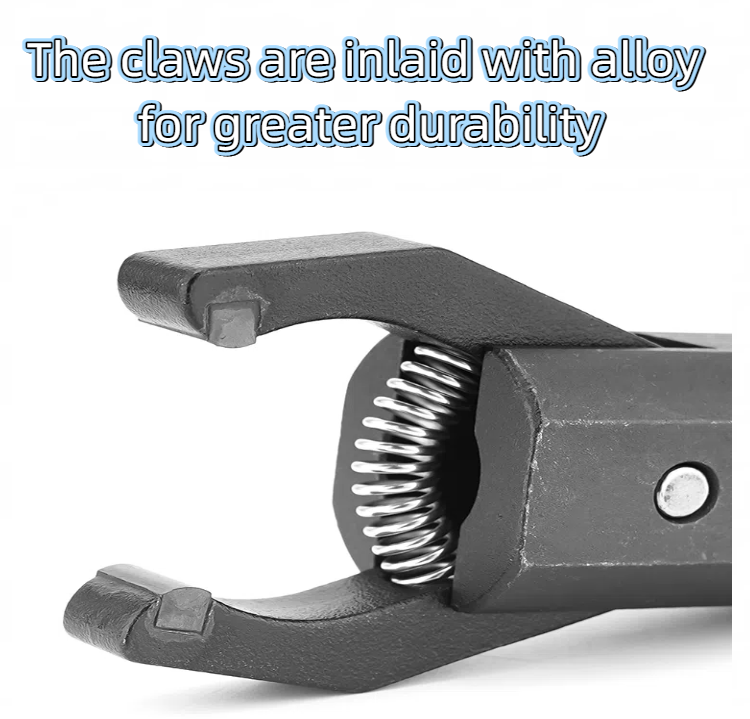

Automatic stripper for CNC lathe with alloy puller fixture

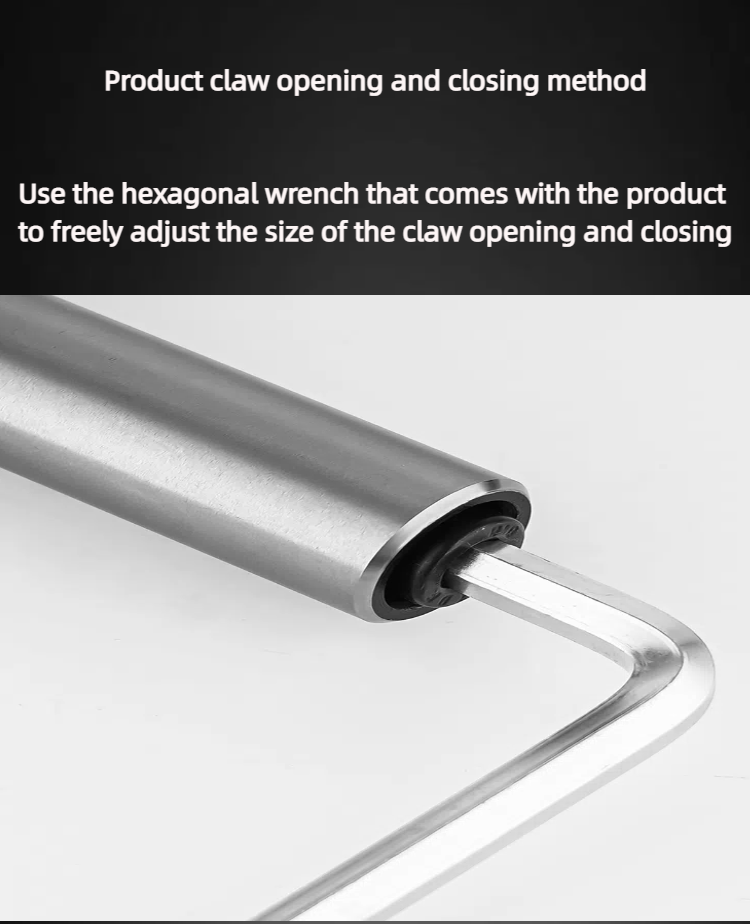

Efficient automation: The spring force and the lead screw are linked to automatically adjust the size and align the center of the bar, so that the sheet material can be accurately fed into the tractor with one click, replacing manual feeding, and the processing efficiency is increased by more than 60%.

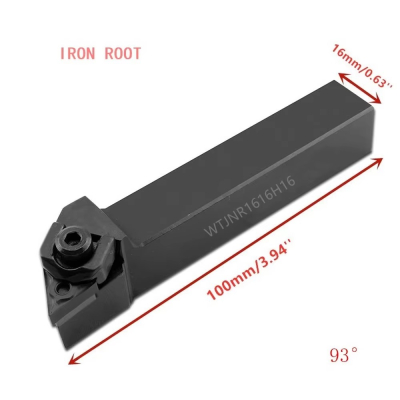

High-precision positioning: The lead screw transmission cooperates with the center alignment mechanism, and the feeding error is ≤0.05mm, ensuring the uniformity of the bar processing benchmark and reducing the scrap rate.

Strong compatibility: It is suitable for a variety of bar specifications (diameter 5-50mm) and sheet materials, and the workpiece type can be quickly switched through parameterized adjustment, with outstanding flexible production capacity.

Low consumption and durability: The alloy tungsten steel inlay structure is wear-resistant, and the spring assembly has no attenuation after 200,000 fatigue tests, and the maintenance cost is reduced by 40% compared with traditional tooling.

Safety integration: The linkage CNC system realizes the interlocking of the entire process of feeding-processing-returning, avoiding the risk of equipment collision caused by manual intervention, and complies with ISO safety certification standards.

Product photos