DLC Series Carbide Square End Mill, Diamond-Like Coating, End Mill for Aluminum, Copper, Magnesium Alloys, High Silicon Aluminum, Composite Materials

High hardness and wear resistance

Carbide is sintered from tungsten carbide and cobalt. Its hardness is much higher than that of high-speed steel. It can keep the cutting edge sharp for a long time. It is especially suitable for processing high-hardness materials such as titanium alloy and high-temperature alloy. The tool life can be increased by 3-5 time

Excellent thermal stability

Carbide tools can still maintain stable cutting performance under high temperature and high pressure environment, avoiding the decrease in precision caused by thermal deformation, and are suitable for high-speed cutting.

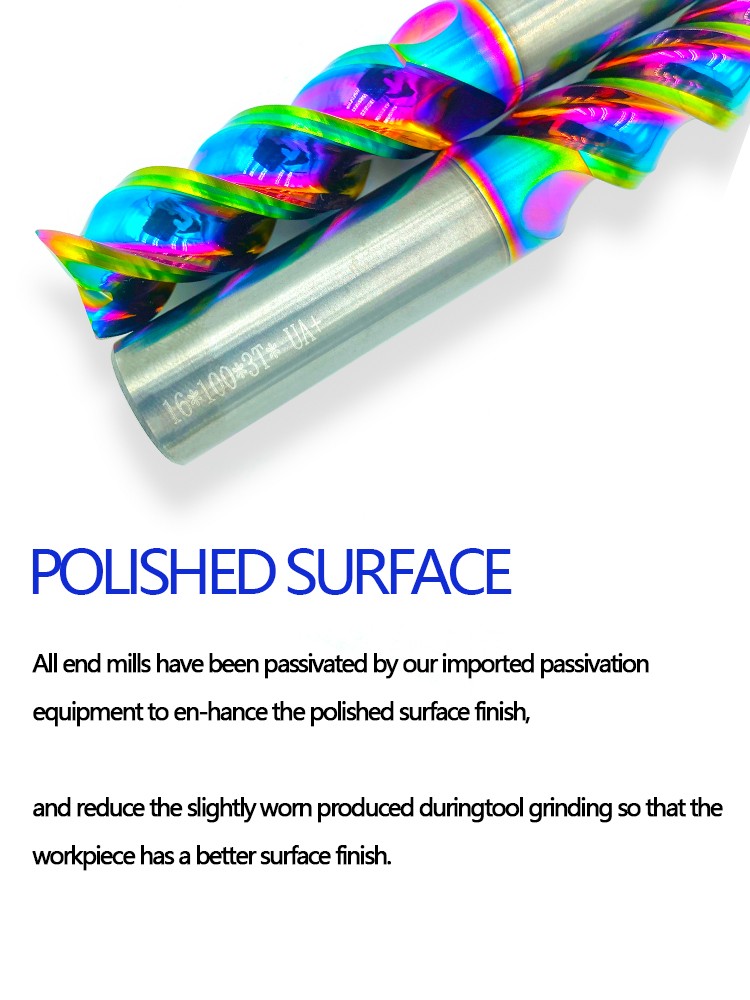

Chip removal and cooling design

For example, the CoolStar series end mills are equipped with multiple internal cooling holes and optimized chip removal grooves to enhance the cooling effect and reduce chip blockage, improving the efficiency of deep cavity processing9.

1. Core Features of the Product

Designed for Colorful Aluminum Processing

This series of end mills is optimized for aluminum alloys (especially colorful aluminum with high gloss mirror requirements). The DLC coating (diamond-like carbon coating) achieves low friction coefficient and high wear resistance, ensuring that the processed surface is scratch-free and the finish reaches the mirror effect.

Coating advantages: The hardness of the DLC coating is close to that of diamond, which can reduce the sticking phenomenon during aluminum processing and extend the tool life. It is especially suitable for high-precision CNC machine tool processing.

