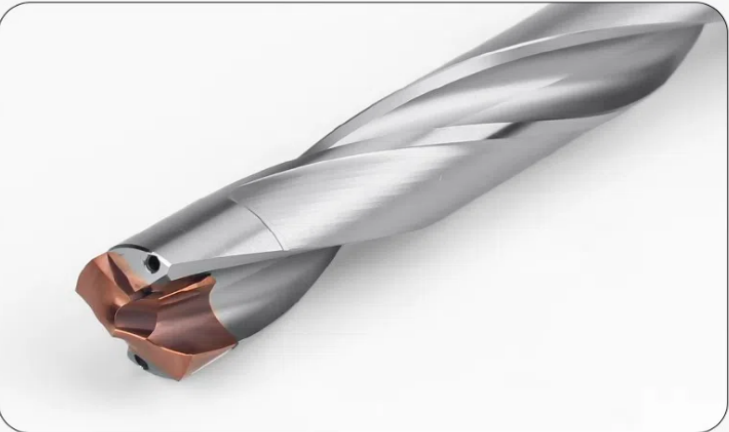

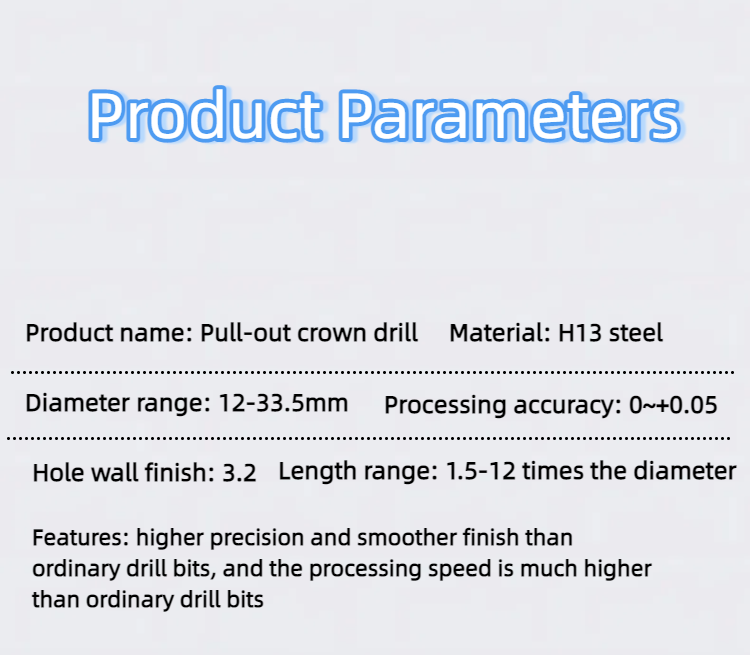

Used as crown drill to replace deep hole drilling tools

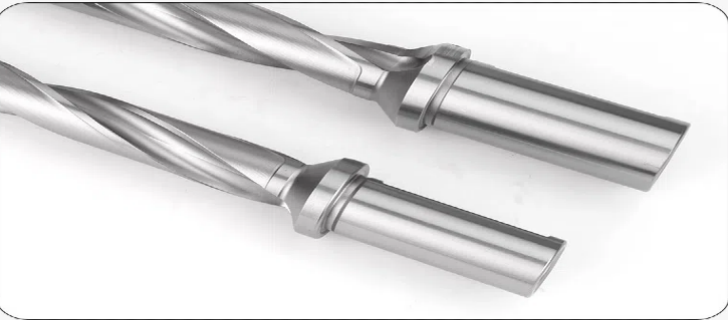

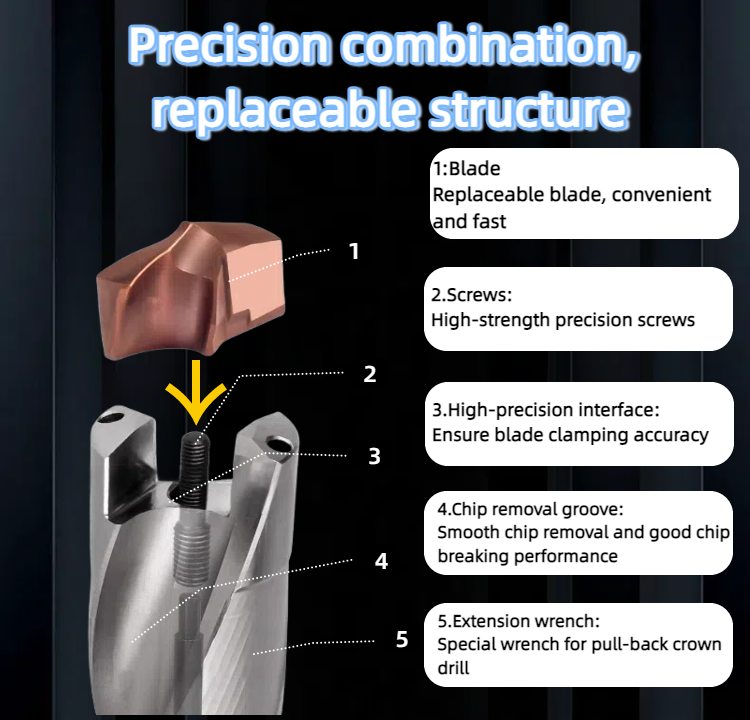

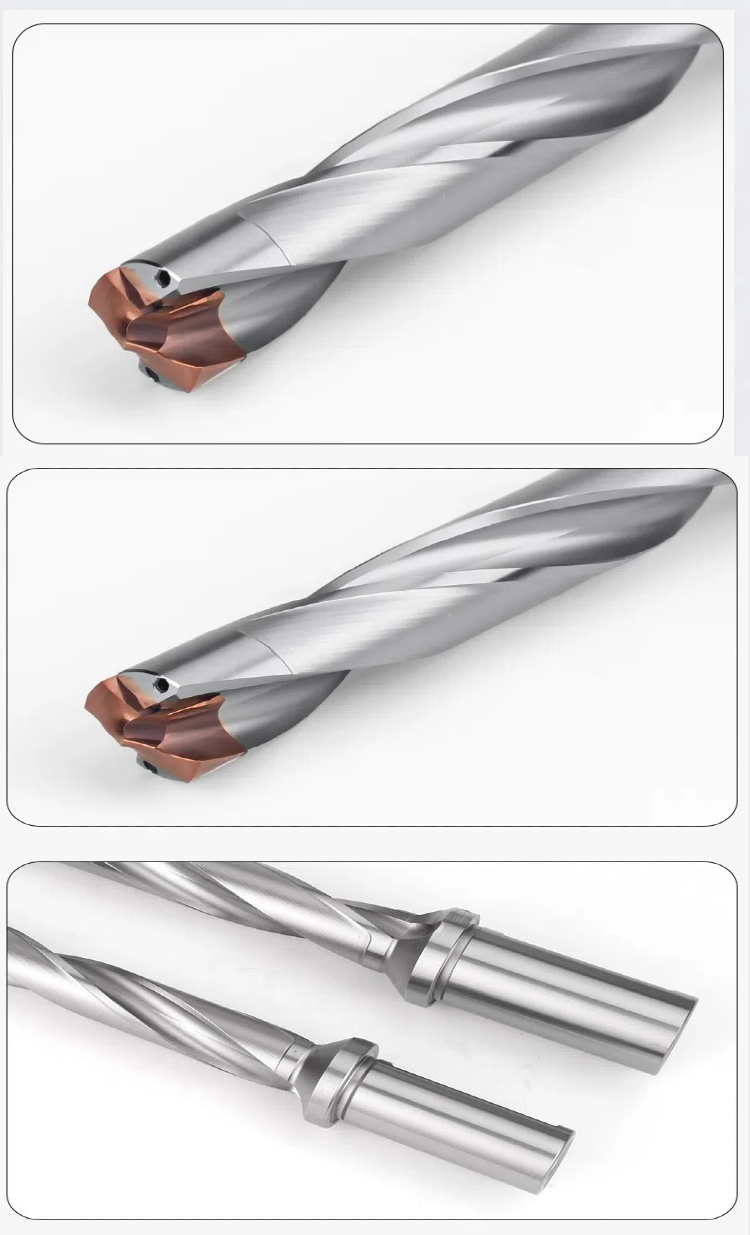

1. Pull-back clamping system

2. Extended U drill structure

II. Processing performance advantages

1. Efficient cutting with violent drilling

Data support:

Cutting speed: Steel processing can reach 200-300m/min (ordinary drill bit 100-150m/min).

Feed rate: 0.3-0.8mm/r, suitable for rough processing of cast iron, single-knife cutting depth can reach 5mm.

