Cross-Hole Deburring Blade Tungsten Carbide Dual-Angle Tool for Automotive Parts

I. Product Description

1. Material and Process

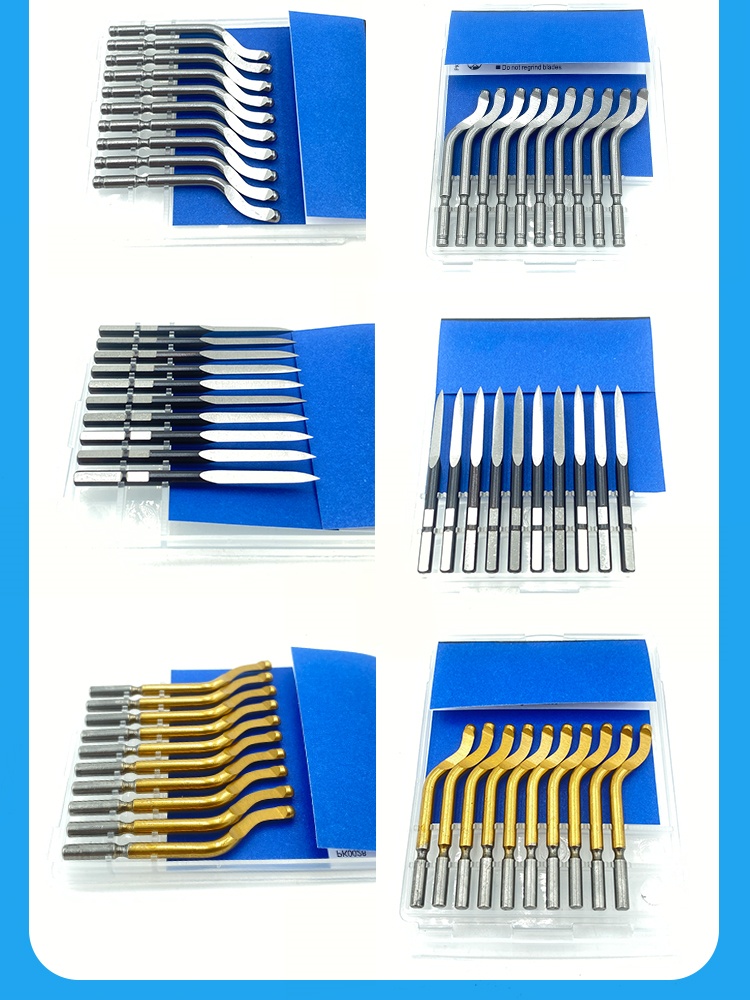

- Made of M2 high-speed steel or tungsten steel, with a hardness of 63RC, some models are titanium-plated on the surface to significantly improve wear resistance.

- The blade design covers a variety of inclination angles such as 40°, 45°, and 60°, which are suitable for chamfering requirements of different apertures; the accuracy is up to 0.1mm, supporting the fine processing of complex scenes such as cross holes and deep holes.

2. Functional characteristics

- Double-sided deburring: burrs on the front and back of the hole can be processed at the same time in one operation to avoid repeated processing.

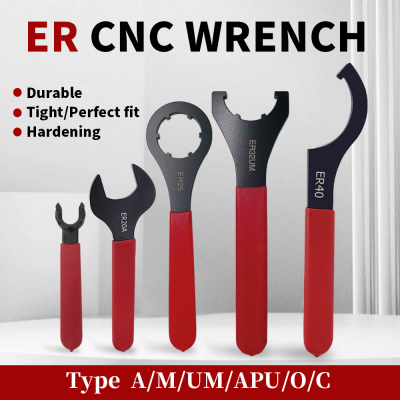

- Modular design: supports rapid replacement of blades, and is suitable for a variety of equipment such as pneumatic drills, electric drills, and CNC machine tools.

- Safety protection: Some models are equipped with anti-slip handles and safety locks to reduce operating risks.

3. Applicable objects

- Mainly used for cleaning burrs on the holes and edges of metals (stainless steel, alloy steel, aluminum) and plastic materials, especially good at processing cross holes, deep holes and other areas that are difficult to reach with traditional tools.

2. Industry application scenarios

1. Automobile manufacturing

- Clean the burrs of key components such as engine cylinders, gear holes of transmissions, cross holes of hydraulic valve bodies, etc. to ensure assembly accuracy and fluid sealing.

2. Aerospace

- Used for precision deburring of high-strength alloy materials such as aircraft landing gears and turbine blade cooling holes to avoid fatigue fracture caused by stress concentration.

3. Electronic equipment manufacturing

- Remove edge burrs of small parts such as precision connectors and heat sinks to prevent circuit short circuits or reduced heat dissipation performance.

4. General machining

- Suitable for batch deburring of industrial parts such as valves, pump bodies, and molds to improve surface finish.

3. Core advantages

1. Efficiency and economy

- Double-sided deburring can be completed in a single operation, which is more than 10 times more efficient than traditional files, significantly reducing labor costs.

2. Industrial-grade durability

- The life of tungsten steel blades can reach 3-5 times that of ordinary tool steel, and it supports multiple grinding and reuse.

3. High-precision adaptability

- By adjusting the blade inclination and pressure, the chamfer depth (±0.05mm) can be accurately controlled to meet high tolerance requirements.

4. Convenient operation

- No complex programming or equipment modification is required, manual tools can complete the operation, suitable for rapid deployment of production lines.

