IRON ROOT ZTGD0404 Slotting Blades That Wow Users

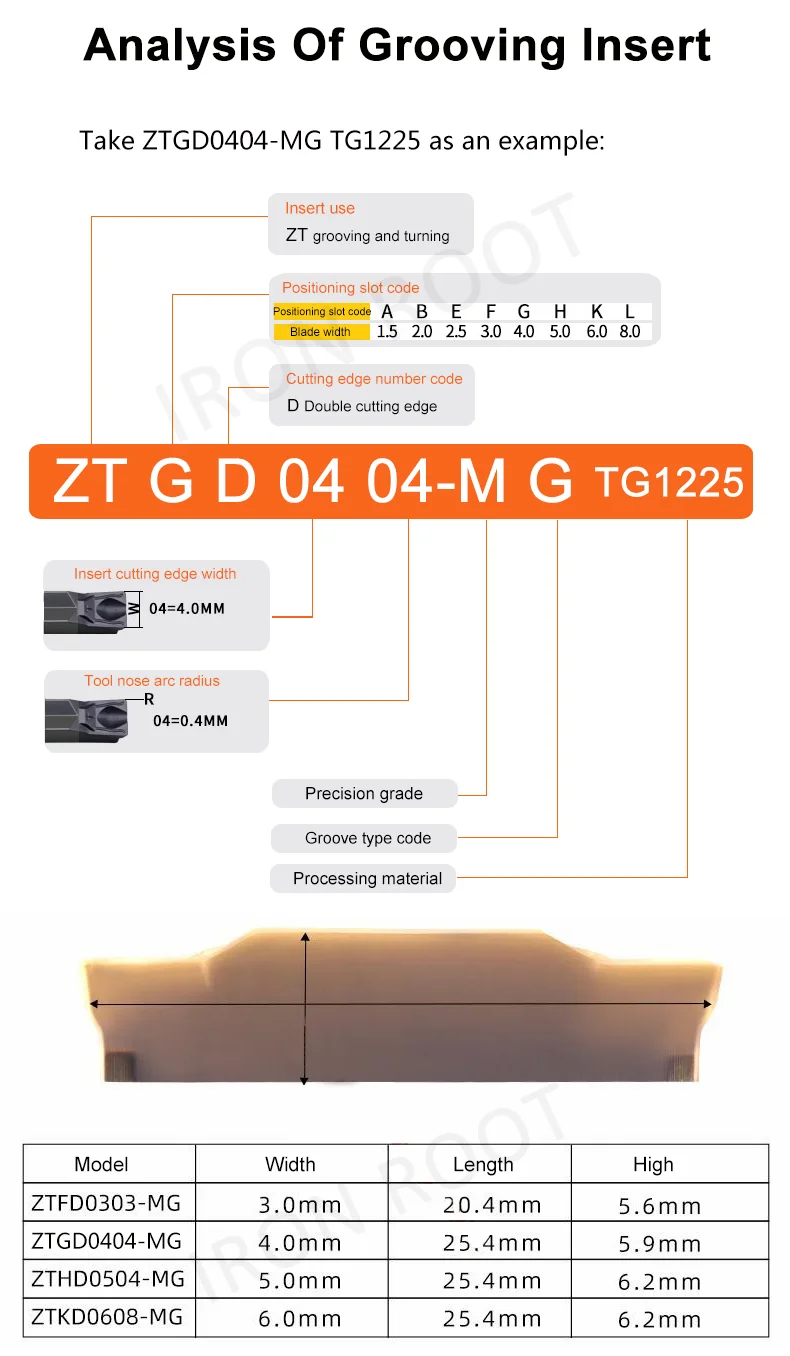

In the clanging, high-pressure world of metal machining, few things spark joy like a tool that turns a headache into a breeze. Just ask Mike Torres, a CNC lathe operator at a Michigan-based auto parts shop, who recently swapped his old slotting blades for the Carbide IRON ROOT ZTFD0303, IRON ROOT ZTGD0404, and IRON ROOT ZTHD0504-MG CNC slotting blades. “I used to dread slotting stainless steel—old blades would dull in an hour, leave jagged burrs, and turn my morning into a fight,” he says. “These new ones? It’s like slotting butter. I ran three 8-hour shifts straight on the ZTHD0504-MG, and it still cuts like it’s fresh out of the box.”