Scenario value: In mass production, the processing time of a single piece is shortened by 40%, reducing production costs.

2. High-precision processing capability (High-Precision)

Surface roughness: It can be directly used for semi-finishing, reducing subsequent grinding processes.

III. Cooling and chip removal advantages

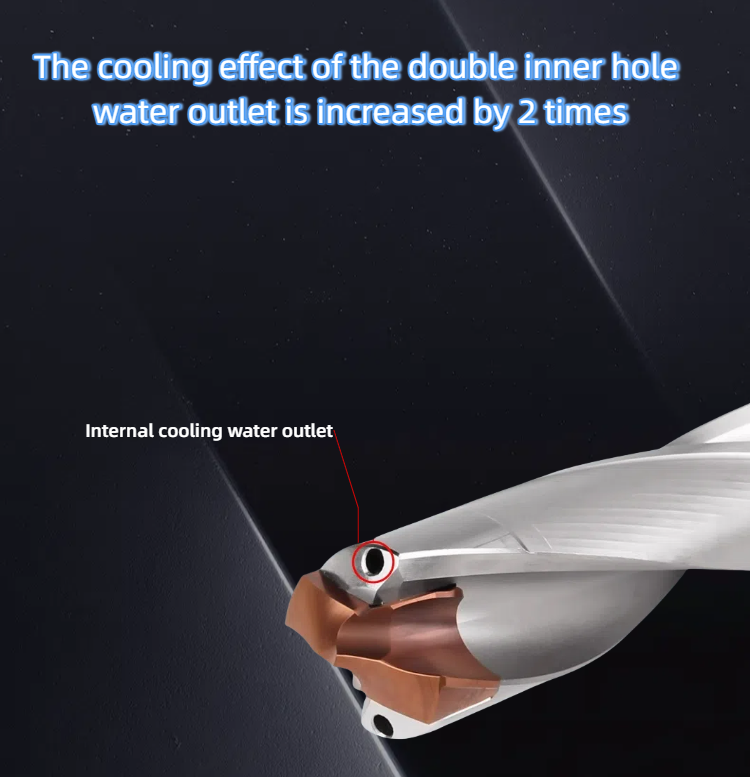

1. Internal cooling system

Technical highlights:

There are 3-4 coolant channels inside the tool bar, and the cooling efficiency of the cutting area is 80% higher than that of the external cooling type, and the tool life is extended by 2-3 times.

Example: When processing 45# steel, the internal cooling design keeps the blade temperature below 300℃ (external cooling can reach 500℃+).

2. Shovel-drill chip removal structure

Chip removal advantages:

The wide spiral groove is combined with internal cooling high-pressure flushing, and the chips are discharged in the form of fragments to avoid long curled chips from wrapping around the tool bar.

Suitable for processing sticky materials such as stainless steel and titanium alloy to reduce chip adhesion.