VBMT Insert: Key Uses in CNC Turning

VBMT Insert: Key Uses in CNC Turning

IronRoot VBMT Inserts: The "Precision Pros" Changing CNC Lathe Turning

For CNC machinists tired of settling for "good enough" when turning metal, there’s a new hero in town: ironroot VBMT inserts. And not just any VBMT inserts—ironroot VBMT insert, the star of iron root’s (often stylized as ironroot) top-tier CNC Lathe Tool lineup. These little carbide powerhouses turn finicky finishing jobs into smooth wins, and once you decode their secrets (like ironroot vbmt insert full form or angle), you’ll see why shops are ditching old tools for IronRoot’s version.

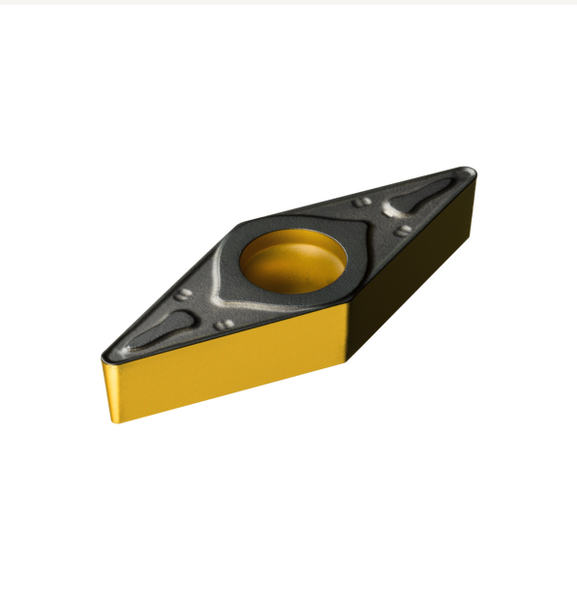

Let’s start with the basics: What even is a VBMT insert? First, crack the ironroot vbmt insert full form—it’s an ISO code that tells you everything you need to know:

V: Rhombic (diamond) shape (sleek and sharp for tight spaces!)

B: 5° clearance angle (balances sharpness and strength)

M: Medium tolerance (fits most setups without fussy tweaks)

T: Thin insert design (lightweight but tough enough for steel)

And that ironroot vbmt insert angle (or vbmt insert oegree, for those who mix up spellings)? A crisp 35°—the "sweet spot" for precision. It’s sharp enough to leave mirror-smooth finishes but strong enough to handle semi-roughing, too. “That 35° angle changed everything,” says Maria Gonzalez, a CNC operator at an aerospace parts shop. “Before, I’d need two inserts: one for roughing steel, one for finishing. Now, one ironroot VBMT Insert does both. It glides through titanium alloy like it’s aluminum, and the finish? My boss thought I bought a new lathe.”

Let’s talk ironroot vbmt insert specification—IronRoot doesn’t cut corners here. Their VBMT inserts come in popular sizes (like VBMT110304, with 11mm edge length and 0.4mm nose radius) and are coated with TiAlN for extra wear resistance. “We make hydraulic valves that need 0.0005” accuracy,” explains Jake Miller, owner of a precision machining shop. “IronRoot’s specs are spot-on—no more measuring inserts to check if they’ll fit. The ironroot vbmt insert nomenclature is simple, too: ‘VBMT110304’ tells me edge length, thickness, and nose radius at a glance. No more squinting at confusing labels.”

