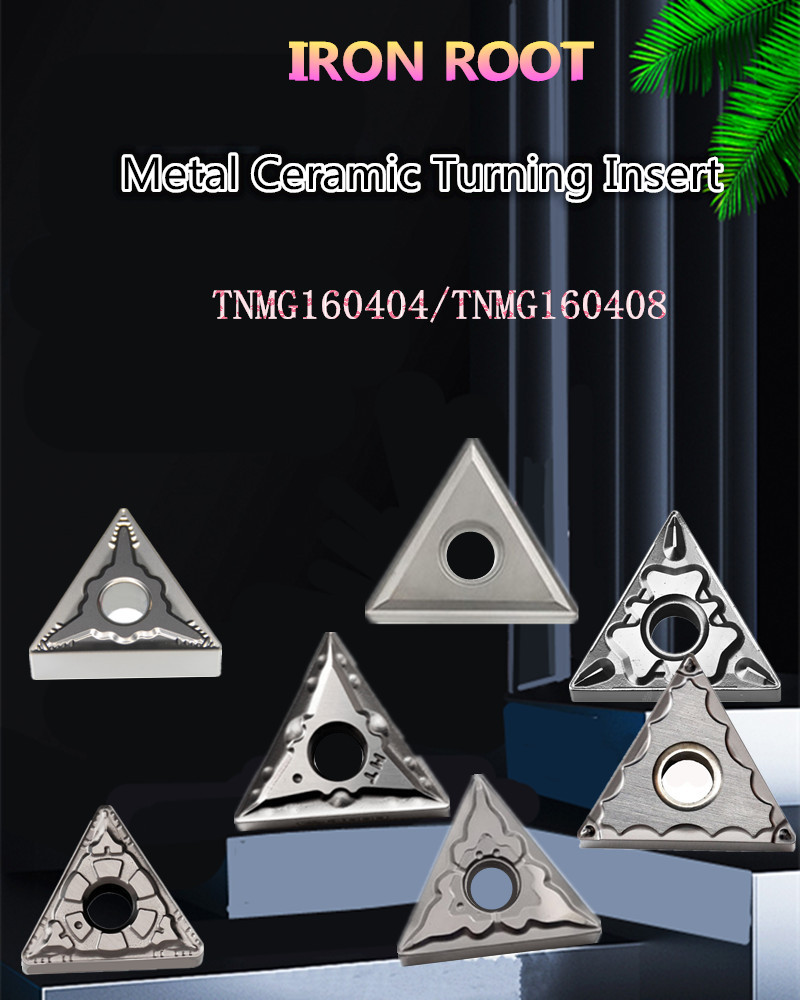

TNMG 1604 Carbide Ceramic Inserts

TNMG 1604 insert carbide ceramic inserts have the following advantages:

Negative rake angle design provides good chip control and high edge strength.

Suitable for medium to rough machining, suitable for machining of a variety of steels.

There are a variety of coatings and material options, such as YBC351, which provides high wear resistance

and impact resistance.

Standardized size, easy to install and replace.

Usually sold in packages of 10 pieces, economical and practical.

