How to choose the right tool?

How to choose the right tool? In the field of mechanical processing, the correct selection of tools is crucial to improving processing efficiency, ensuring processing quality and reducing production costs. 1. Clarify the processing requirements Processing type: Determine whether it is turning, milling, drilling or grinding. Different processing types have different requirements for the shape, edge angle and cutting parameters of the tool. Workpiece material: Understand the hardness, toughness, heat treatment state and other characteristics of the workpiece material. For example, when processing high-hardness materials, it is necessary to select tool materials with high hardness and good wear resistance. Processing accuracy: Select the appropriate tool according to the processing accuracy requirements. High-precision processing requires the use of high-precision and high-rigidity tools, such as precision boring tools, ball-end milling cutters, etc.

2. Choose the right tool type

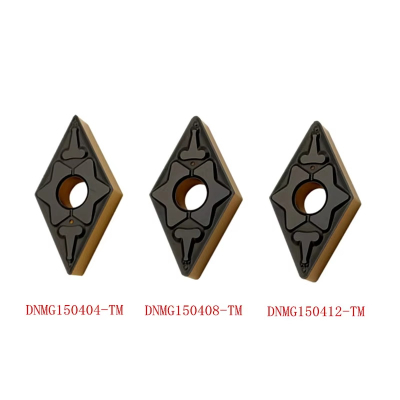

Turning: Select the turning tool according to the processing part (external circle, inner hole, end face, etc.) and processing requirements. For example, a turning tool with a 90° main deflection angle can be used for external turning, and an internal turning tool can be used for internal hole processing.

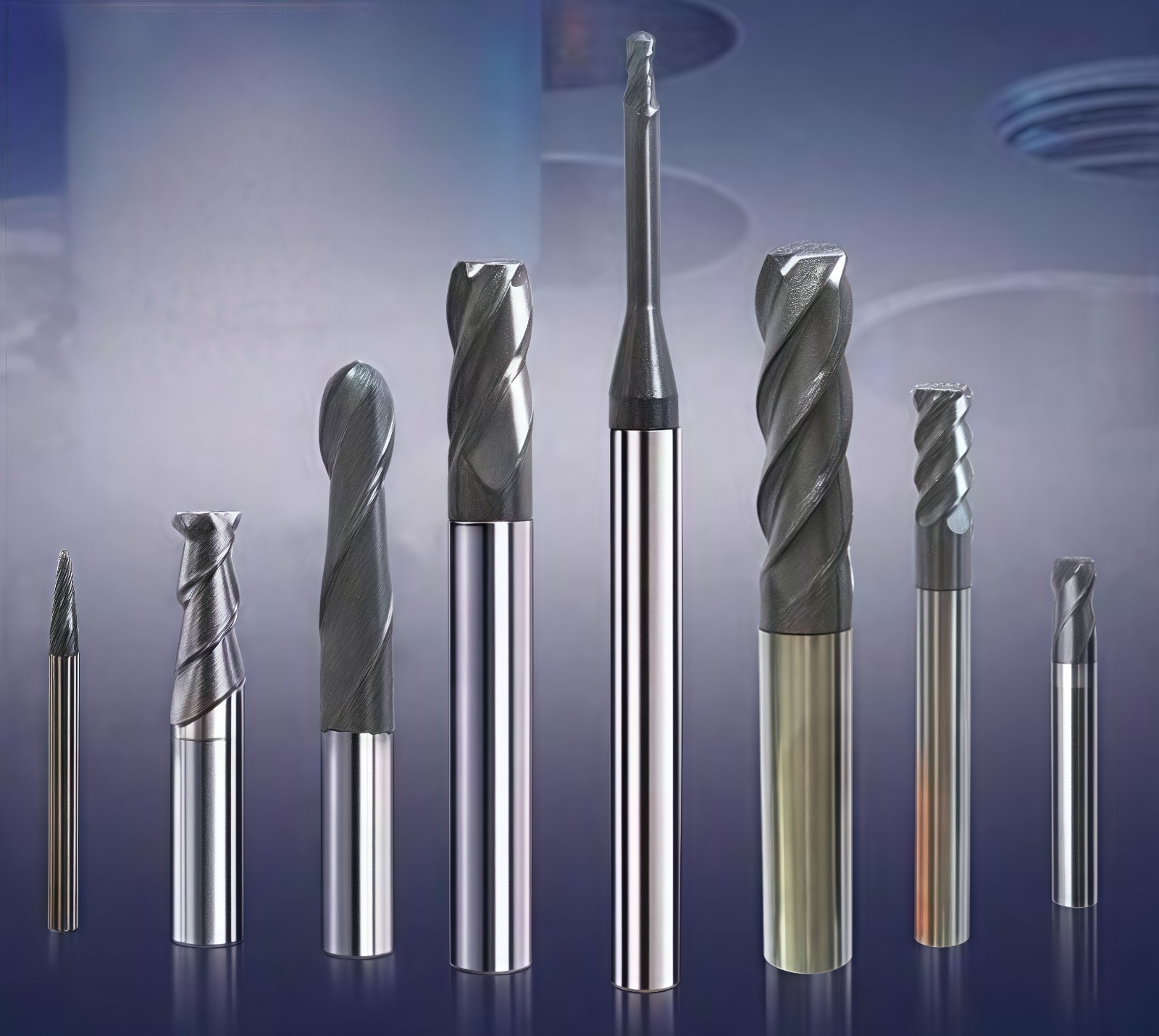

Milling: Select a milling cutter according to the shape and size of the processing surface. End mills or face milling cutters can be used for plane processing, and ball head milling cutters or ring milling cutters can be used for three-dimensional curved surface processing.

Drilling: Select a drill bit according to the diameter and depth of the hole. Twist drills can be used for small hole processing, and gun drills or deep hole drills can be used for deep hole processing.

3. Evaluate tool performance

Tool material: Select tool materials suitable for processing workpiece materials, such as high-speed steel, cemented carbide, ceramics, etc. High-speed steel tools are suitable for medium and low speed cutting, cemented carbide tools are suitable for high-speed cutting, and ceramic tools are suitable for finishing of high-hardness materials.

Tool geometry: Select appropriate tool geometry according to processing requirements, such as rake angle, back angle, main deflection angle, cutting edge inclination angle, etc. Reasonable geometry can reduce cutting force, reduce cutting heat, and increase tool life.

Tool coating: Select appropriate tool coating, such as TiN, TiAlN, AlTiN, etc. Coating can improve the hardness, wear resistance and heat resistance of the tool and extend the tool life.

Test cutting and optimization of the tool

Test cutting: Test cutting of the tool before formal processing, observe the cutting effect, cutting force, cutting heat, tool wear, etc., and adjust the tool parameters and cutting amount in time.

Optimization: Optimize tool selection and cutting parameters according to the test cutting results, such as adjusting the main deflection angle, cutting edge angle, cutting speed, feed rate, etc. of the tool to achieve the best processing effect.

In short, the correct selection of tools is a key technology in mechanical processing. By correctly selecting the best tool, the processing efficiency can be improved, the processing quality can be guaranteed, and the production cost can be reduced. In actual processing, the most suitable tool should be selected based on the specific processing conditions and requirements, taking into account various factors.