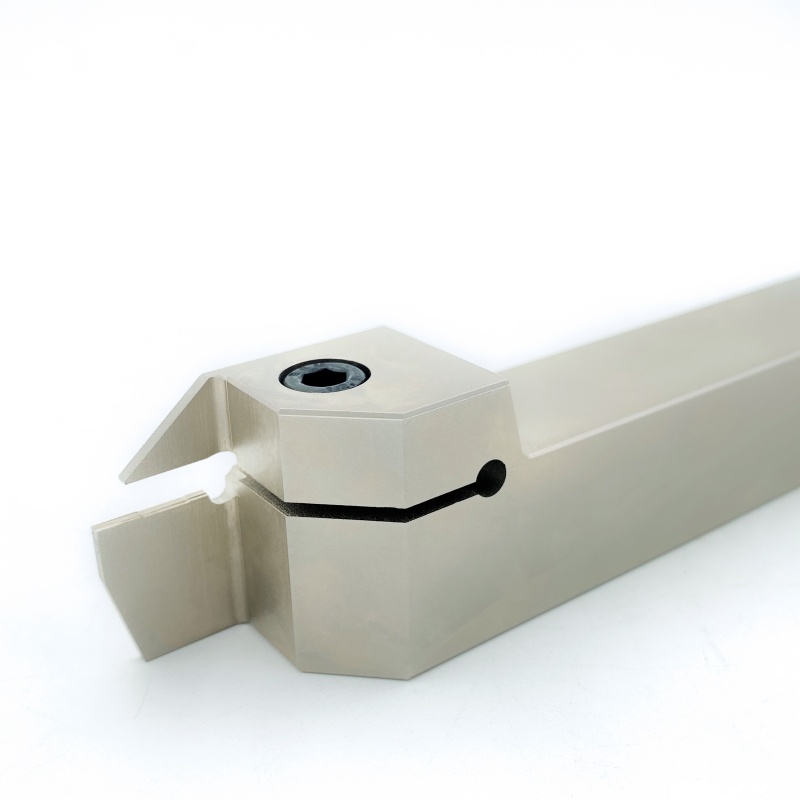

Carbide external grooving tool bar with anti-vibration design for CNC lathe/CNC machine tool

High-performance materials and processes

1. Wear resistance and impact resistance

Using high-quality materials such as carbide and tungsten steel, combined with advanced heat treatment processes, the durability of the tool bar is improved, and it is suitable for difficult-to-process materials such as high-strength alloy steel.

2. Modular design

Through high-precision positioning and rigid structure, it supports rapid blade replacement, reduces downtime, and improves production efficiency.

Precision processing and adaptability

1. High-precision cutting

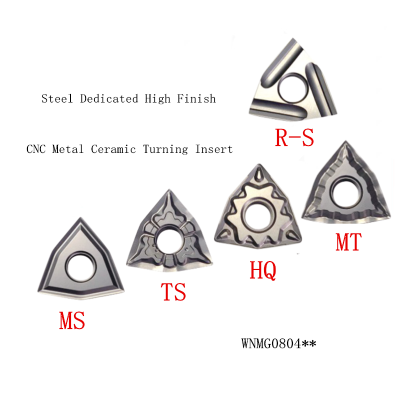

Adapt to R-type and standardized blades to ensure that the width and depth tolerances are controllable and meet the needs of high-finish processing.

2. Multi-scenario adaptation

Supports positive/negative tool bar, anti-vibration tool bar and other designs, compatible with CNC lathes, Swiss-type machines and other equipment.

Innovative structure and function

1. Cooling and heat dissipation optimization

The built-in cooling channel design effectively reduces the cutting temperature, extends the tool life, and prevents workpiece deformation.

2. Composite processing capabilities

Some models integrate end face, outer circle, and grooving functions to reduce the number of tool changes.