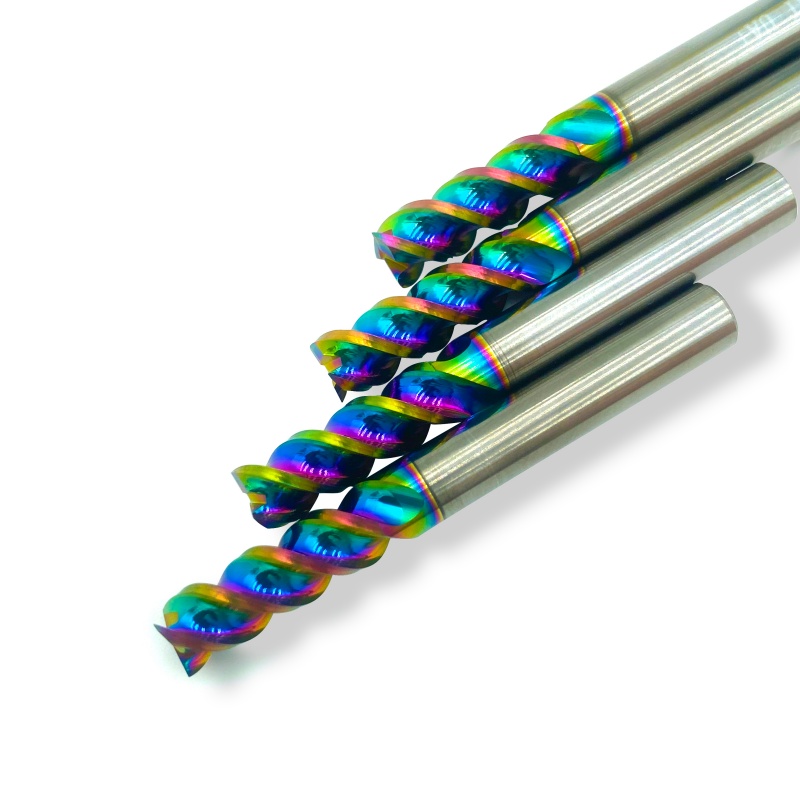

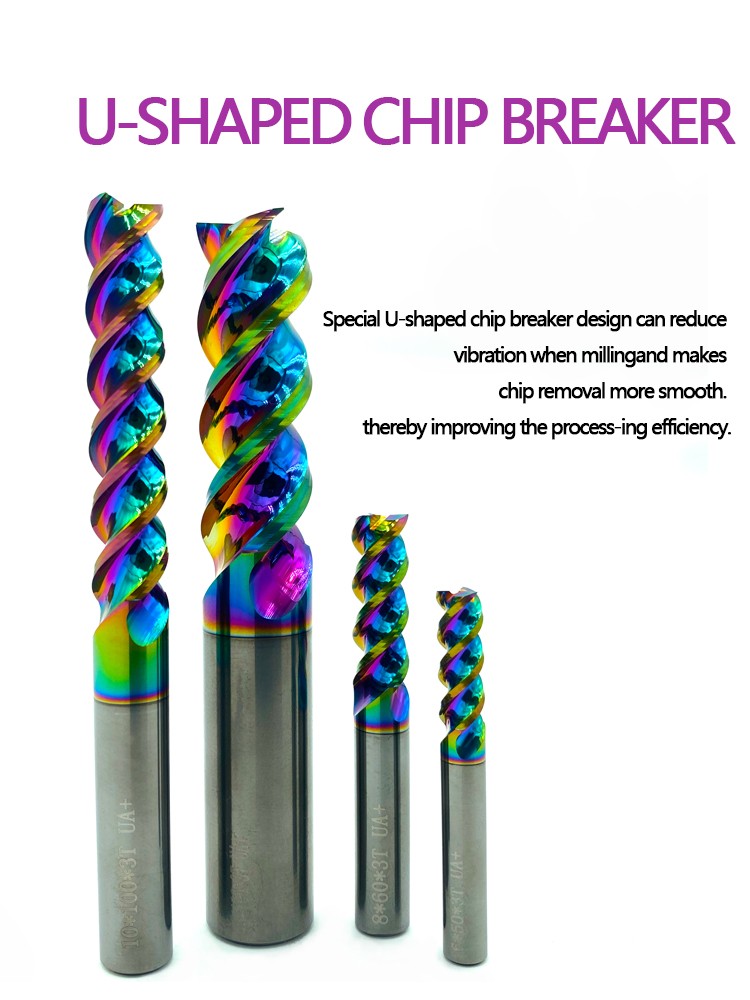

Three-blade structure and carbide substrate

Three-blade design: balances cutting efficiency and chip removal performance, suitable for high-speed roughing and finishing of aluminum alloys.