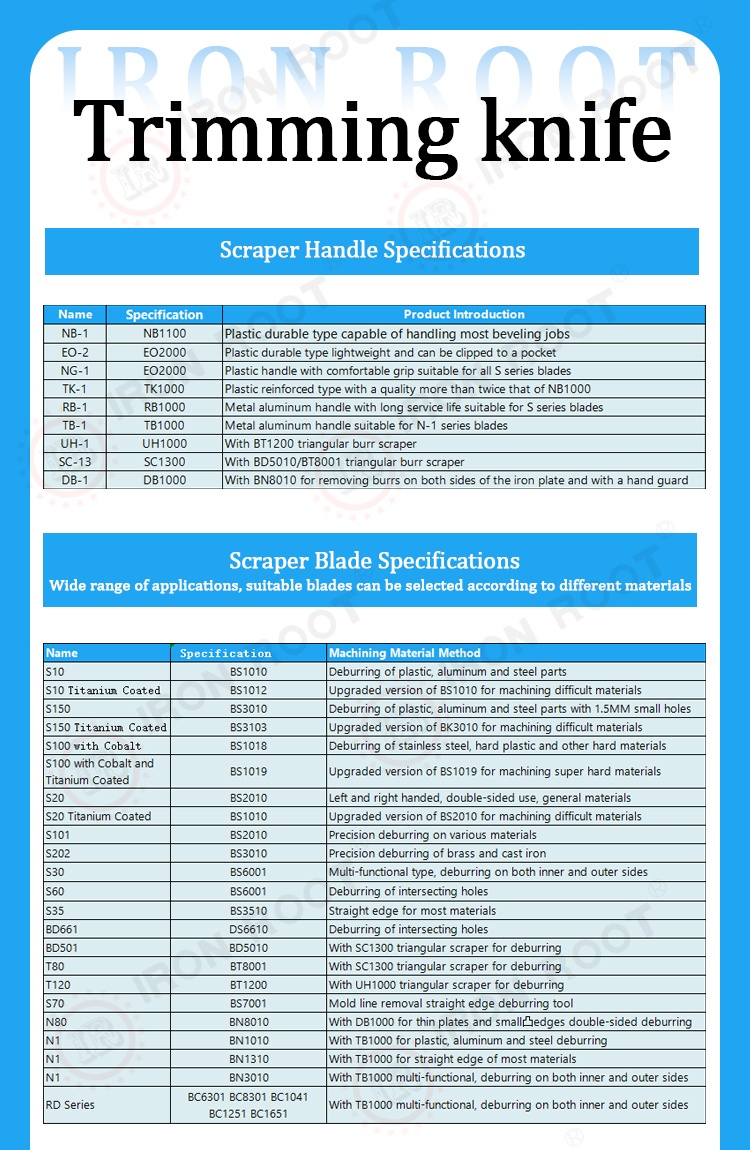

| Name | Specification | Machining Material Method |

| S10 | BS1010 | Deburring of plastic, aluminum and steel parts |

| S10 Titanium Coated | BS1012 | Upgraded version of BS1010 for machining difficult materials |

| S150 | BS3010 | Deburring of plastic, aluminum and steel parts with 1.5MM small holes |

| S150 Titanium Coated | BS3103 | Upgraded version of BK3010 for machining difficult materials |

| S100 with Cobalt | BS1018 | Deburring of stainless steel, hard plastic and other hard materials |

| S100 with Cobalt and Titanium Coated | BS1019 | Upgraded version of BS1019 for machining super hard materials |

| S20 | BS2010 | Left and right handed, double-sided use, general materials |

| S20 Titanium Coated | BS1010 | Upgraded version of BS2010 for machining difficult materials |

| S101 | BS2010 | Precision deburring on various materials |

| S202 | BS3010 | Precision deburring of brass and cast iron |

| S30 | BS6001 | Multi-functional type, deburring on both inner and outer sides |

| S60 | BS6001 | Deburring of intersecting holes |

| S35 | BS3510 | Straight edge for most materials |

| BD661 | DS6610 | Deburring of intersecting holes |

| BD501 | BD5010 | With SC1300 triangular scraper for deburring |

| T80 | BT8001 | With SC1300 triangular scraper for deburring |

| T120 | BT1200 | With UH1000 triangular scraper for deburring |

| S70 | BS7001 | Mold line removal straight edge deburring tool |

| N80 | BN8010 | With DB1000 for thin plates and small凸edges double-sided deburring |

| N1 | BN1010 | With TB1000 for plastic, aluminum and steel deburring |

| N1 | BN1310 | With TB1000 for straight edge of most materials |

| N1 | BN3010 | With TB1000 multi-functional, deburring on both inner and outer sides |

| RD Series | BC6301 BC8301 BC1041 BC1251 BC1651 | With TB1000 multi-functional, deburring on both inner and outer sides |

| Name | Specification | Product Introduction |

| NB-1 | NB1100 | Plastic durable type capable of handling most beveling jobs |

| EO-2 | EO2000 | Plastic durable type lightweight and can be clipped to a pocket |

| NG-1 | EO2000 | Plastic handle with comfortable grip suitable for all S series blades |

| TK-1 | TK1000 | Plastic reinforced type with a quality more than twice that of NB1000 |

| RB-1 | RB1000 | Metal aluminum handle with long service life suitable for S series blades |

| TB-1 | TB1000 | Metal aluminum handle suitable for N-1 series blades |

| UH-1 | UH1000 | With BT1200 triangular burr scraper |

| SC-13 | SC1300 | With BD5010/BT8001 triangular burr scraper |

| DB-1 | DB1000 | With BN8010 for removing burrs on both sides of the iron plate and with a hand guard |