Shock Resistant CNC Tool Holders – High Precision for Machining

Four core advantages:

1. Significantly improve surface quality and reduce precision errors.

The damping structure actively absorbs high-frequency vibrations generated during the cutting process (such as chatter during milling and boring), preventing surface defects such as tool marks and chatter lines caused by vibration, thereby significantly reducing workpiece surface roughness (e.g., Ra).

2. Extend tool life and reduce consumable costs.

Cutting vibrations subject tool edges to repeated impact loads, leading to chipping and premature wear. Damping toolholders absorb vibration energy, ensuring more even force distribution and reducing impact damage to the cutting edge.

3. Break through processing limitations and improve productivity.

Due to the effects of vibration, conventional toolholders require reduced cutting parameters (such as feed rate and spindle speed) to prevent chatter when machining large aspect ratios (such as deep hole boring and long overhang milling) or high-strength materials (such as titanium alloys and stainless steel). Vibration-damping toolholders can improve cutting parameters (e.g., increase feed speed by 20%-50%) while maintaining stability, thereby shortening single-piece machining time.

4. Reduce equipment wear and protect machine tool spindles.

Long-term cutting vibration not only affects the tool and workpiece, but also transmits to core components such as the machine tool spindle and guideways, accelerating spindle bearing wear and increasing guideway clearance, resulting in reduced equipment accuracy and increased maintenance costs. Vibration-damping toolholders act as "vibration dampers," significantly reducing the vibration energy transmitted to the machine tool, extending the service life of key components such as the spindle and guideways, and reducing equipment maintenance frequency and long-term operating costs.

5. Adaptable to various working conditions and highly versatile.

This series of vibration-damping toolholders typically includes a variety of interface specifications (such as BT, CAT, and HSK, among other mainstream spindle interfaces). They can be used with a variety of tools, including milling cutters, boring tools, and drills, and are suitable for use on various equipment, including vertical machining centers, horizontal milling machines, and boring machines.

Damping Anti-vibrationTool Holder series

Turning tools Boring and milling tools

Product highlights:

1. Turning tool overhang length canreach 16D.

2. Turning tool product diameter

range:8mmsDs300mm.

Turning tool anti-vibration series

One rod with multiple ends, reducingcosts and increasing efficiency!

