40Cr alloy steel high precision CNC tap chuck for machining center/CNC milling machine

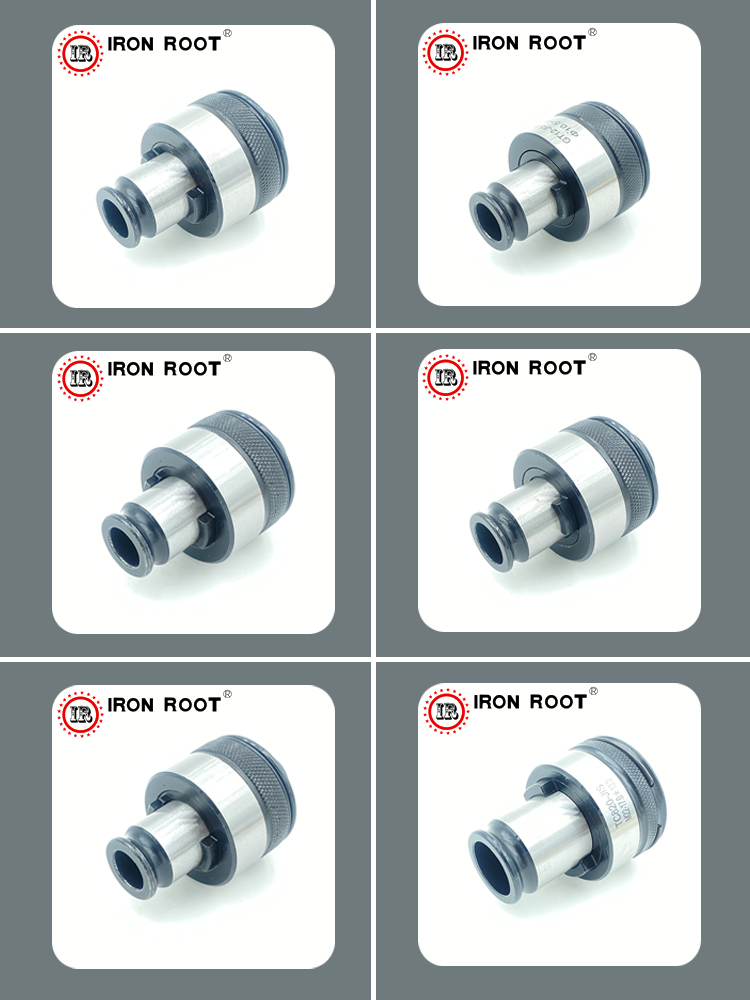

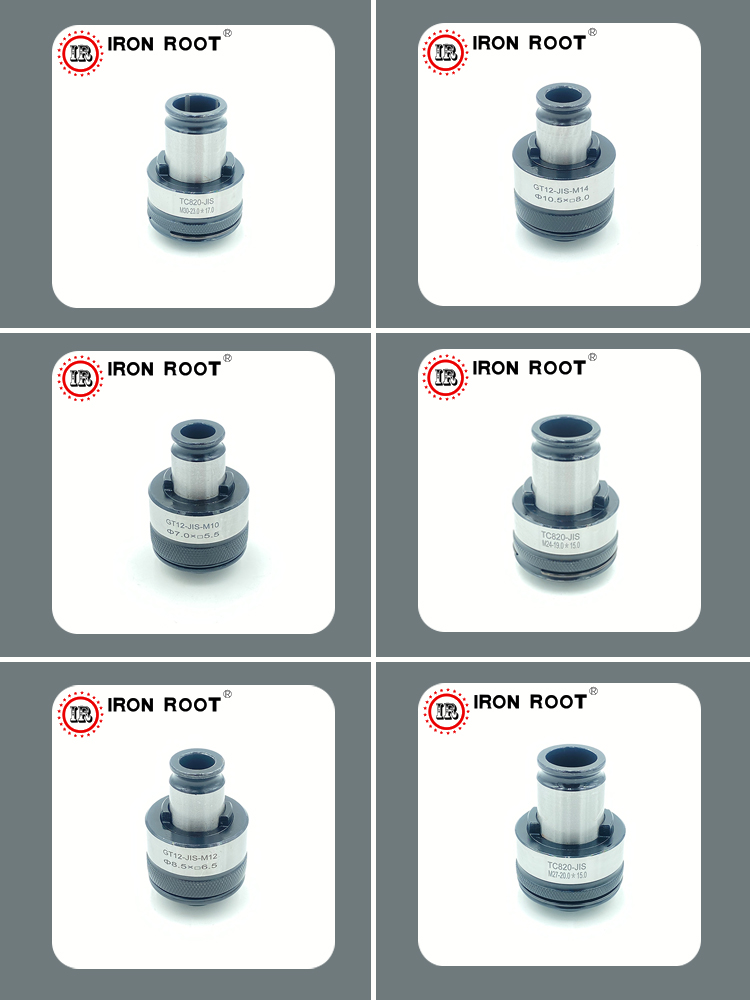

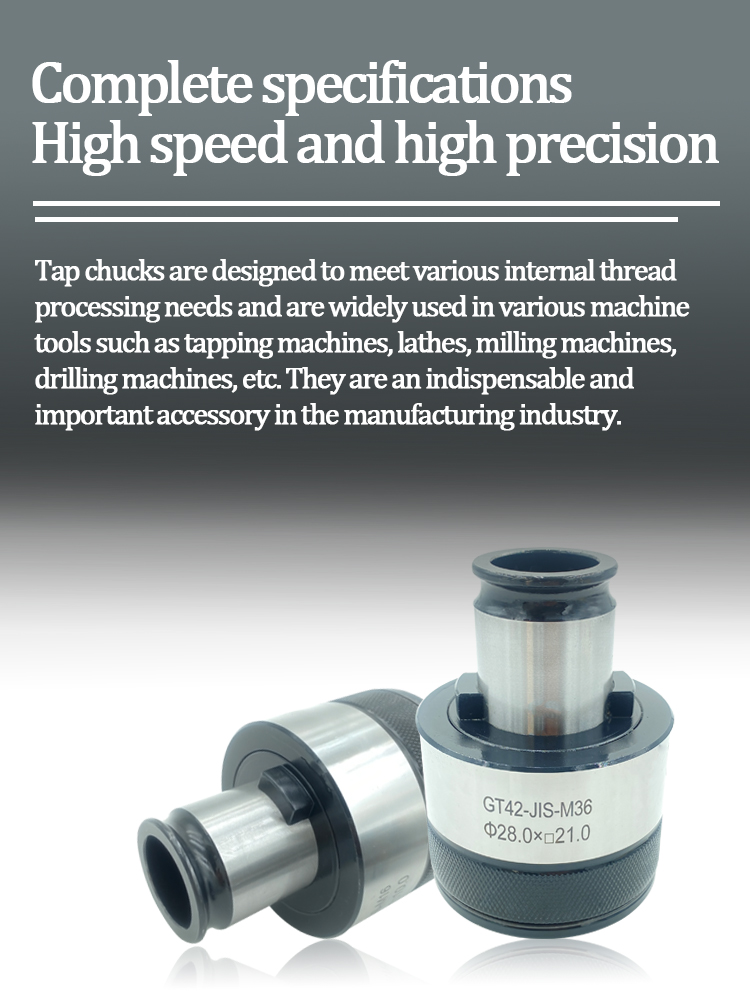

As a key functional component in the field of metal processing, the core value of tap chucks is reflected in the process efficiency of precision transmission and dynamic adaptation. This product realizes efficient docking between taps and machine tool spindles through a modular clamping structure. Its internal structure usually adopts a split jaw design, which can adapt to the radial runout tolerance of taps of different diameters with a spring preload device. In CNC machining scenarios, this type of chuck can be quickly replaced with the tool handle through the ER series taper interface. For example, the ER25 chuck is compatible with M3-M12 specification taps, and its 0.01mm level of repeat positioning accuracy can meet the processing requirements of five-axis linkage machine tools.

In terms of material technology, high-end tap chucks generally use tungsten steel matrix composite surface nitriding treatment technology, and the surface hardness can reach HRC65 or above. This composite structure significantly improves the wear resistance of key contact surfaces while maintaining overall toughness. For difficult-to-process materials such as titanium alloys, the specially designed spiral chip groove and torque limiting mechanism work together to effectively reduce the impact of instantaneous high temperatures above 600°C generated during tapping on tool life. The overload protection module achieves dynamic torque compensation through a disc spring group. When the cutting resistance exceeds the set threshold, it can automatically release to avoid the scrapping of the workpiece caused by the tap breakage.

In the dimension of industrial application, this type of product has formed a differentiated solution system: the chuck with a dual-channel cooling design is used in the automotive manufacturing field, and the internal cooling tool holder can achieve direct delivery of the cutting fluid to the processing area; the aerospace industry prefers chucks with radial floating compensation function, which can automatically correct the position error within 0.05mm caused by the workpiece clamping deviation. It is worth noting that the intelligent chuck is gradually entering the industrialization stage. The model with integrated strain sensor can feedback the cutting force data in real time and realize the dynamic optimization of processing parameters through the industrial Internet of Things platform.

In terms of standard adaptability, mainstream products are marked with ISO529 and DIN179A dual certifications to ensure that they meet the local machine tool interface specifications when exported to the European and American markets. The specially designed Morse taper interface can adapt to MT2-MT5 drilling and milling equipment. This cross-platform compatibility gives it a significant advantage in mold repair workshops. With the growing demand for composite material processing, the new generation of chucks has begun to use a carbon fiber reinforced matrix, which reduces weight by 40% while maintaining the same rigidity. It is particularly suitable for rapid tool change scenarios in robotic automated production lines.