About the product

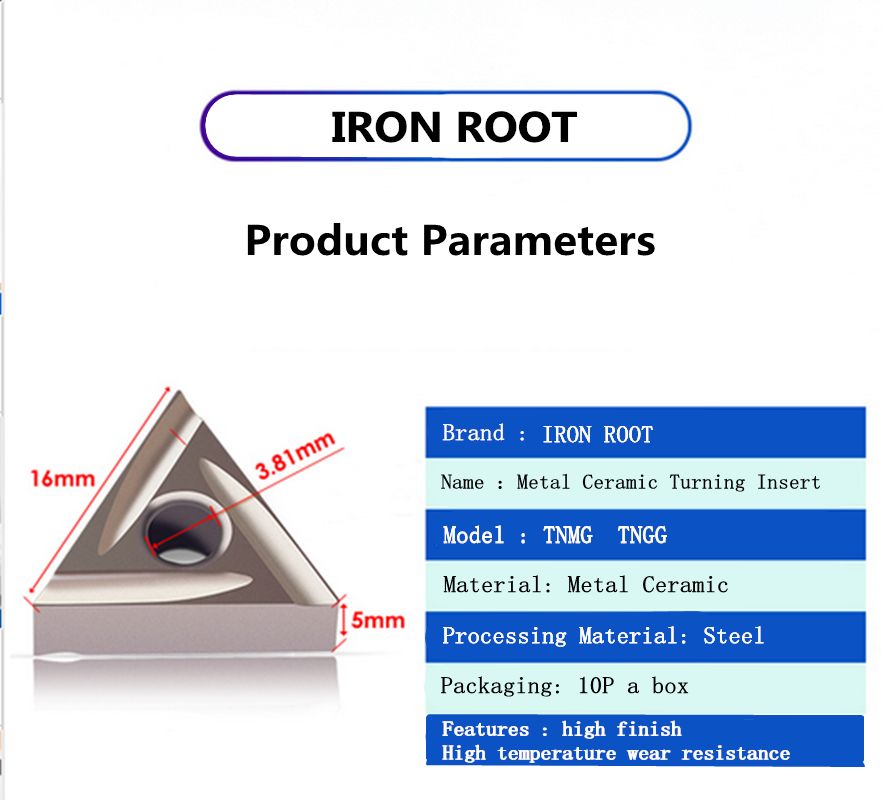

The TNMG1604 Ceramic cutting inserts ceramic insert is a triangular, negative rake angle insert designed for efficient cutting. With an internal inscribed circle (IC) of 0.5 inches (12.7mm), a thickness of 0.188 inches (3/16 inches), and a nose radius of 0.0625 inches (1/16 inches), this insert is suitable for general-purpose work. The 60° included angle of the TNMG432 insert makes it ideal for versatile turning operations, while its negative rake angle design provides a durable cutting edge that is ideal for hard materials and intermittent cutting. In addition, the TNMG432 insert is often coated with materials such as TiN, TiCN, AlTiN, etc. to extend tool life and improve wear resistance. This insert performs well in roughing, semi-finishing, and finishing, and is particularly suitable for steel, cast iron, and some harder materials.

Material & Coating

The TNMG1604 Best carbide inserts is constructed from high-performance carbide ceramic, blending a tungsten carbide substrate with ceramic reinforcements (e.g., titanium carbide or aluminum oxide) and a cobalt binder (6–8% content). This composition delivers exceptional hardness (92–94 HRA) and wear resistance, critical for machining hard materials. Most variants feature advanced coatings: - **TiN (Titanium Nitride)**: Enhances surface hardness and reduces friction, ideal for general-purpose steel machining. - **TiCN (Titanium Carbonitride)**: Improves wear resistance in medium-load operations, suitable for cast iron. - **AlTiN (Aluminum Titanium Nitride)**: Provides high-temperature stability (up to 900°C) and oxidation resistance, optimizing performance in stainless steel and hard alloy machining.

