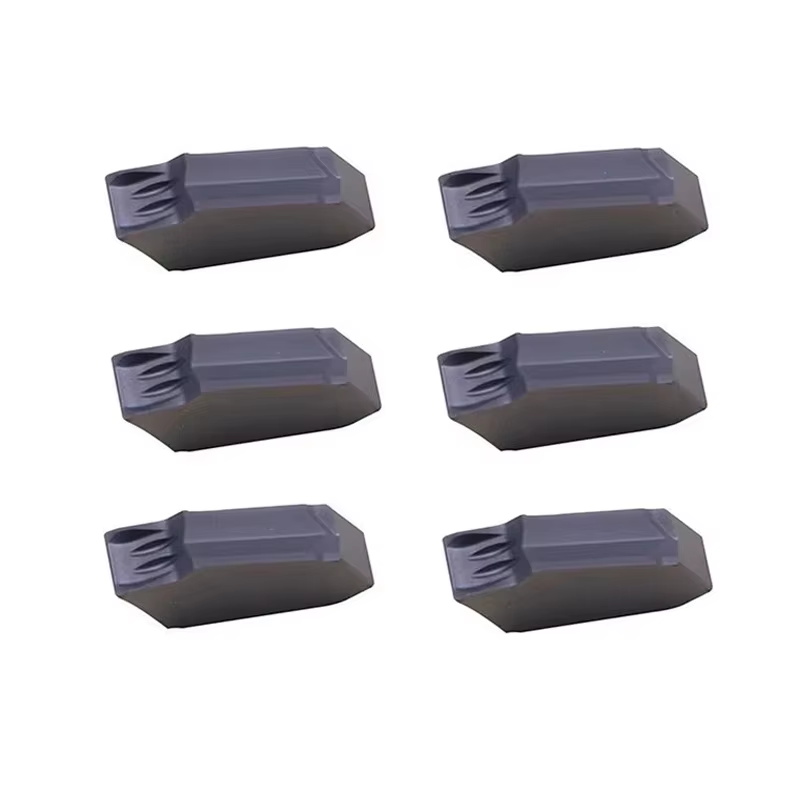

IRON ROOT SP Series: Machinists’ Grooving Favorites

Jake Carter, a CNC operator at a midwestern auto parts shop, used to start his mornings dreading one thing: slotting stainless steel. “Old inserts would dull by 10 a.m., leave ragged edges, and turn chips into a tangled mess,” he groans. “Now? I swap in an IRON ROOT SP400, and it runs all day—sharp, clean, no drama. It’s like upgrading from a rusty hacksaw to a laser.”

Carter isn’t the only one singing praises. Across the country, machinists are buzzing about the IRON ROOT SP200/SP300/SP400/SP500/TG1225 grooving carbide inserts, a tool that’s turning frustrating shifts into smooth sailing.

The secret? High-grade carbide that laughs off heat, so even hours of cutting tough metals don’t wear it down. Plus, that clever chip-breaker design—Carter swears by it. “Stainless steel chips used to clog my lathe like hair in a drain,” he says. “These inserts? Chips snap into little pieces and fly away. I haven’t stopped a job mid-run in weeks.”

And let’s not forget the time saved. “Before, I’d change inserts 3-4 times a shift,” Gonzalez adds. “Now? Once, maybe. That’s hours back to make more parts. My profit margin? Very happy.”

From auto shops to medical machining, these inserts are proving that sometimes, the smallest tools make the biggest waves. As Carter puts it, wiping down his lathe with a grin: “Why fight with bad tools when these make the job feel easy? I’m never going back.”