Single - Thread Thread Milling Cutter Promotes High - Precision Thread Processing Technology Innovation

1. Core product highlights

Ultra-precision machining performance

Using 65° tungsten steel alloy material and nano-level coating technology, the thread machining accuracy is ±0.005mm, which is 300% longer than the traditional tool life18. Supports full specifications from metric fine teeth (such as M6×0.75) to coarse teeth (such as M24×3), and is suitable for high-hardness materials such as stainless steel and titanium alloy.

Intelligent process adaptation

The innovative single-tooth spiral blade design can be used with CNC programming to achieve "one-knife" machining, reduce the frequency of tool change and reduce 30% machining vibration, especially suitable for precision parts production scenarios such as medical equipment and aerospace.

Multi-scenario compatibility

Provides 12 types of tool body forms such as straight shank, extended shank, T-slot, etc., supports multi-equipment integration such as milling machine tools and five-axis machining centers, and meets the needs of mass production and single-piece proofing.

2. Industry value positioning

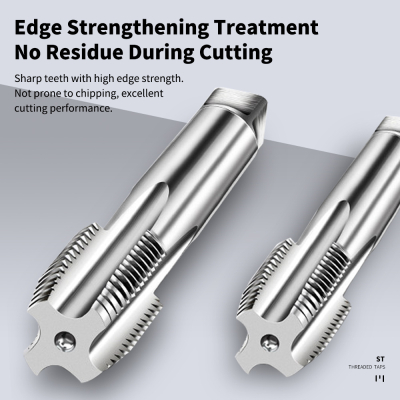

Solve pain points: Traditional thread milling cutters are prone to chipping and precision attenuation in fine tooth machining. This product breaks through the industry bottleneck through edge strengthening technology.

Core parameters:

Specifications covered: Supports M1-M24 metric fine/coarse threads, UNC/UNF imperial threads, and is compatible with NPT/NPTF pipe threads.

Material technology: Using 65° tungsten steel alloy or diamond coating (some models), the hardness reaches HRC89, and the life is increased by 300% compared with traditional tools.

Processing accuracy: Repeat positioning accuracy ±0.005mm, surface roughness Ra≤0.8μm.

Typical application scenarios

Medical devices: micro titanium alloy thread processing such as bone screws and implants, meeting ISO 13485 medical standards.

Aerospace: suitable for high-precision processing of aircraft engine parts and high-strength alloy bolts.

Precision molds: solve the problems of chipping and precision attenuation in deep cavity threads and hard material processing.