Key Features & Geometry

Applications

Compatible Machines

Lifespan & Performance

| use | Model | ØI.C | T | Ød | Re | |

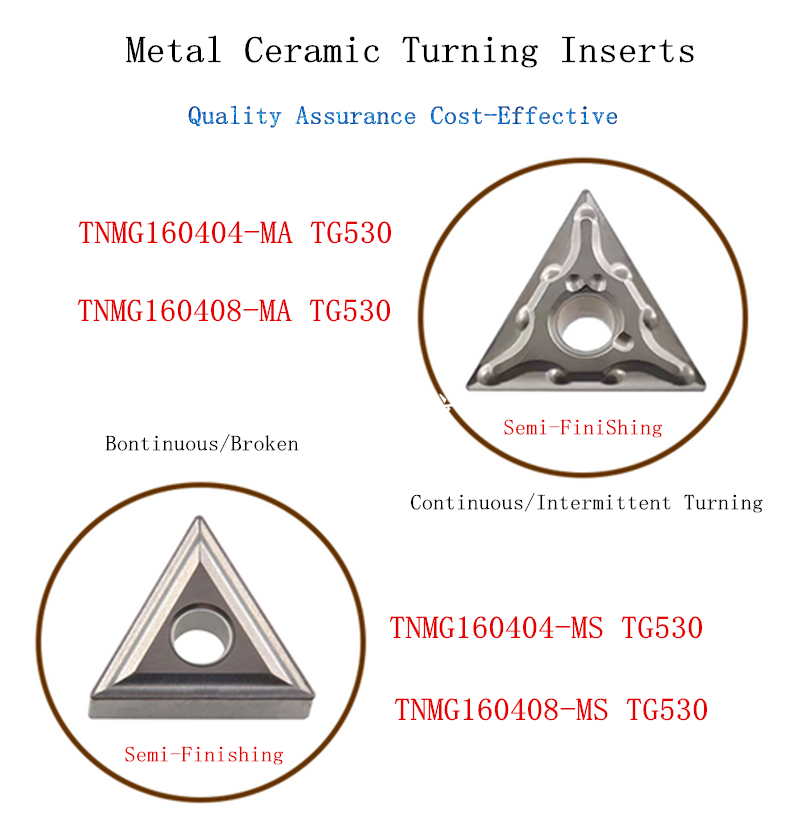

| Semi-finishing | TNMG160402-HA | 9.525 | 4.76 | 3.81 | 0.2 | |

| TNMG160404-HA | 9.525 | 4.76 | 3.81 | 0.4 | ||

| TNMG160408-HA | 9.525 | 4.76 | 3.81 | 0.8 | ||

Semi-finishing - Roughing | TNMG160402-R-S | 9.525 | 4.76 | 3.81 | 0.2 | |

| TNMG160404-R-S | 9.525 | 4.76 | 3.81 | 0.4 | ||

| TNMG160408-R-S | 9.525 | 4.76 | 3.81 | 0.8 | ||

| Finishing semi-finishing | TNMG160404-HQ | 9.525 | 4.76 | 3.81 | 0.4 | |

| TNMG160408-HQ | 9.525 | 4.76 | 3.81 | 0.8 | ||

| Roughing | TNMG160404-R-VF | 9.525 | 4.76 | 3.81 | 0.4 | |

| TNMG160408-R-VF | 9.525 | 4.76 | 3.81 | 0.8 | ||

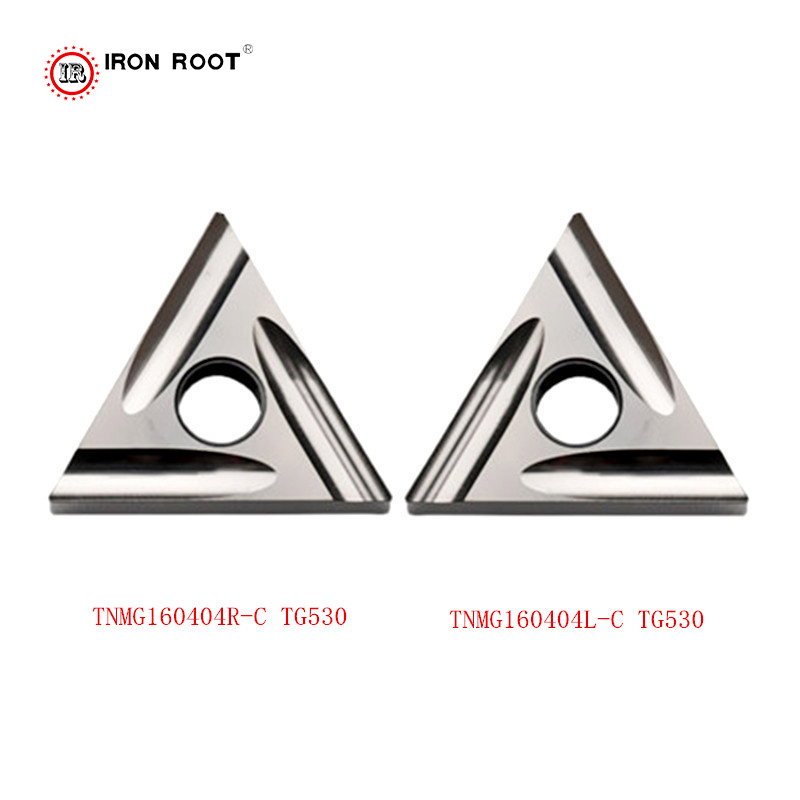

| Roughing | TNMG160404-L-VF | 9.525 | 4.76 | 3.81 | 0.4 | |

| TNMG160408-L-VF | 9.525 | 4.76 | 3.81 | 0.8 | ||

| MediumCutting | TNMG160404-MT | 9.525 | 4.76 | 3.81 | 0.4 | |

| TNMG160408-MT | 9.525 | 4.76 | 3.81 | 0.8 | ||

| Semi-finishing - Roughing | TNMG160404-R-S | 9.525 | 4.76 | 3.81 | 0.4 | |

| TNMG160408-R-S | 9.525 | 4.76 | 3.81 | 0.8 | ||

| Semi-finishing - Roughing | TNMG160404-L-S | 9.525 | 4.76 | 3.81 | 0.4 | |

| TNMG160408-L-S | 9.525 | 4.76 | 3.81 | 0.8 |

Advantages

About Our Company

Welcome to inquire about the prices, and we will provide you with the best service.