75-Degree Holders: A Hit With Machinists

75-Degree Screw-Type Tool Holders: Machinists Share Why This New Line Is a "Game-Changer"

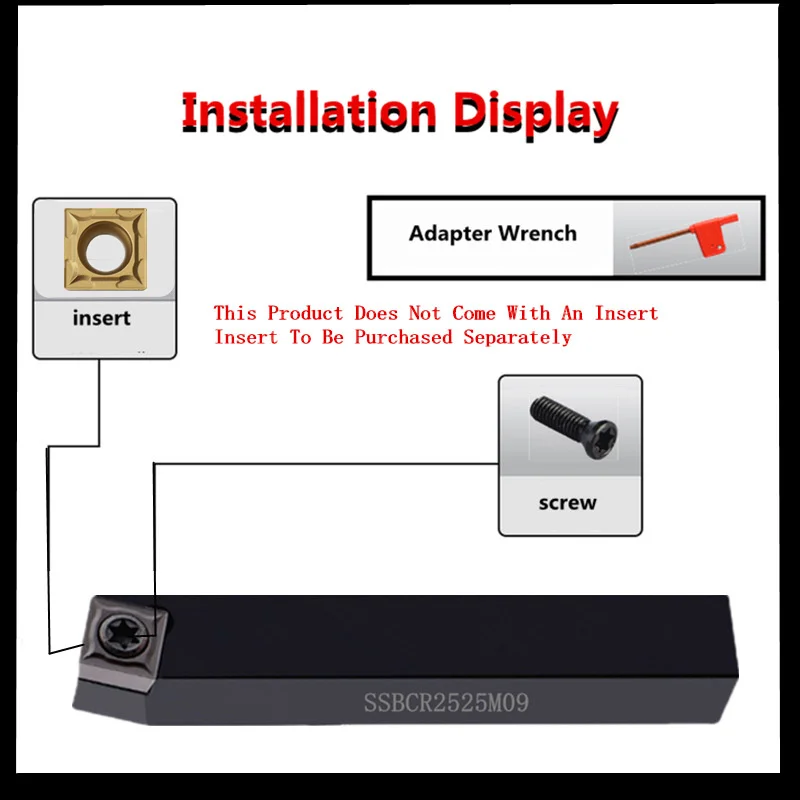

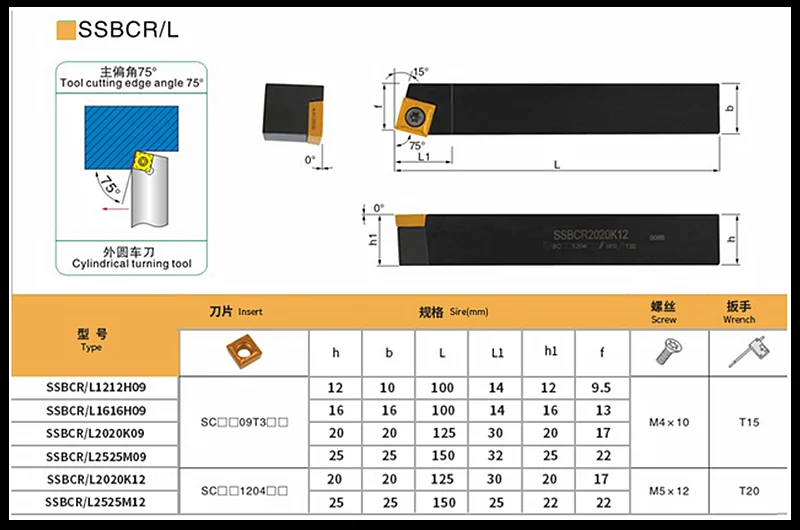

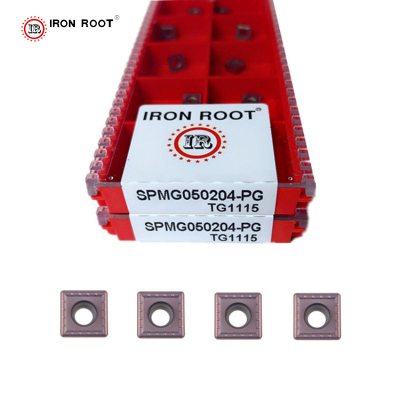

The metalworking world is abuzz with a new arrival: the 75-degree screw-type external cutting tool holders, including models like SSBCR1212H09, SSBCR2525M09, and SSBCL2525M12. But don’t just take manufacturers’ word for their impact—ask the machinists who’ve swapped their old tooling for these rugged workhorses.

“Let me put it this way: I used to dread roughing 4140 steel,” says Maria Gonzalez, a CNC operator at a mid-sized automotive parts shop. “My old tool holder would vibrate so bad, the part finish looked like a cheese grater, and I’d swap inserts every 50 parts. Now? This 75-degree holder clamps the insert so tight, it’s like it’s welded on. No vibration, no chattering. I ran 200 parts yesterday, and the insert still looks brand new. The finish? Smooth enough to pass our QA’s ‘fingernail test’—no scratches, no waves. It’s wild.”

For small-shop owner Raj Patel, the difference lies in versatility. “I handle everything from aluminum brackets to hardened steel shafts, so swapping tooling used to eat up an hour a day. These holders? The screw-type clamp makes changing inserts a 30-second job—no fumbling with tiny bolts or alignment. And that 75-degree angle? It’s a hero for tight spots. Last week, I had to turn a 2mm shoulder on a 10mm shaft—my old 90-degree holder kept nicking the edge, but this one glided right in. Saved me from scrapping $200 worth of material.”

Durability is another win, according to James Wilson, a veteran machinist at an aerospace component manufacturer. “We push tools to the limit—high speeds, heavy feeds, Inconel and titanium. My first thought with these was, ‘They’ll bend like the rest.’ Wrong. I’ve been running the SSBCR2020K12 on a 12-hour shift, day in and day out, for three weeks. The square shank (20×20mm) hasn’t warped a micron, and the screw clamp? Still tight as the day I installed it. My supervisor thought I was exaggerating—until he checked the tool offsets. Zero drift. Zero.”