Technical analysis and application value of GK series of external cylindrical grooving tool bars

The GK series of external cylindrical grooving tool bars is a modular tool system designed for high-precision and high-intensity processing scenarios. Its technical characteristics and structural innovations have significant advantages in the industrial field. The following is a detailed description from four dimensions: technical parameters, structural design, adaptability, and application scenarios:

The GK series adopts a standardized interface design, supports rapid replacement of blades and cutter head modules, and is suitable for a variety of cutting scenarios. The tool bar sizes cover common specifications such as 1616, 2020, 2525, and 3225, and can be flexibly matched with different machine tool turrets. It is suitable for MT groove blades, supports groove width tolerance control within ±0.01mm, and the surface roughness can reach Ra0.8μm, which is especially suitable for high finish processing requirements. The cutting depth can reach more than 20mm. By strengthening the rigidity of the tool bar and the shockproof design, the vibration and deformation during processing are reduced, which is suitable for complex structure processing such as deep grooves and narrow grooves.

2. Structural design and innovative highlights

Modular split structure

The cutter head and the tool handle are connected by high-precision positioning pins, which ensures rigidity and facilitates maintenance. Some models have integrated coolant channels that can directly reach the cutting area, reduce the risk of thermal deformation, and extend the tool life.

Anti-interference and anti-vibration optimization

The cutter head adopts a low-profile design to reduce the risk of interference with the workpiece, especially suitable for narrow space processing such as small diameter parts and hub flanges. The built-in damping structure can effectively suppress high-frequency vibration and improve cutting stability.

Multi-directional feed adaptability

Supports positive and reverse tool bar configurations to meet different feed direction requirements. The blade clamping mechanism adopts wedge locking technology to ensure that the blade works stably under high load.

3. Typical application scenarios and industry coverage

Automotive parts processing

Suitable for high-precision grooving requirements such as wheel hub flange grooves and piston ring grooves. It is compatible with materials such as aluminum alloys and cast iron. A single process can complete the composite cutting of grooves and end faces.

Aerospace precision machining

For difficult-to-cut materials such as titanium alloys and high-temperature alloys, the GK series achieves high-efficiency and low-loss machining by optimizing the coating and tool tip geometry, which is especially suitable for deep groove machining of engine parts and landing gear parts.

Mold manufacturing and small parts processing

Micro tool bars (such as 1616 size) support precision parts processing and reduce material waste. The composite tool design can integrate turning and grooving functions, significantly improving the processing efficiency of small mold inserts and precision shaft parts.

