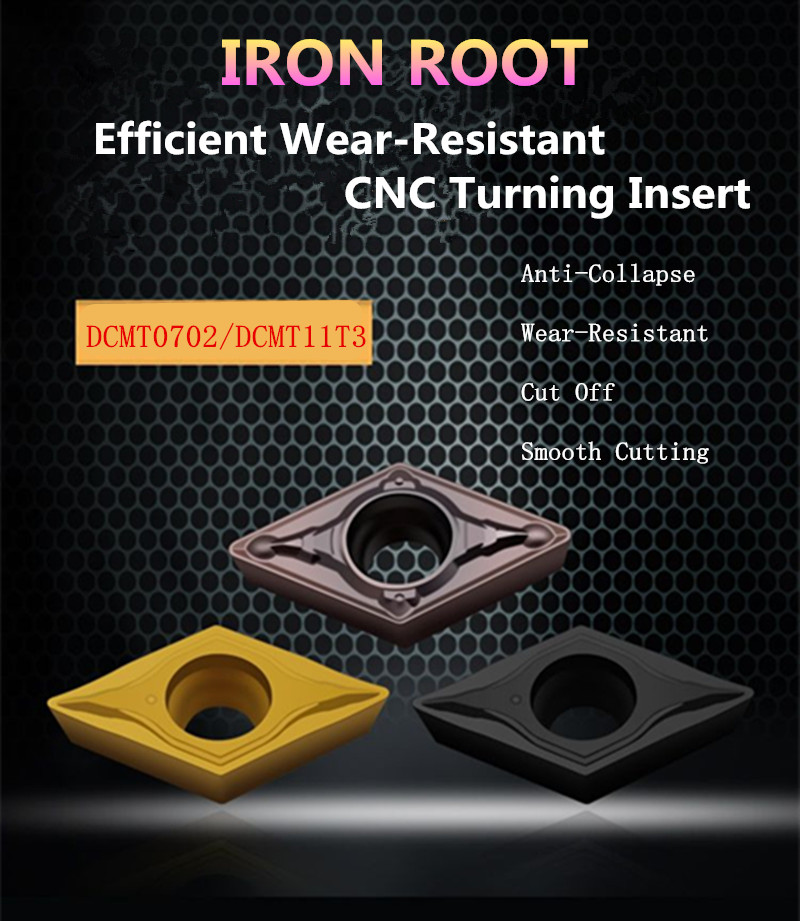

DCMT Indexable Carbide Lathe Tools

DCMT07 turning inserts are designed to improve productivity in stainless steel machining. Here are some of their

key features:

