MFR Series Carbide Boring Tool - 0.8-10mm Precision CNC Anti-Vibration Design for Hardened Steel/Titanium/Stainless Steel

1. Core technology highlights

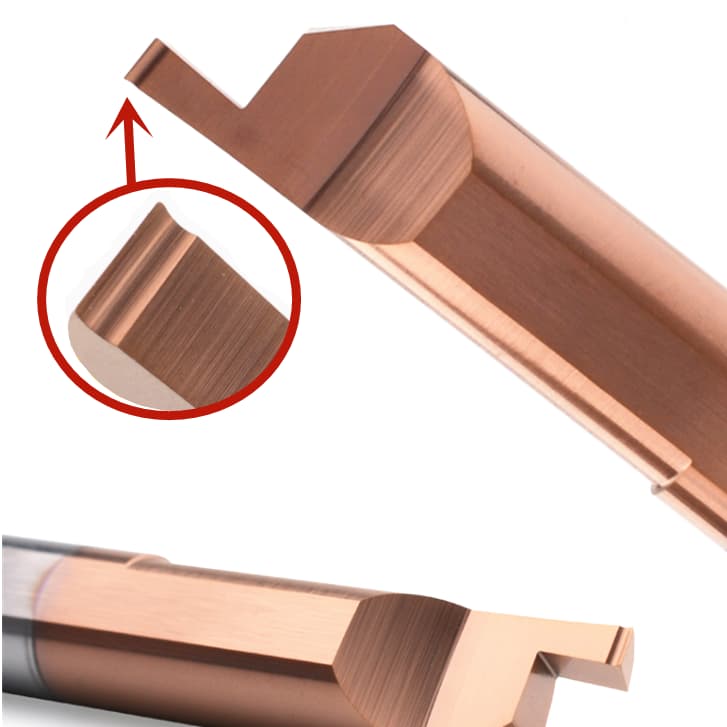

Material and process

Using high-quality tungsten steel alloy or cemented carbide material, the hardness can reach HRA92 or above, and the wear resistance and impact resistance are significantly better than ordinary high-speed steel.

Special surface coating treatment (such as nano blue coating) further reduces the friction coefficient and extends the tool life to 3-5 times that of ordinary tools.

Structural design

Axial groove chip removal design: effectively reduces cutting resistance and improves processing efficiency, especially suitable for deep hole processing.

Anti-vibration tool bar technology: The built-in shock-absorbing structure can reduce the vibration amplitude by 50%, ensuring that the aperture tolerance is controlled within ±0.005mm.

Modular tool head: supports rapid replacement of 1-10mm diameter range, adapting to different working conditions.

2. Typical application scenarios

Precision machinery field

Aerospace: Processing fuel nozzle micropores (minimum aperture 0.8mm).

Medical equipment: Finishing of titanium alloy artificial joint inner holes (surface roughness Ra≤0.4μm).

Complex working conditions challenge

Machining of stainless steel 304 material: cutting speed can reach 120m/min, and chip breaking effect is excellent.

45° blind hole expansion: the taper design of the tool body ensures processing stability and avoids tool tip damage.

3. Market verification data

User feedback

An automotive parts manufacturer uses the MFR3.5 model to process connecting rod oil holes, with a tool life of 1,200 pieces/blade and a cost reduction of 37%.

When processing the M1.6 threaded holes of the mobile phone middle frame in the 3C industry, the yield rate increased from 85% to 99.2%.

Industrial-grade tools designed for 0.8-10mm micro-hole precision machining, made of carbide tungsten steel and modular anti-vibration structure, suitable for high-precision machining scenarios such as aerospace, medical equipment, etc.

Core selling point

Military-grade material

Adopting HRA92+ hardness tungsten steel alloy substrate, combined with nano-blue coating technology, the service life is 3-5 times that of ordinary tools

The surface friction coefficient is reduced by 40%, and the cutting speed is increased to 120m/min (stainless steel working conditions)3

Seismic structure design

Built-in hydraulic damping shock absorption system, vibration amplitude is reduced by 50%

The machining hole diameter tolerance is stable at ±0.005mm, and the surface roughness Ra≤0.4μm

Technical Parameters

| D | MFR | L | L1 | T/Grooving depth | Minimum aperture |

| 4 | D4-MFR 4 B0.75 L15 | 50 | 15 | 1.2 | 5 |

| D4-MFR 4 B1.0 L15 | 50 | 15 | 1.5 | 5 | |

| D4-MFR 4 B1.5 L15 | 50 | 15 | 2.8 | 5 | |

| 5 | D5-MFR 5 B0.75 L22 | 50 | 22 | 1.2 | 6 |

| D5-MFR 5 B1.0 L22 | 50 | 22 | 1.5 | 6 | |

| D5-MFR 5 B1.5 L22 | 50 | 22 | 1.5 | 6 | |

| D5-MFR 5 B2.0 L22 | 50 | 22 | 3.8 | 6 | |

| 6 | D6-MFR 6 B0.5 L20 | 50 | 20 | 1 | 8 |

| D6-MFR 6 B1.0 L22 | 50 | 22 | 1.5 | 8 | |

| D6-MFR 6 B1.5 L22 | 50 | 22 | 2.5 | 8 | |

| D6-MFR 6 B2.0 L22 | 50 | 22 | 3 | 8 | |

| D6-MFR 6 B2.5 L22 | 50 | 22 | 4.6 | 8 | |

| D6-MFR 6 B3.0 L22 | 50 | 22 | 6 | 8 | |

| D6-MFR 6 B3.0 L30 | 50 | 30 | 6 | 8 | |

| 8 | D8-MFR 8 B1.0 L25 | 60 | 25 | 3.5 | 10 |

| D8-MFR 8 B1.5 L25 | 60 | 25 | 3.5 | 10 | |

| D8-MFR 8 B2.0 L25 | 60 | 25 | 3.5 | 10 | |

| D8-MFR 8 B2.5 L22 | 60 | 22 | 3.5 | 10 | |

| D8-MFR 8 B3.0 L30 | 60 | 30 | 3.5 | 10 |

Application scenarios

Aerospace

0.8mm micro-hole processing of fuel nozzles (special cooling fixture is required)

Medical equipment

Precision boring of inner holes of titanium alloy artificial joints (surface finish Ra0.4μm

Automobile manufacturing

Batch processing of oil holes in engine connecting rods (tool life 1200 pieces/blade)