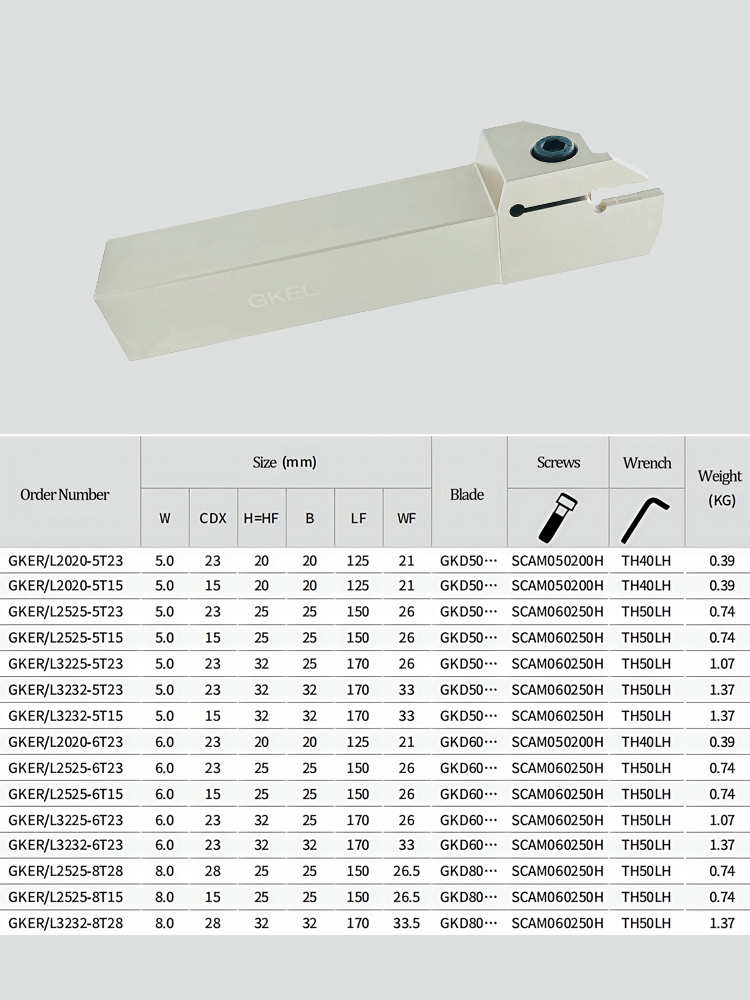

| Order Number | Size (mm) | Blade | ScrewS | Wrench | Weight(KG) | |||||

| GKER/L2020-5T23 | 5.0 | 23 | 20 | 20 | 125 | 21 | GKD50… | SCAM050200H | TH40LH | 0.39 |

| GKER/L2020-5T15 | 5.0 | 15 | 20 | 20 | 125 | 21 | GKD50… | SCAM050200H | TH40LH | 0.39 |

| GKER/L2525-5T23 | 5.0 | 23 | 25 | 25 | 150 | 26 | GKD50… | SCAM060250H | TH50LH | 0.74 |

| GKER/L2525-5T15 | 5.0 | 15 | 25 | 25 | 150 | 26 | GKD50… | SCAM060250H | TH50LH | 0.74 |

| GKER/L3225-5T23 | 5.0 | 23 | 32 | 25 | 170 | 26 | GKD50… | SCAM060250H | TH50LH | 1.07 |

| GKER/L3232-5T23 | 5.0 | 23 | 32 | 32 | 170 | 33 | GKD50… | SCAM060250H | TH50LH | 1.37 |

| GKER/L3232-5T15 | 5.0 | 15 | 32 | 32 | 170 | 33 | GKD50… | SCAM060250H | TH50LH | 1.37 |

| GKER/L2020-6T23 | 6.0 | 23 | 20 | 20 | 125 | 21 | GKD60… | SCAM050200H | TH40LH | 0.39 |

| GKER/L2525-6T23 | 6.0 | 23 | 25 | 25 | 150 | 26 | GKD60… | SCAM060250H | TH50LH | 0.74 |

| GKER/L2525-6T15 | 6.0 | 15 | 25 | 25 | 150 | 26 | GKD60… | SCAM060250H | TH50LH | 0.74 |

| GKER/L3225-6T23 | 6.0 | 23 | 32 | 25 | 170 | 26 | GKD60… | SCAM060250H | TH50LH | 1.07 |

| GKER/L3232-6T23 | 6.0 | 23 | 32 | 32 | 170 | 33 | GKD60… | SCAM060250H | TH50LH | 1.37 |

| GKER/L2525-8T28 | 8.0 | 28 | 25 | 25 | 150 | 26.5 | GKD80… | SCAM060250H | TH50LH | 0.74 |

| GKER/L2525-8T15 | 8.0 | 15 | 25 | 25 | 150 | 26.5 | GKD80… | SCAM060250H | TH50LH | 0.74 |

| GKER/L3232-8T28 | 8.0 | 28 | 32 | 32 | 170 | 33.5 | GKD80… | SCAM060250H | TH50LH | 1.37 |

The GK series of external cylindrical grooving tool bars have become an efficient solution in complex processing environments through modular design, precision manufacturing technology and scenario-based adaptability. Its technical advantages are not only reflected in processing accuracy and efficiency, but also provide continuous value to multiple industries through flexible scalability. It is a key tool carrier to promote the upgrade of precision manufacturing.