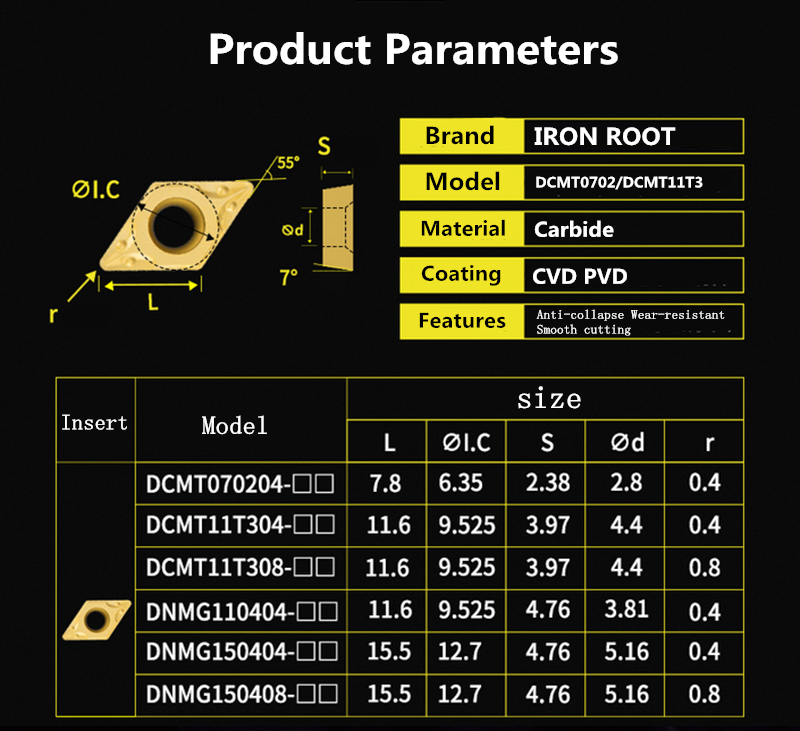

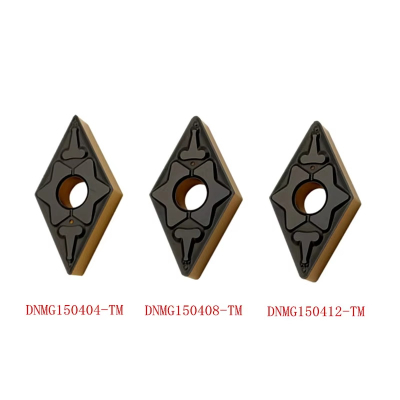

Single-Sided Geometry:CNC turning cutting tools DCMT07 inserts have a single-sided geometry with a 55° diamond shape and a 7° back angle

Cermet Material: These inserts are made of cermet and are suitable for a wide range of materials including stainless

steel.

Indexable: DCMT Indexable Carbide Lathe Tools DCMT07 inserts are indexable and can be rotated to expose a new cutting edge

Versatile Applications: These inserts are versatile and can be used for both roughing and finishing operations

Customizable: They can be customized to meet the specific requirements of different machining operations.

Coating Options: These inserts can be coated with a variety of coatings

About the product

DCMT 3(2.5)1 indexable carbide lathe tools are designed for versatility in metalworking, featuring a 55° rhombic shape with a 7° positive rake angle. These inserts are suitable for a range of materials, including stainless steel and steel alloys. They offer two effective cutting edges and are secured via a cylindrical fixing hole with a countersink on one side. The DCMT 3(2.5)1 size indicates an edge length of 3/8", a thickness of 5/32", and a corner radius of 1/64". These inserts are known for their strong cutting edge and smooth cutting action, suitable for roughing to semi-finishing operations.

Material & Coating

Key Features

Single-Sided 55° Diamond Geometry: The 55° diamond shape with a 7° back angle minimizes cutting forces, making it ideal for precision machining. This design improves access to tight spaces, such as shoulder turning in complex stainless steel components.

Indexable Design:CNC turning cutting tools Featuring multiple cutting edges that can be rotated for repeated use, these inserts maximize tool utilization and reduce replacement frequency, lowering operational costs.

Dual Operation Capability: Engineered for both roughing and finishing operations, they deliver consistent performance across a range of material removal rates—from heavy stock removal to achieving fine surface finishes (Ra ≤ 0.8μm).

Customizable Options: Carbide blades Available with tailored chipbreakers, edge preparations, and coating thicknesses to meet specific machining needs, such as high-speed finishing or heavy-duty roughing of stainless steel alloys.

Applications

Optimized for stainless steel machining, DCMT07 inserts excel in:

Automotive & Aerospace: Turning stainless steel components like exhaust manifolds, turbine parts, and hydraulic fittings.

Medical Equipment: Machining precision parts from corrosion-resistant stainless steel (e.g., 316L) with strict surface finish requirements.

General Engineering: Processing stainless steel shafts, valves, and flanges, as well as other materials like alloy steel and cast iron.

