IRON ROOT Carbide ZTFD0303 ZTGD0404 ZTHD0504-MG CNC slotting blade

Product Details

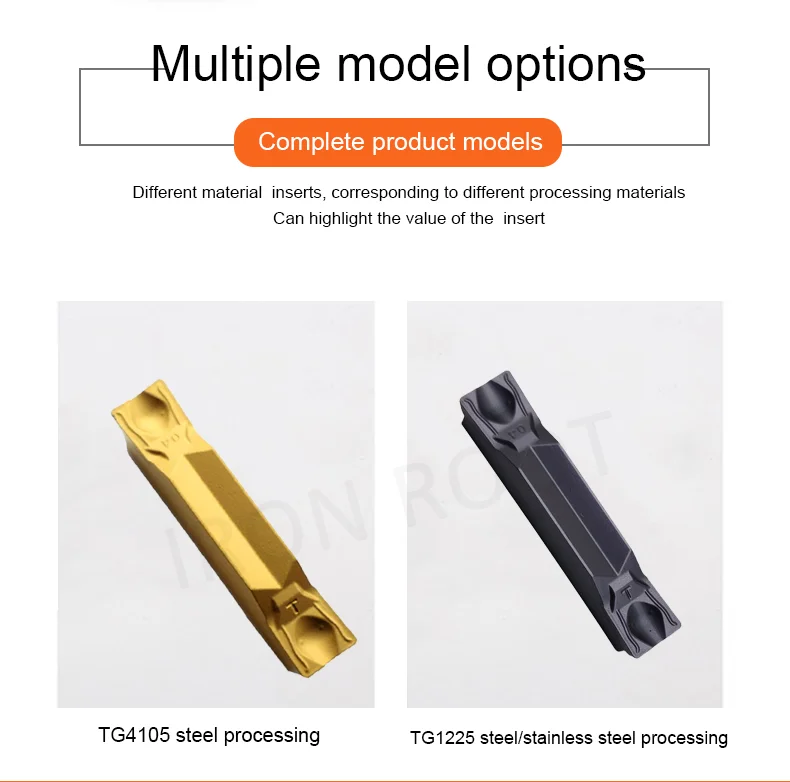

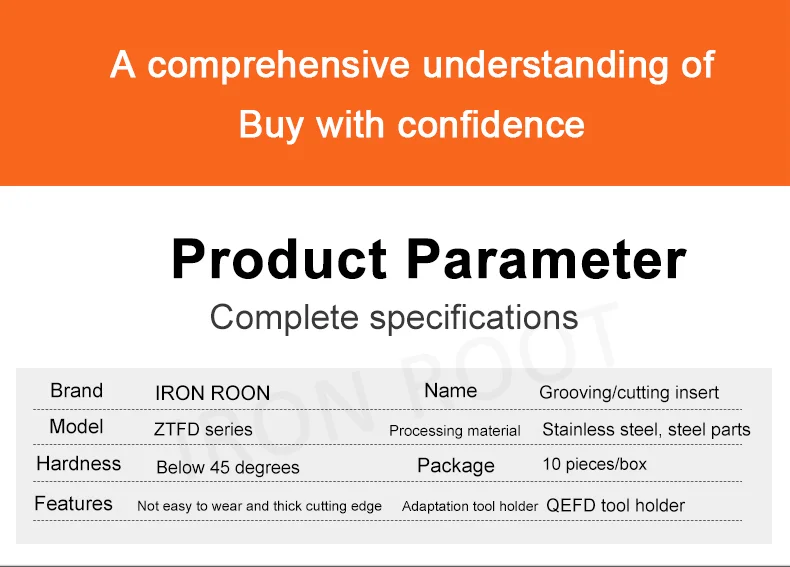

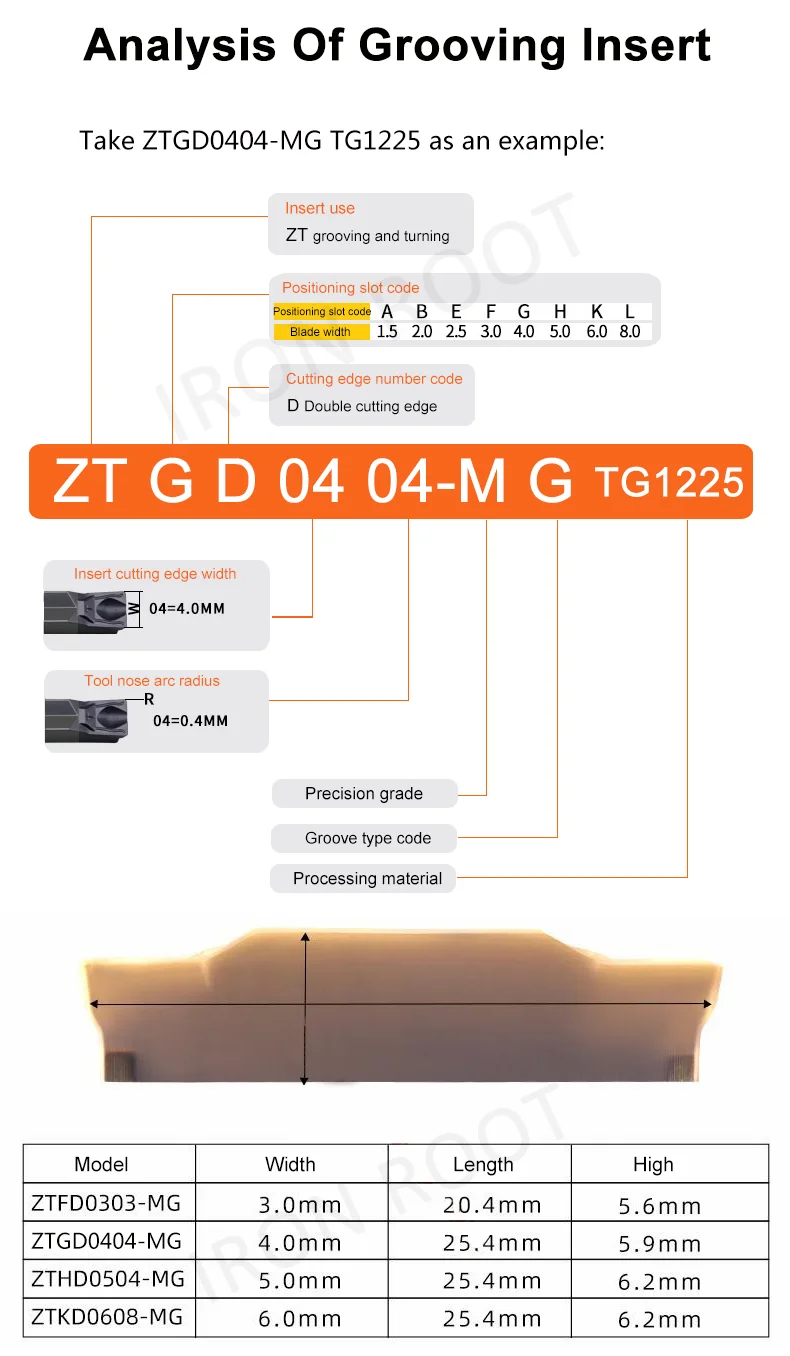

The Carbide IRON ROOT ZTFD0303,IRON ROOT ZTGD0404, and ZTHD0504-MG CNC slotting blades stand as precision-engineered solutions for high-performance metal slotting operations, designed to meet the demands of modern CNC lathe machining with uncompromising efficiency.