Carbide material: uses tungsten steel substrate (tungsten carbide + cobalt), with high hardness, high temperature resistance, and can withstand high speed (such as linear speed 80-200m/min).

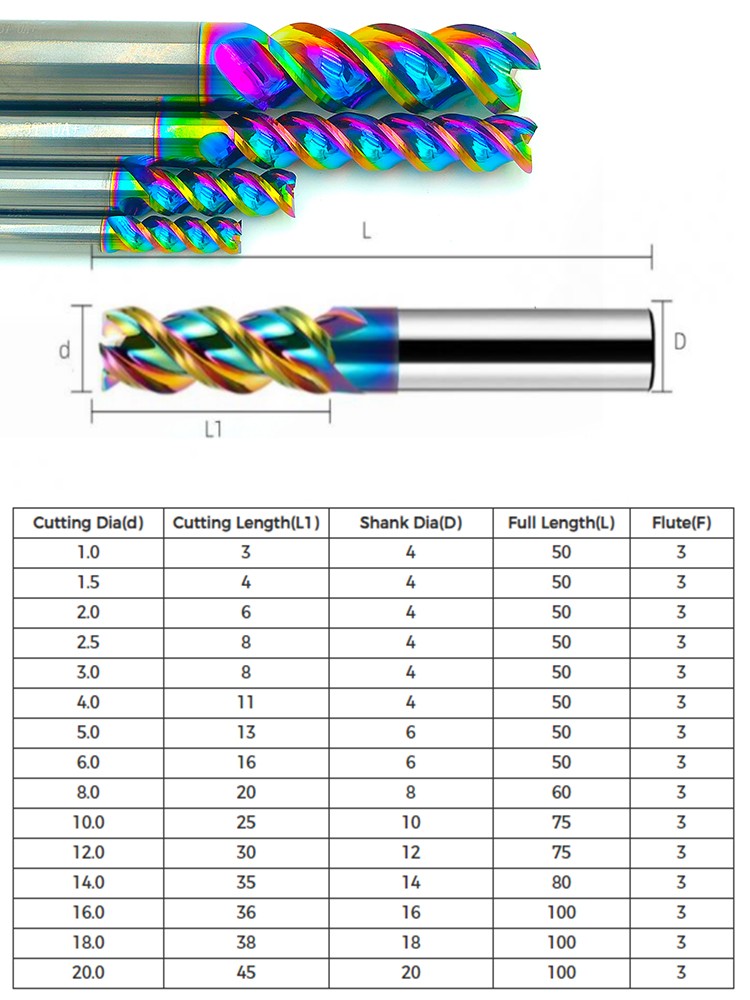

Customized specification adaptation

Model example: The model shown on the JD product page is 5.015D6*50L, corresponding to a blade diameter of 5.0mm, a blade length of 15mm, a shank diameter of 6mm, and a total length of 50mm, which is suitable for small precision parts processing.

Optional parameters: Support customized requirements for different diameters, blade lengths, and coating thicknesses.

2. Application scenarios and advantages

Mirror polishing processing

DLC coating combined with a three-blade spiral groove design effectively reduces cutting heat and burr generation, and is suitable for scenes with extremely high requirements for surface finish such as mobile phone housings and 3C product accessories.

Efficient processing performance

High feed rate: The three-blade structure can increase the metal removal rate (MRR) and shorten the processing cycle.

Deep cavity processing support: Long neck models (such as 50L total length) are suitable for narrow spaces or deep groove milling.

Industry coverage

Mainly used in consumer electronics, automotive parts (such as aluminum alloy wheels), mold manufacturing and other fields, especially suitable for decorative aluminum processing that requires a colorful gloss effect.