Compatible Machines

These inserts are designed for use with:

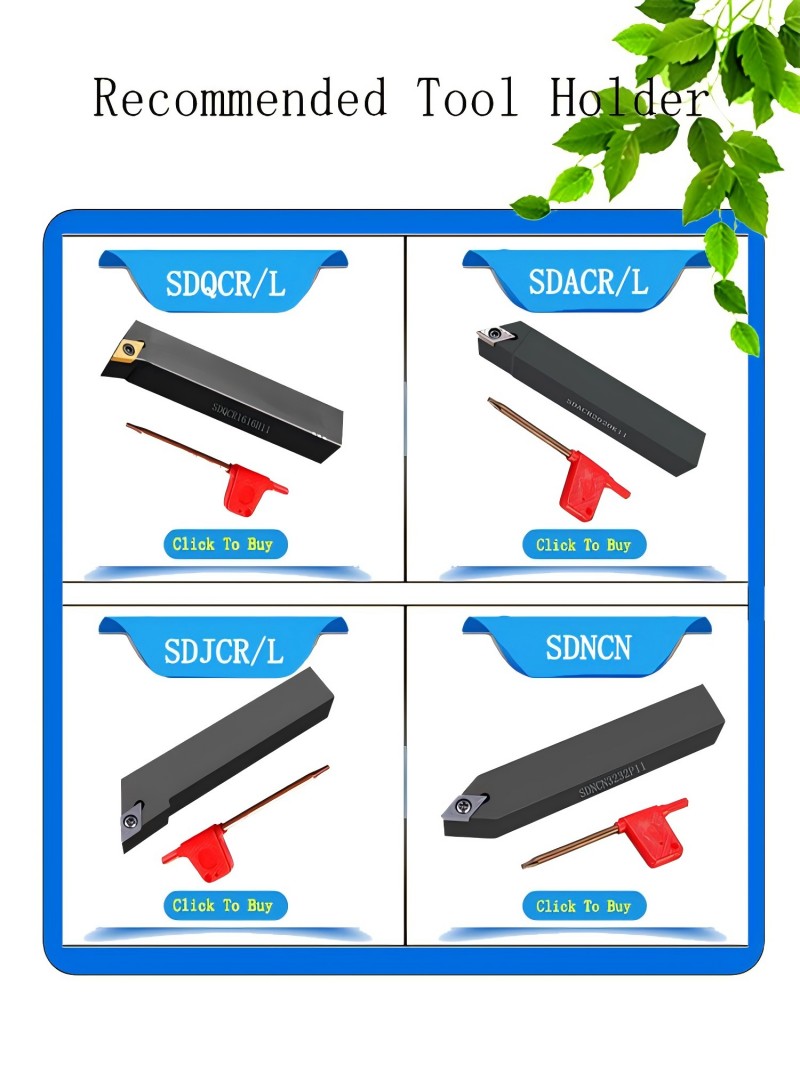

CNC lathes Indexable blades (e.g., Mazak Quick Turn, Haas ST-series) equipped with corresponding tool holders (e.g., SCLCR, SCLPR for external turning; PCLNR for internal turning).

Swiss-type lathes (e.g., Tsugami, Star) for small-diameter stainless steel parts requiring high precision.

Manual lathes with tool post setups, supporting both external and light internal turning operations.

Lifespan

Under recommended parameters (cutting speed: 100–180 m/min for stainless steel; feed rate: 0.1–0.2 mm/rev), each cutting edge provides:

30–45 minutes of continuous finishing operations on stainless steel.

20–30 minutes of roughing operations, depending on material hardness and depth of cut.

The cermet material, combined with wear-resistant coatings, ensures consistent performance across multiple indexings, with total insert lifespan extending to 120–180 minutes of active use before replacement.

CNC Lathes: Fully compatible with modern CNC lathes from leading manufacturers, including Fanuc-controlled models (e.g., Fanuc 0i-TF series), Siemens Sinumerik-equipped lathes (e.g., Siemens 828D), and Haas lathes (e.g., Haas TL-15). These machines leverage the inserts’ precision for automated grooving tasks, such as programmable slotting in batch production.

Slant-Bed CNC Lathes: Optimized for use with slant-bed designs (e.g., Doosan Lynx 2100, Okuma LB3000), which offer enhanced rigidity. The inserts’ shock-resistant performance pairs well with the high stability of these machines, making them ideal for heavy-load grooving in steel and stainless steel.