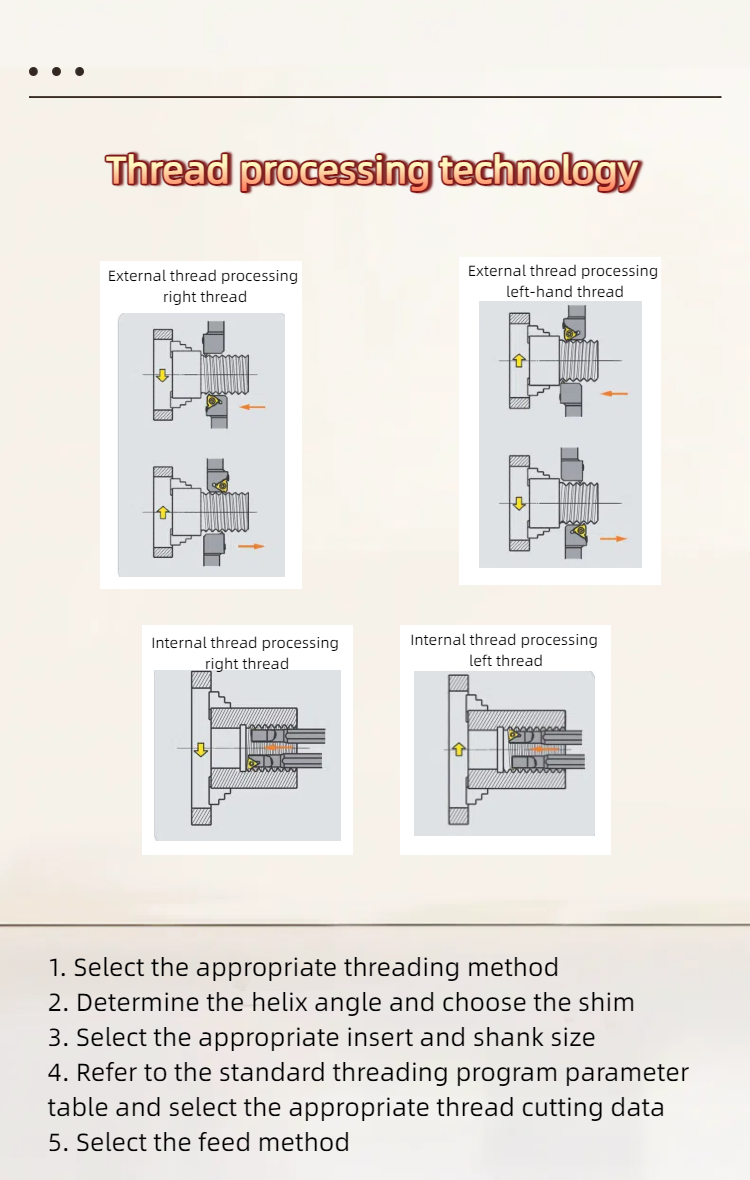

Thread processing technology

1. Select the appropriate threading method

2. Determine the helix angle and choose the shim

3. Select the appropriate insert and shank size

4.Refer to the standard threading program parametertable and select the appropriate thread cutting data

5.Select the feed method

ASP anti -vibration milling arbor

One rod for multipleuses, economical andefficient.

The threading shank canbe paired with a varietyof cutter heads, includinground nose cutter heads,square shoulder millingcutter heads, and ballcutter heads, achievingmulti-functionality.

Advantages of ASP Vibration-Improved Milling Cutter Bars

1. Solves "Vibration Issues"

2. Enhances Machining Efficiency

3. Ensures Long-Term Durability

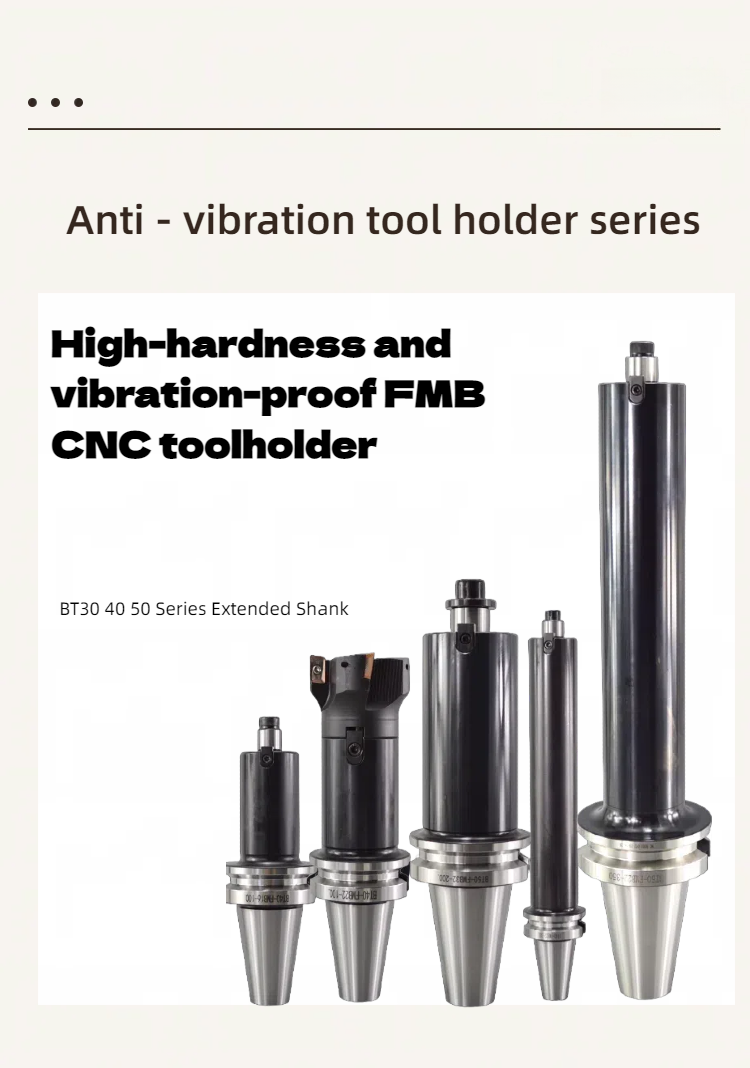

Anti -vibration tool holder series

High-hardness andvibration-proofFMBCNC toolholder