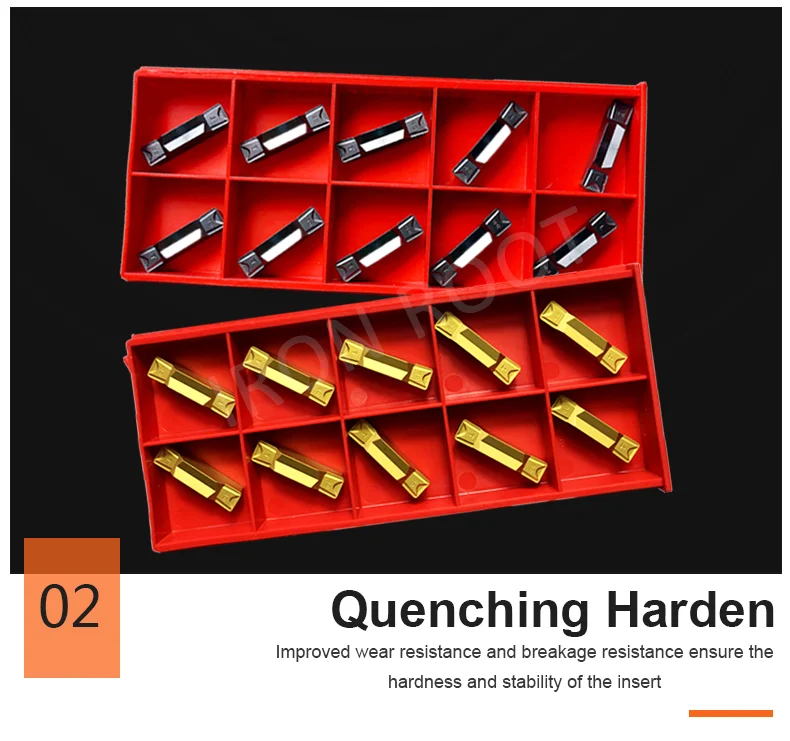

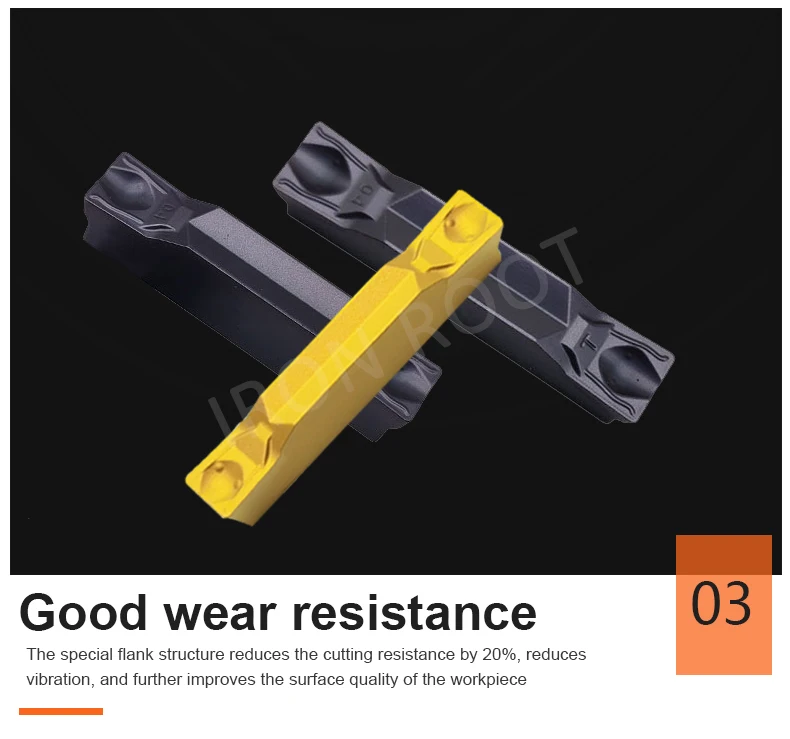

Forged from high-grade tungsten carbide, these blades boast exceptional hardness and wear resistance, making them ideal for tackling a wide range of metals—including carbon steel, cast iron, and stainless steel. Their robust construction enables them to endure the extreme temperatures and cutting pressures of continuous, heavy-duty slotting, significantly extending tool life compared to standard inserts and reducing the frequency of tool changes.

Each model features a specialized geometry tailored to slotting tasks: the IRON ROOT ZTFD0303 and IRON ROOT ZTGD0404 excel in creating clean, precise grooves with tight dimensional tolerances, minimizing burr formation and reducing the need for post-machining finishing. The IRON ROOT ZTHD0504-MG, marked by the "-MG" designation, often incorporates an advanced coating or substrate enhancement that lowers friction between the blade and workpiece, optimizing chip evacuation to prevent clogging—a critical advantage when working with sticky or high-alloy materials.

Compatible with standard CNC lathe setups, these blades ensure seamless integration into existing workflows, with quick installation and secure clamping reducing downtime. Whether used for small-scale precision slotting in mold making or high-volume production of automotive components, they deliver consistent performance, balancing speed and accuracy to boost overall productivity.

For manufacturers seeking reliable, long-lasting tools to elevate their slotting operations, the IRON ROOT ZTFD0303, IRON ROOT ZTGD0404, and ZTHD0504-MG carbide blades offer a winning combination of durability, precision, and versatility.

Leave your messages