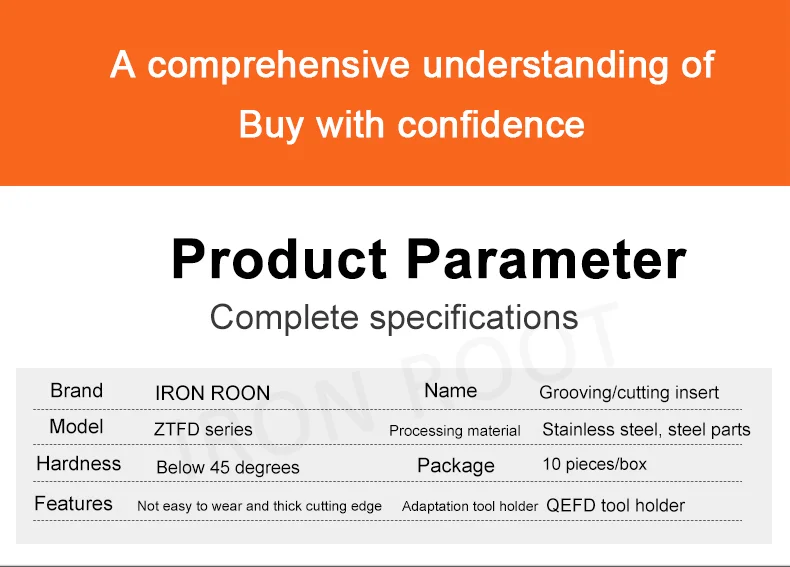

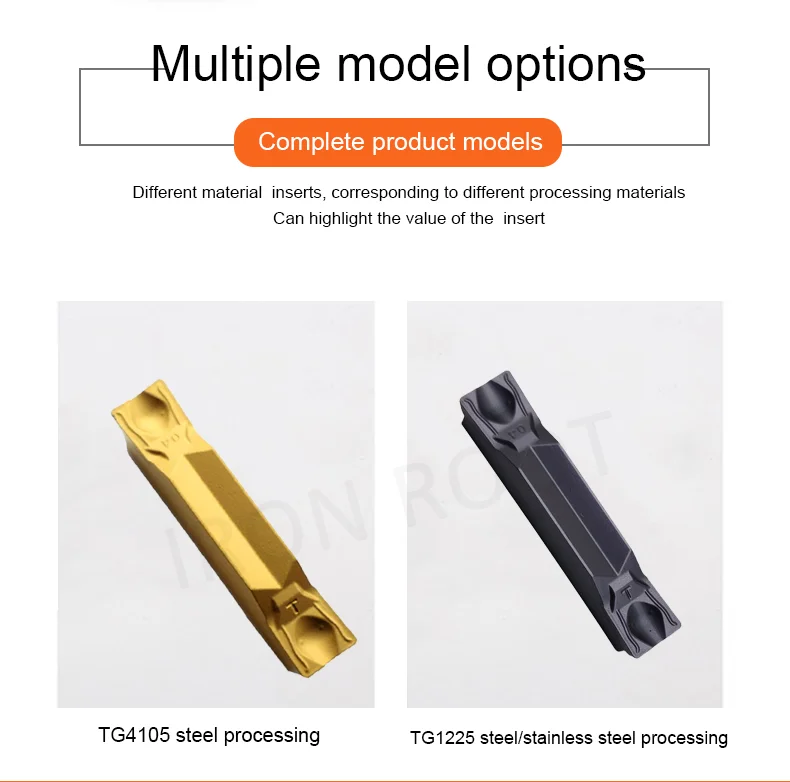

Torres isn’t alone. Across workshops, machinists are raving about the trio of tungsten carbide blades, engineered to tackle everything from carbon steel to tough cast iron. What makes them stand out? Start with the material: premium carbide delivers (hardness) that laughs off high temperatures, so even heavy-duty slotting sessions don’t wear them down. Then there’s the precision geometry—each blade’s edge is honed to slice clean, crisp grooves, slashing the need for post-machining sanding. “We used to spend 20% of our time fixing burrs,” says Lisa Wong, who runs a small precision parts shop in Ohio. “With the IRON ROOT ZTGD0404, our parts come off the lathe ready to ship. It’s cut our finishing time in half.”

The ZTHD0504-MG, with its mysterious “-MG” tag, is emerging as a fan favorite. While manufacturers stay tight-lipped on the exact specs, users swear by its “secret sauce”—likely a specialized coating that reduces friction and keeps chips from gumming up the works. “Stainless steel chips used to clog my machine like a bad drain,” Wong adds. “This blade? Chips fly off clean, no clogs, no stops. It’s magic.”

Whether it’s the nimble IRON ROOT ZTFD0303 for small slots or the workhorse IRON ROOT ZTHD0504-MG for heavy jobs, these blades are proving that in machining, the right tool doesn’t just save time—it turns frustration into satisfaction. As Wong puts it: “I’ve tried every slotting blade under the sun. These? They’ve earned a permanent spot in my toolbox.”

Looks like the era of battling dull blades is officially over—thanks to a trio of tiny but mighty carbide heroes.