Description

Report Item

Specification

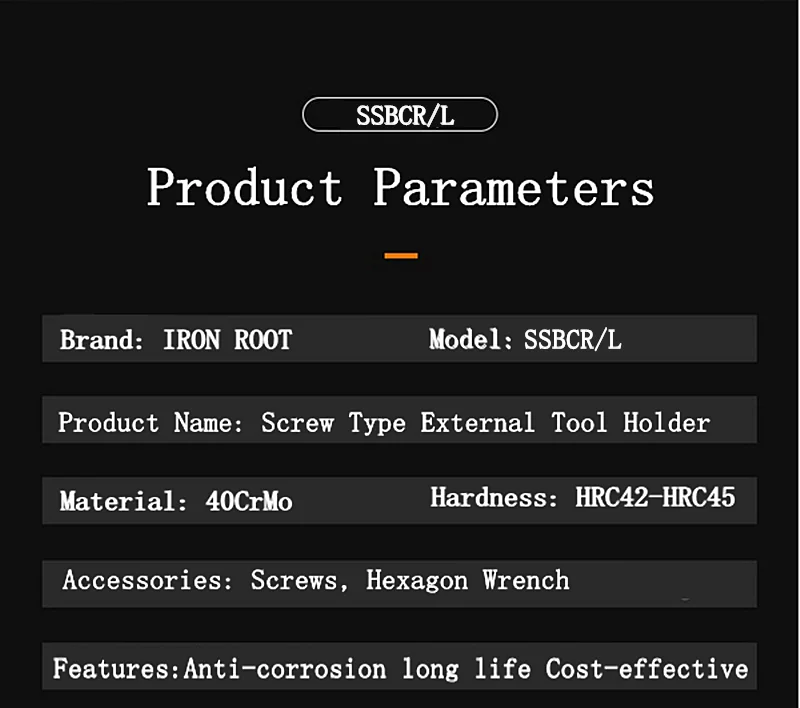

Name: External Turning Tool

Brand: IRON ROOT

Item No.:SSBCR/L

Material quality: 42Cr

Hardness: HRC42~46

Accessories: screw , wrench

Suitable insert:SNMG

Pack: High-grade PE outer box

Feature

1.Not easy to stick tools, more smooth chip removal.

2.The cutter bar is hardened and durable.

3.Refined polishing, fine luster.

4.Imported matrix, tool rod imported 42Cr material.

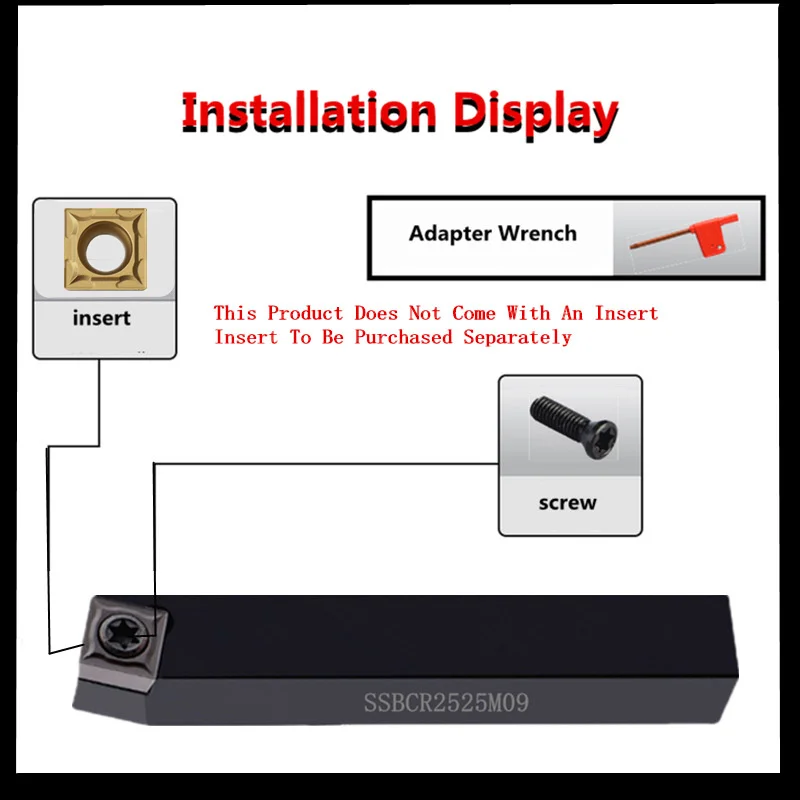

Package Included

Cutter bar and accessories including 1pc screw, wrench.

