MV series compound external turning tool is an excellent choice for precision machining

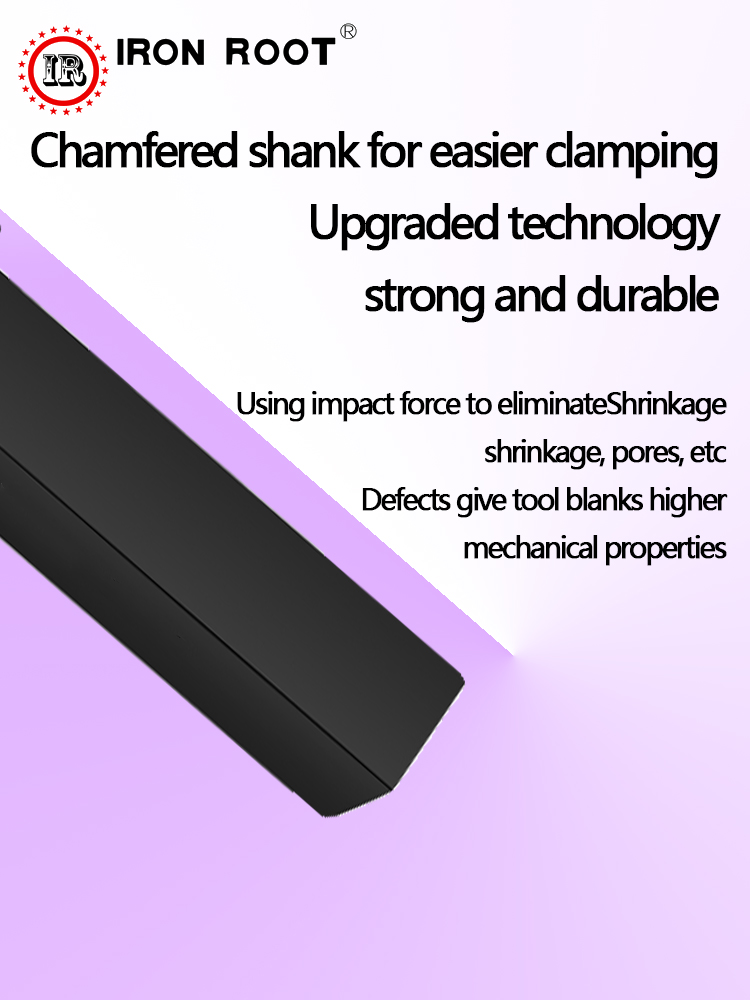

The MV series of external turning tools adopt advanced manufacturing technology to ensure excellent cutting performance and durability. Its unique blade design and material selection enable this series of products to maintain extremely high precision and stability during the processing. Whether it is processing materials such as steel, stainless steel or cast iron, the MV series can easily cope with it and show excellent cutting results.

The MV series not only excels in performance, but its multifunctional design also meets the diverse needs of different users. This series of products is suitable for a variety of processing scenarios, including but not limited to:

Mechanical manufacturing: In the processing of mechanical parts, the MV series can achieve high-precision external cylindrical turning to ensure the dimensional accuracy and surface finish of the parts.

Automobile manufacturing: For the production of automotive parts, the MV series provides efficient processing solutions, which can quickly complete complex processing tasks and improve production efficiency.

Aerospace: In the field of aerospace, the precision requirements for parts are extremely high. With its excellent performance, the MV series can meet the industry's strict requirements for high-precision processing.

Mold manufacturing: The processing of molds requires extremely high precision and surface quality. The advantages of the MV series in external cylindrical turning make it an ideal choice for mold manufacturing.

The launch of the MV series of external turning tools marks an important step forward in the field of metalworking tools. We are committed to providing users with the best quality products and the most complete services, helping enterprises stand out in the fierce market competition. Choosing the MV series means choosing efficiency, precision and reliability. Let us work together to create a better future!