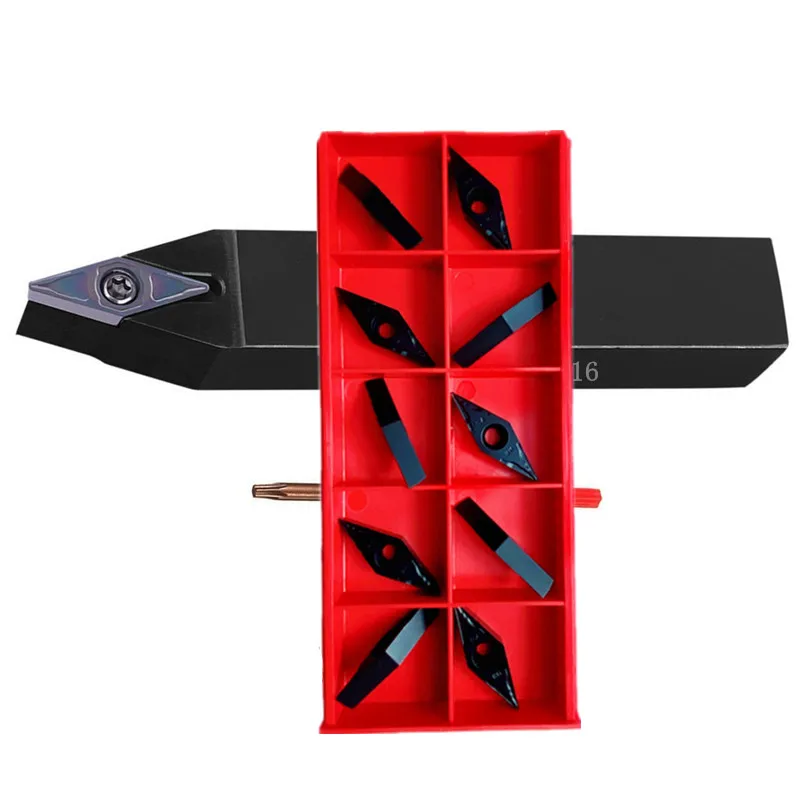

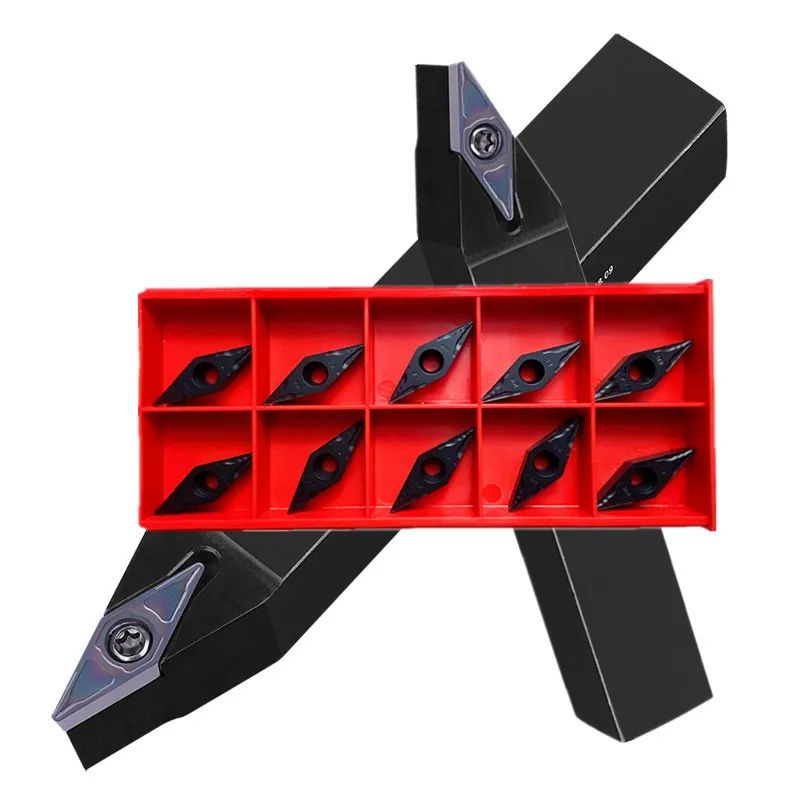

A great insert needs a great home, and IronRoot’s ironroot vbmt insert tool holder (or vbmt insert holder, for short) delivers. It locks the insert tight, so no wobbling mid-cut—critical for hitting tight tolerances. And if you need to bore holes? Their ironroot vbmt insert boring bar turns the same insert into an internal turning pro. “We used to have a separate boring tool that cost $200,” Jake laughs. “Now, I just pop my IronRoot VBMT into the boring bar—same precision, half the cost. It’s saved us so much money, we upgraded our coolant system.”

Let’s not forget ironroot vbmt insert price—a big win for shops on a budget. IronRoot’s VBMT inserts start at just 15 on inserts that lasted 30 parts,” Maria admits. “IronRoot’s? One insert lasts 100+ parts. My tool budget’s cut in half—my team gets pizza Fridays now!”

Whether you’re finishing aerospace alloys, turning stainless steel valves, or boring precision holes, ironroot VBMT Inserts are the tool that just works. They’re part of why ironroot’s CNC Lathe Tool lineup is taking over shops—reliable, affordable, and built for machinists who demand perfection.

As Maria puts it: “These inserts don’t just do the job—they make my job easier. I used to dread Monday mornings; now I walk in, grab my IronRoot VBMT, and knock out 50 parts before lunch. Who knew an insert could make me happy?”