Note that insert is not included, which needs to be purchased separately.

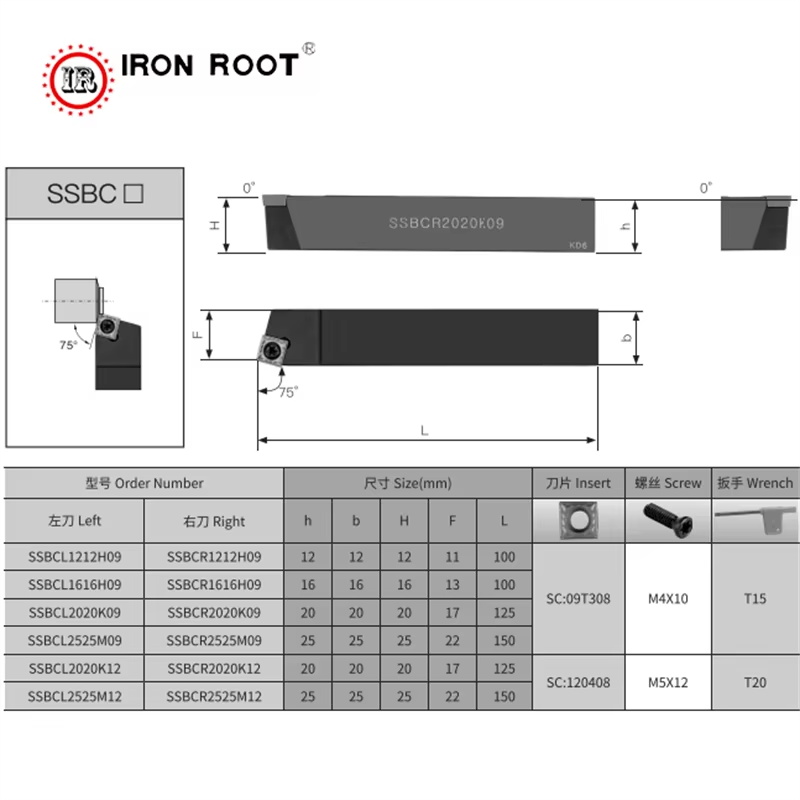

Introducing our 75 Degree Screw Type External Cutting Tool Holders, a comprehensive range of high-performance machining solutions encompassing models SSBCR1212H09, SSBCR1616H09, SSBCR2020K09, SSBCR2525M09, SSBCR2020K12, and SSBCL2525M12. Engineered to meet the rigorous demands of modern metalworking, these tool holders are the perfect blend of precision, durability, and versatility.

Crafted from top-grade alloy steel, these tool holders are built to endure. The robust construction of 42CrMo steel provides exceptional strength and toughness, enabling them to withstand the high forces and vibrations generated during heavy-duty cutting operations. This resilience ensures minimal deformation over time, safeguarding the integrity of your machining processes and reducing the need for frequent replacements.

The defining feature of these tool holders is their 75-degree cutting angle, a carefully optimized geometry that strikes the perfect balance between cutting efficiency and chip control. This angle is particularly well-suited for external turning applications, whether you're performing roughing to rapidly remove material or finishing to achieve a mirror-like surface finish. The 75-degree angle also allows for efficient chip evacuation, preventing chip buildup that could otherwise lead to tool wear and surface imperfections.

The screw-type clamping mechanism is another highlight, offering unparalleled stability and security. By firmly securing the cutting insert in place, it eliminates any risk of slippage during operation, even at high speeds and feeds. This not only enhances the precision of your cuts but also extends the lifespan of your inserts, maximizing your return on investment.

Designed with compatibility in mind, these tool holders are engineered to work seamlessly with a wide range of standard inserts. The designations such as H09, K09, K12, and M12 correspond to specific insert sizes and geometries, allowing you to easily swap out inserts to suit different materials and machining requirements. Whether you're working with hard metals like steel and stainless steel or softer materials like aluminum and brass, these tool holders have you covered.