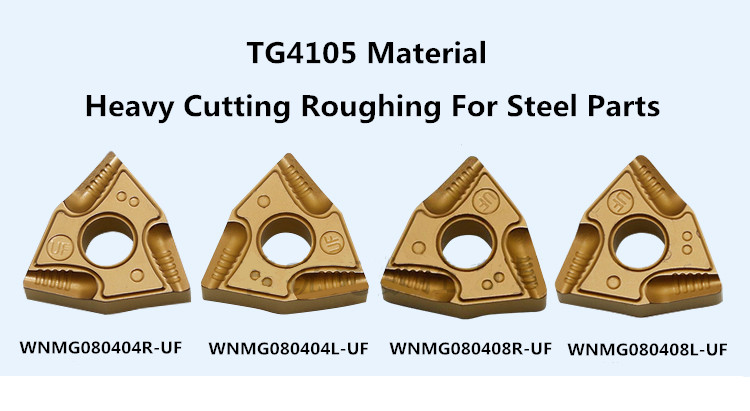

WNMG08 Turning Carbide Insert CVD/TiN Coated CNC Lathe Tool Stainless Steel/Hardened Steel Cutting

WNMG08 carbide inserts offer several advantages for steel machining:

Versatile Geometry:

They feature a double-sided trigon design suitable for medium to semi-roughing operations

on steel and cast iron, providing a stable cutting edge .

Multiple Cutting Edges:

With six effective cutting edges, WNMG08 inserts allow for increased material removal and

reduced downtime for tool changes .

Efficient Chip Control:

The design includes chip breakers on both faces for improved chip evacuation, reducing

the risk of chip jamming .

Durable Material:

Made from tungsten carbide, these inserts are hardwearing and offer extra protection with

hardwearing coatings .

Cost-Effective:

The ability to recycle dull edges and the high recovery rate of carbide materials contribute to

cost reduction .

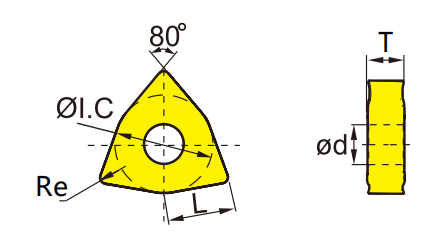

The WNMG08 carbide insert is a double-sided trigon insert designed for medium to semi-roughing operations on steel and cast iron. With six effective cutting edges, it offers efficient material removal and extended tool life. This insert features a 12.7 mm inscribed circle diameter (IC), a 0.4 mm corner radius (Rε), and is secured via a cylindrical fixing hole, ensuring stable clamping during operation. The WNMG08 insert is also equipped with chip breakers on both faces for improved chip control and reduced risk of chip jamming. Its negative geometry provides a strong cutting edge that is less prone to deflection, making it suitable for a variety of steel materials. This insert is recognized for its high hardness, good hot hardness, excellent wear resistance, and the ability to achieve higher cutting speeds, contributing to enhanced production efficiency and shorter production cycles.

| Model | L | ØI.C | T | Ød | Re |

| WNMG060404 | 6.5 | 9.525 | 4.76 | 3.81 | 0.4 |

| WNMG060408 | 6.5 | 9.525 | 4.76 | 3.81 | 0.8 |

| WNMG060412 | 6.5 | 9.525 | 4.76 | 3.81 | 1.2 |

| WNMG080404 | 8.7 | 12.7 | 4.76 | 5.16 | 0.4 |

| WNMG080408 | 8.7 | 12.7 | 4.76 | 5.16 | 0.8 |

| WNMG080412 | 8.7 | 12.7 | 4.76 | 5.16 | 1.2 |

The blade adopts a multi-layer composite coating process. The bottom layer is based on a high-toughness TiCN coating, the middle layer forms a heat-insulating barrier through nano-scale Al₂O₃ crystals, and the surface layer is covered with a golden TiN wear-resistant layer. This "hard and soft" structural design reduces the back face wear rate of the tool by 50% when machining hardened steel (HRC62), while improving the anti-chipping performance by 40%.

According to different working conditions, the blade provides three chip breaker solutions:

The wide-edge chip breaker (WF type) is suitable for the finishing of stainless steel and low-carbon steel, and achieves stable chip removal at a feed rate of 0.15-0.3mm/r;

The double-sided chip breaker (NF type) is specially designed for semi-finishing of hardened steel and alloy steel, and the positive rake edge effectively reduces the cutting force;

The reinforced chip breaker (PR type) is aimed at the intermittent cutting scene of cast iron, and the edge strength is enhanced by the negative chamfer design.