ER extension rod milling machine auxiliary straight handle

The advantage of the extension rod is that it solves the space limitation by "link extension", while the performance depends on the support of material science and structural design. When choosing, it is necessary to match the corresponding materials (such as steel/aluminum/plastic), interfaces (taper/thread) and structures (rigidity/flexibility) according to the requirements of load, accuracy, environment, etc., to maximize its value of "remote operation".

Structural features

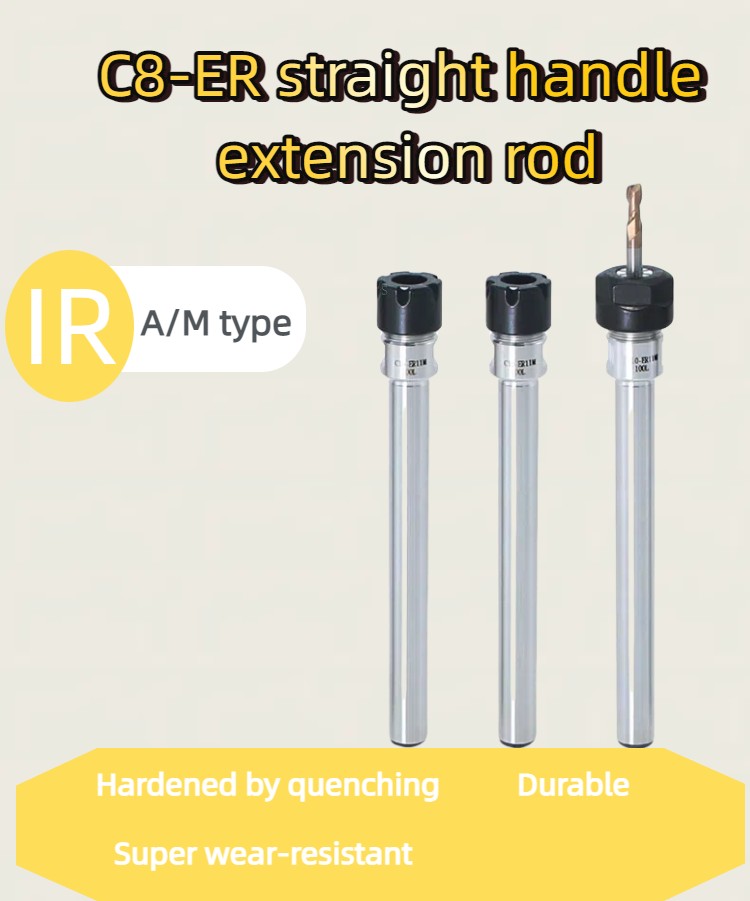

Usually adopts a straight shank design, and the shank diameter has a variety of specifications, such as C8, C10, C12, C16, C20, C25, C32, etc. Different shank diameters are suitable for different machine tool spindle interfaces and processing requirements.

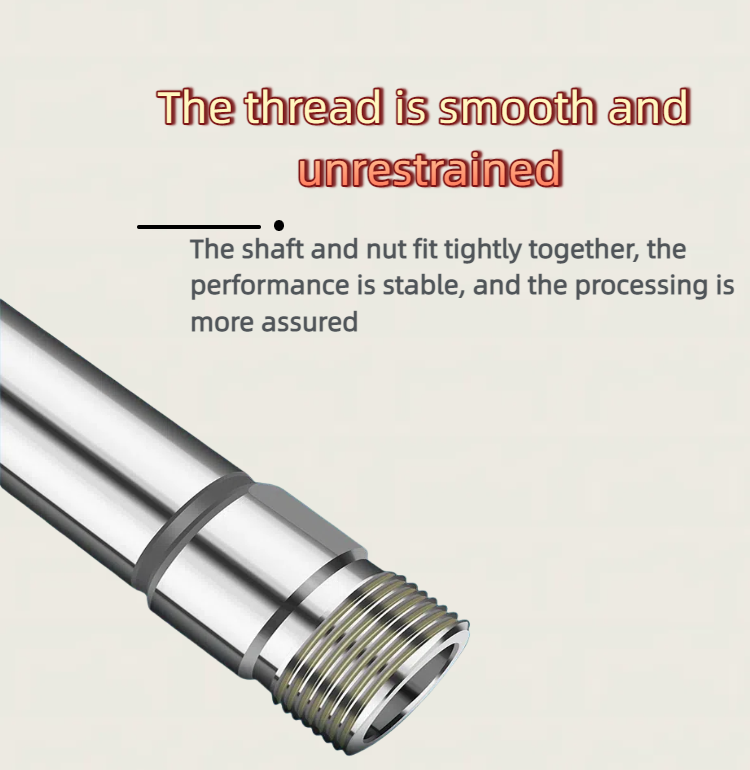

ER chucks are used together. ER chucks have good elasticity and can clamp drills, reamers, end mills, taps and other tools. The tool is clamped by tightening the nut, and the clamping force is strong, which can ensure the stability of the tool during processing.

Some ER extension rods may have a built-in top screw structure, which can limit and adjust the tool length to improve work efficiency.

