IRON ROOT U-Drills: Drilling Made Easy"

IRON ROOT U-Drills: Drilling Made Easy"

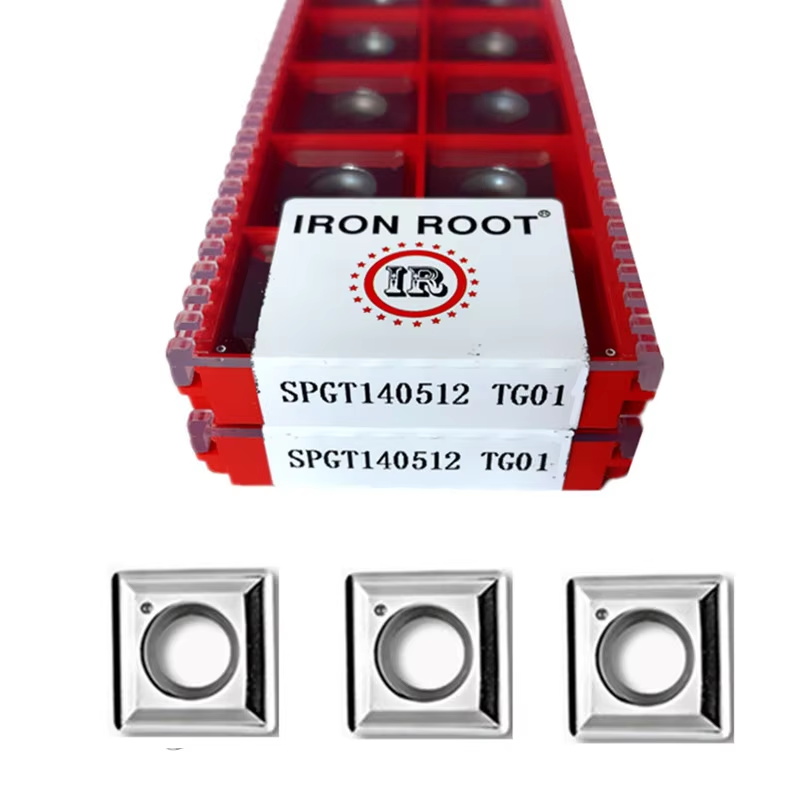

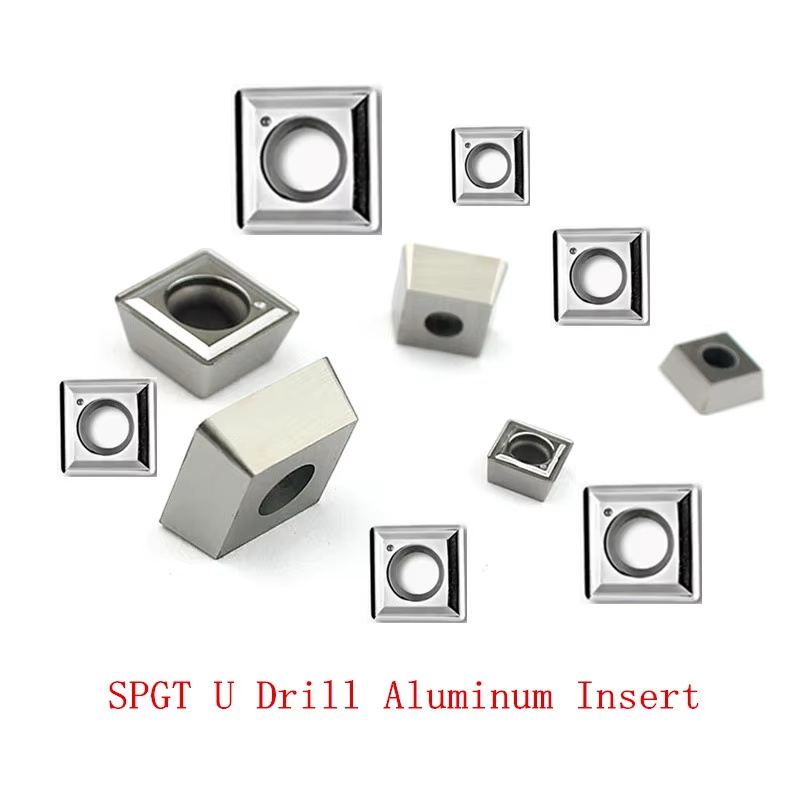

Move over, clunky old drill bits—there’s a new hero in the CNC shop, and it’s got a funny name: the carbide insert U-drill. But ask machinists who’ve traded their worn-out tools for models like IRON ROOT SPGT050204 or IRON ROOT SPGT110408, and they’ll tell you: this “U” stands for “unbelievable.”

“Let me set the scene,” says Jake Larson, a CNC operator at a midwest auto parts plant. “Last month, I was drilling 3mm holes in 4140 steel with my old drill. It sounded like a cat being squeezed, the chips balled up into metal tumbleweeds, and I broke three bits in a day. Then the boss dropped off these SPGT060204 inserts. First try? It cut through that steel like it was room-temperature butter. No squealing, no drama—just tiny, curly chips that fell right into the pan. I drilled 500 holes before even thinking about swapping the insert. 500! I texted my buddy in the next bay: ‘Why didn’t anyone tell me drills could enjoy their job?’”

For Lisa Chen, who runs a small machine shop in Texas, the magic is in the “set it and forget it” factor. “I used to baby my drills—tiptoeing on speed, checking every 10 holes. These U-drills? I loaded up the IRON ROOT SPGT090408 insert, hit ‘go,’ and walked away to make coffee. Came back 20 minutes later, and the holes were so straight, my calipers thought I was cheating. The best part? When the edge wore, I just spun the insert like a tiny roulette wheel—boom, fresh edge. No fumbling with tools, no re-centering. It’s like the drill grew a brain.”

So what makes them click? The carbide’s tough enough to outlast steel, the indexable design cuts down on tool swaps, and the chip breakers? They turn messy shavings into “drill confetti,” as Larson puts it. Plus, with sizes from the tiny SPGT050204 to the beefy IRON ROOT SPGT110408, there’s a fit for every job.