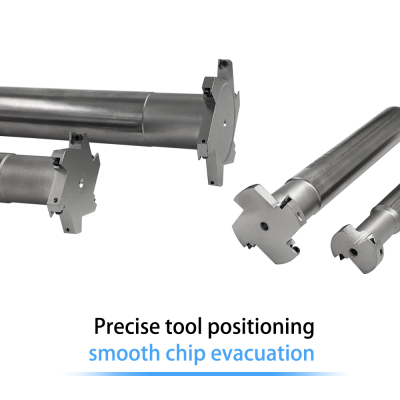

IRON ROOT Launches Next-Generation SP Series U-Drill 2D Precision Meets Power for C20/C25/C32 Applications

IRON ROOT, a global leader in cutting-edge machining solutions, is proud to announce the launch of its SP Series U-Drill 2D (C20/C25/C32), a revolutionary line of indexable carbide drills engineered to redefine efficiency and durability in heavy-duty drilling operations. Designed for high-performance machining across industries, this new series combines advanced geometry, robust materials, and intelligent cooling technology to deliver unmatched precision and cost-effectiveness.

Key Features & Innovations

2D Geometric Design: The SP Series U-Drill 2D incorporates a patented double-edged geometry that optimizes chip evacuation and reduces cutting forces by up to 30%, ensuring smoother operations in tough materials like stainless steel, cast iron, and hardened alloys.

C20/C25/C32 Compatibility: Tailored for diverse applications, the drills support insert sizes C20, C25, and C32, making them ideal for large-diameter drilling (20–32mm) in automotive, aerospace, energy, and general machining sectors.

CoolFlow XT Technology: An integrated internal coolant system maximizes heat dissipation and extends tool life by 40% compared to conventional U-drills, even at elevated feed rates.

Multi-Layer Coating: A proprietary TiAlN/TiSiN hybrid coating enhances wear resistance and thermal stability, enabling consistent performance in high-temperature environments.

Modular Adaptability: Compatible with standard tool holders, the SP Series minimizes setup time and offers seamless integration with CNC machines, lathes, and machining centers.

Industry Applications

Automotive: Drilling crankcases, gearbox housings, and axle components with precision.

Aerospace: High-speed machining of titanium and nickel-based superalloys.

Energy: Efficient drilling in wind turbine hubs and oil/gas valve bodies.

General Machining: Cost-effective solutions for workshops requiring rapid material removal.

Customer Benefits

Reduced Downtime: Faster chip clearance and anti-vibration design lower the risk of tool breakage.

Higher ROI: Extended tool life and replaceable inserts cut operational costs by up to 25%.

Sustainability: Optimized coolant usage aligns with eco-friendly manufacturing practices.