Manual Lathes: Suitable for traditional manual lathes with grooving attachments (e.g., Clausing-Colchester, South Bend lathes). Their clear laser-marked toolholders simplify setup, allowing operators to quickly align inserts for consistent external and internal grooving.

Swiss-Type Lathes: Adaptable to Swiss-style turning centers (e.g., Tsugami B0326, Star SR-20J) for micro-grooving applications. The inserts’ compact design and precise edge control support small-diameter grooving (≤10mm) in intricate components like medical hardware or watch parts.

Multi-Axis Turning Centers: Compatible with multi-axis machines (e.g., Mazak Integrex i-200S) that combine turning and milling capabilities. They excel in complex operations requiring synchronized grooving and contouring, leveraging their reliable chip evacuation to maintain workflow efficiency.

All compatible machines benefit from the inserts’ compatibility with MGEHR/L, MGEVR/L, MGIVR/L, MGFVR/L, and SMGB toolholders, ensuring a secure fit and minimal runout during high-speed grooving.

About Our Company

Jinan Xinxin Trading Co., Ltd. is a company specializing in a full range of turning tools, milling tools, holemaking tools, carbide cutting tools, machine tool accessories and

other products. At the same time, we accept non-standard product customization and provide perfect tooling solutions for the machining and manufacturing industry.

After years of development, our company firmly believe in the concept of integrity-based, with high-quality service so that the company's products are exported to

Europe, the Middle East, South America, Southeast Asia throughout the world's more than 40 industrialized countries and regions, won the majority of domestic

and foreign customers to support and trust.

Jinan Xinxin Trading Co., Ltd. was founded in 2012, is an excellent comprehensive imported CNC cutting tools agents in Shandong, the company firmly believe in

the concept of good faith, with high quality and attentive service. The company believes in the concept of good faith, with high quality and attentive service. For

the various machining enterprises to supply the world's famous brands of imported CNC cutting tools, machining center tools.

Company Brands

Our company brand IRONROOT series products, with excellent quality and perfect service, strive to reduce the cost of using tools for you.

Main products

Our company, as an important link in the machining field, is following and driving its whole system to run. Our distribution of products has become increasingly systematized, mainly including: Sandvik Coromant sandvikcoromant, Seco, Walter, Kennametal Group Kennametal, Mitsubishi MITSUBISHI, Sumitomo Sumitomo, Kyocera Sholette Kyocera CERATIP, Toshiba, Daijie, Hitachi Tools HITACHI TOOL, ISCAR ISCAR, German cobalt collar Guehring, TEGUTEC TAEGUTEC, KORLOY KORLOY and so on.

Domestic brands: Zhuzhou Diamond Brand, Zigong Great Wall Brand, Zhuzhou Jingcheng Brand, Chengdu Yingge, Ha Yigong, Harbin Tool Factory, Southwest Tools, Chengqi Tools, Shaanxi Cemented Carbide, Zhuzhou Cemented Carbide, Guizhou Yihai, Shanghai Tool Factory and a series of domestic and foreign well-known brands of manufacturers of various types and specifications of CNC blades, Metal lathe tools CNC cutting tools, whole tools, machine-clamped blades, welded blades, toolposts, shank, holder, tungsten steel slats, bars. Tungsten steel slats and bars.

At present, our company's product range includes turning tools, milling tools, drilling tools, tooling systems, carbide cutting tools, machine tool accessories and so on.

Our Customer Reviews

Our products are exported to various countries,milling insert including the United States, the United Kingdom, Spain, Italy, Belgium, France, Germany, etc., and are deeply loved and supported by users in these countries. Metal lathe tools

Thank you very much for watching

Welcome to inquire about the prices, and we will provide you with the best service.

Website: https://www.ironrootcnctools.

Whatsapp/Mobile: +86 13969129141

Email: lronroot190@gmail.com