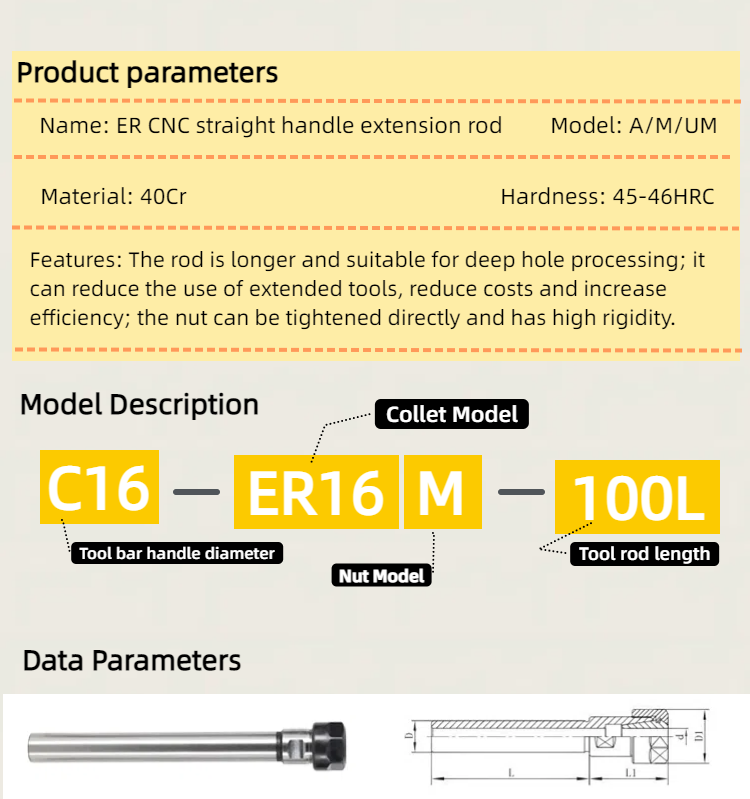

The model usually includes information such as shank diameter, matching chuck and nut model, shank length, etc. For example, in C20 - ER16 - 50, C20 means the shank diameter is 20mm, ER16 means the matching nut and chuck is ER16, and 50 means the shank length is 50mm.

There are many different length specifications to choose from to meet different processing depth requirements. Common lengths include 50mm, 70mm, 100mm, 150mm, 200mm, etc. Even longer specifications are available.

Product parameters

Size parameters:

Handle diameter: Common specifications include C8, C10, C12, C16, C20, C25, C32, etc., indicating the diameter of the straight handle.

Working length: that is, the length of the extension rod, there are many options, such as 50mm, 70mm, 100mm, 150mm, 200mm, etc. (different lengths are suitable for different processing depth requirements).

Applicable chuck specifications: such as ER11, ER16, ER20, ER25, ER32, etc. (determines the type and size range of the tool that can be clamped).

Precision parameters:

Total accuracy (T.I.R.): usually up to ≤0.005mm, ensuring the accuracy and stability of processing.

Chuck accuracy (T.I.R.): There are different levels such as 0.015mm, 0.008mm, 0.005mm, etc., which affects the accuracy of the tool after installation.

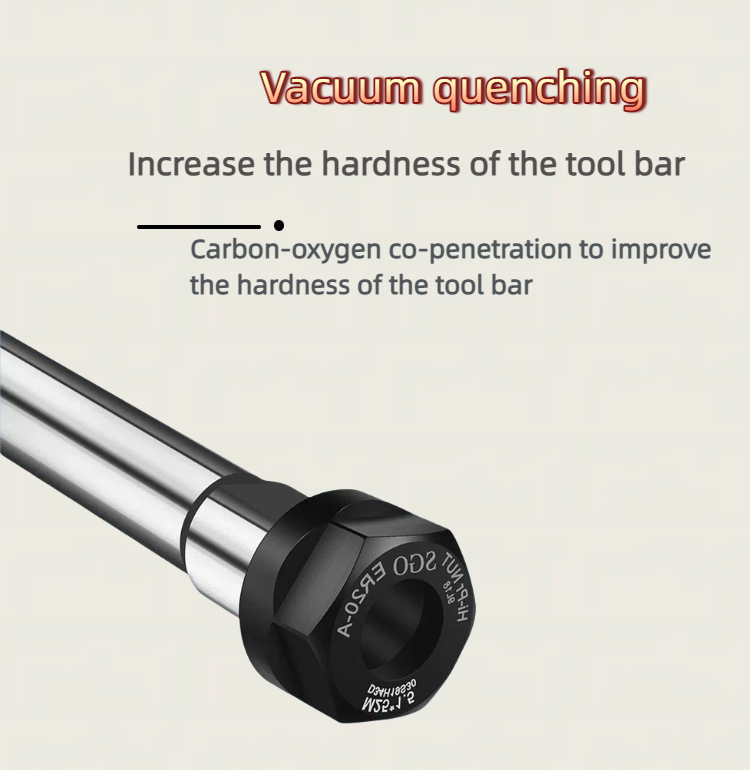

Material parameters: Common materials include high carbon steel, stainless steel, titanium alloy, etc. After treatment, high carbon steel becomes harder and more wear-resistant; stainless steel has good corrosion resistance; titanium alloy has high strength, low density and corrosion resistance, but is more expensive.

Nut Model

The matching nut is the key component to achieve tool clamping. Its main function is to shrink the ER collet and clamp the tool through the pressure generated by tightening.

The nut model usually corresponds to the ER collet specifications, for example:

ER11 nut: suitable for ER11 collet, used to clamp tools with a diameter of 1-7mm;

ER16 nut: suitable for ER16 collet, clamping tools with a diameter of 1-10mm;

ER20 nut: suitable for ER20 collet, clamping tools with a diameter of 1-13mm;

And so on, ER25, ER32 and other nuts correspond to larger collets and tools respectively.