Carbide Inserts: CNC Lathe Turning Use

Carbide Inserts: CNC Lathe Turning Use

When Mike Chen, owner of Precision Turn Machining in Guangzhou, was struggling with frequent tool failures while machining aluminum parts earlier this year, he never expected a switch to carbide inserts to turn his workshop’s fortunes around. “We were using cheap generic tools before—they’d wear out after just 50 aluminum parts, and the surface finish was terrible,” Chen recalled. “Now, with ironroot carbide inserts, we’re hitting 200 parts per insert, and the quality is consistent enough to sell to European clients.”

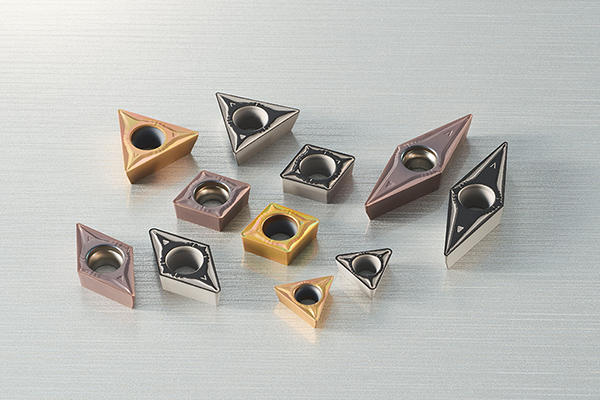

ironroot, a rising name among carbide insert manufacturers based in Jinan, specializes in tailored solutions for metalworking, including their popular carbide inserts for aluminum. Unlike standard tools, ironroot’s carbide inserts feature a TiAlN coating— a thin, heat-resistant layer that reduces friction and prevents aluminum from sticking to the cutting edge, a common headache for machinists. “The coating is a game-changer,” Chen said. “We used to stop every 10 minutes to clean the tool; now we run 2-hour shifts without interruptions.”

3.50 per piece, and they arrive in 2 days in a sturdy carbide insert box that keeps the tools from getting damaged. We even checked the carbide insert HS code (8208.10.00 for indexable carbide inserts) to make sure customs clearance was smooth—no delays at all.”

To pair with the new inserts, Chen invested in ironroot’s carbide insert tool holder, designed to lock the inserts in place with zero wobble. “Precision is everything when you’re making parts for automotive clients,” he said. “The tool holder keeps the carbide insert aligned to within 0.001mm, so every part meets the blueprint.”

Chen’s experience isn’t unique. As demand for high-quality yet affordable machining tools grows, more small workshops are turning to carbide inserts China suppliers. “carbide insert We’ve seen a 60% jump in orders from small to mid-sized shops this year,” said Li Mei, sales manager at ironroot. “Our clients love that we offer both standard carbide inserts and custom options—like our ironroot carbide inserts for high-temp alloys—and we always include coating samples so they can test performance first.”

For Chen, the carbide insert results speak for themselves. “Our output is up 40%, scrap rates are down to 2% from 15%, and we just hired two more workers,” he said with a smile. “Who knew a small carbide insert could make such a big difference?”