 80 to 230 times, and the efficiency increased by 73%.

Aerospace field: Successfully applied to the processing of the inner wall groove of the combustion chamber of an aircraft engine, achieving a surface roughness of Ra0.8μm, meeting the requirements of AS9100D aviation quality certification.

Technical certification and standardization

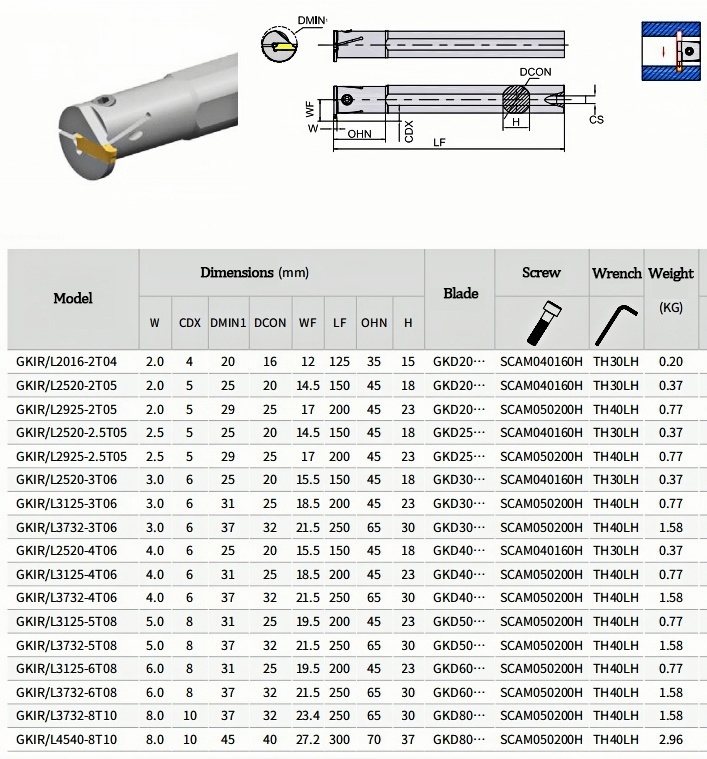

This product has passed ISO 9001 quality management system and IATF 16949 automotive industry certification. The tool holder size covers a diameter range of 8-32mm and is compatible with the VDI turret interface of mainstream CNC machine tools such as Mazak and DMG Mori.

Industry impact and future trends

According to the "2023-2028 Global Grooving Tool Market Report", the market share of cutting tools with integrated internal cooling systems has an annual growth rate of 12.3%, and the market size is expected to exceed US$2.9 billion in 2028. This technological breakthrough will further promote the upgrade of the precision manufacturing industry to efficient and environmentally friendly processing.