IRON ROOT From Dull to Dynamo: New Inserts Win Fans

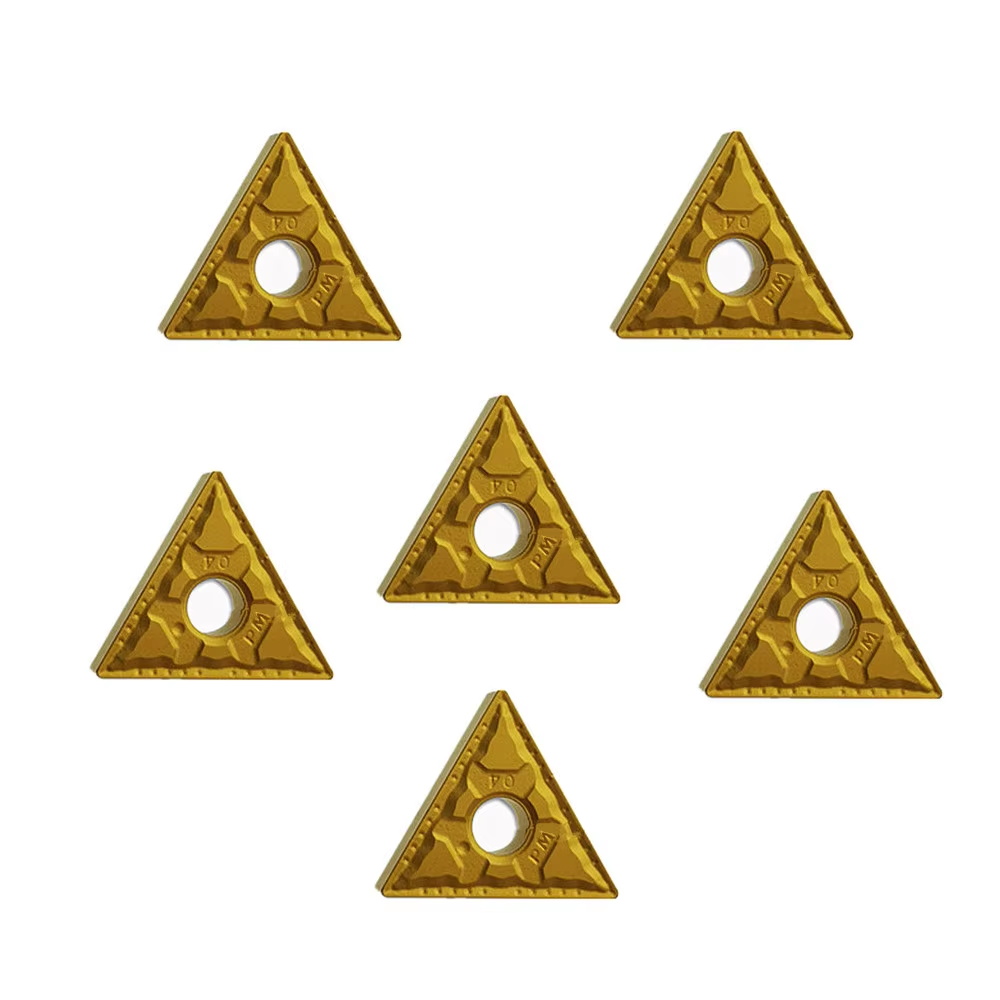

In the high-stakes world of CNC lathe operations, where precision and speed can make or break production deadlines, a new star has emerged: the IRON ROOT TNMG220408-PM and TNMG220404-PM tungsten carbide turning inserts. Designed specifically for steel machining, these small but mighty tools are earning rave reviews from manufacturers, with one shop foreman declaring, “It’s like swapping a rusty wrench for a laser—everything just clicks.”

Mark Henderson, who oversees a busy automotive parts workshop in Ohio, was skeptical at first. “We’ve tried dozens of inserts over the years, and most promise the moon but fizzle out after a few hours of heavy steel work,” he admits. That changed when his team tested the IRON ROOT TNMG220408-PM for roughing alloy steel axles. “Normally, we’d swap inserts every 40 minutes to keep up with quality—chips would gunk up, edges would dull, and we’d lose time adjusting. With these? We ran three hours straight without a hiccup. The finish on the steel was so smooth, our inspectors thought we’d switched to a new polishing step.”

Part of the magic lies in the inserts’ advanced makeup: a micrograin tungsten carbide substrate, polished to a “PM” finish that minimizes friction, and a triangular negative rake design that slashes cutting resistance. For Henderson’s team, this translated to faster feed rates and less machine vibration—a game-changer when machining high-tensile steel. “Our CNC lathe used to sound like a jackhammer during roughing. Now? It’s almost quiet. The operators keep asking if we the machine,” he laughs.

Over in Michigan, precision parts manufacturer Lisa Chen found her “aha moment” with the IRON ROOT TNMG220404-PM, the fine-finishing sibling. “We make medical equipment components—steel parts that need to fit together with zero tolerance. Even a tiny burr or rough spot means scrap,” she explains. “With our old inserts, we’d spend extra time sanding or re-machining. These? The 4mm radius cuts like a hot knife through butter. The surface is mirror-smooth right off the lathe. We’ve cut rework by 70%.”

Whether tackling heavy roughing or delicate finishing, the TNMG inserts are proving that in steel machining, the right tool doesn’t just save time—it transforms workflows. As Henderson puts it: “I’ve been in this business 20 years. These inserts? They’re not just good—they’re the kind of tool that makes you excited to come to work.”