What is a U-drill?

What is a U-drill?

Let’s be real: Drilling holes in metal used to be the most soul-sucking part of a CNC machinist’s day. Slow speeds, tangled chips, and u drill bit replacements that ate into budgets—until IronRoot showed up. The brand’s IronRoot CNC tools lineup has already won fans, but their IronRoot U-drill? It’s the "hole-making rockstar" that’s turning groans into high-fives. From u drill size options to budget-friendly u drill price tags, here’s why machinists can’t stop raving.

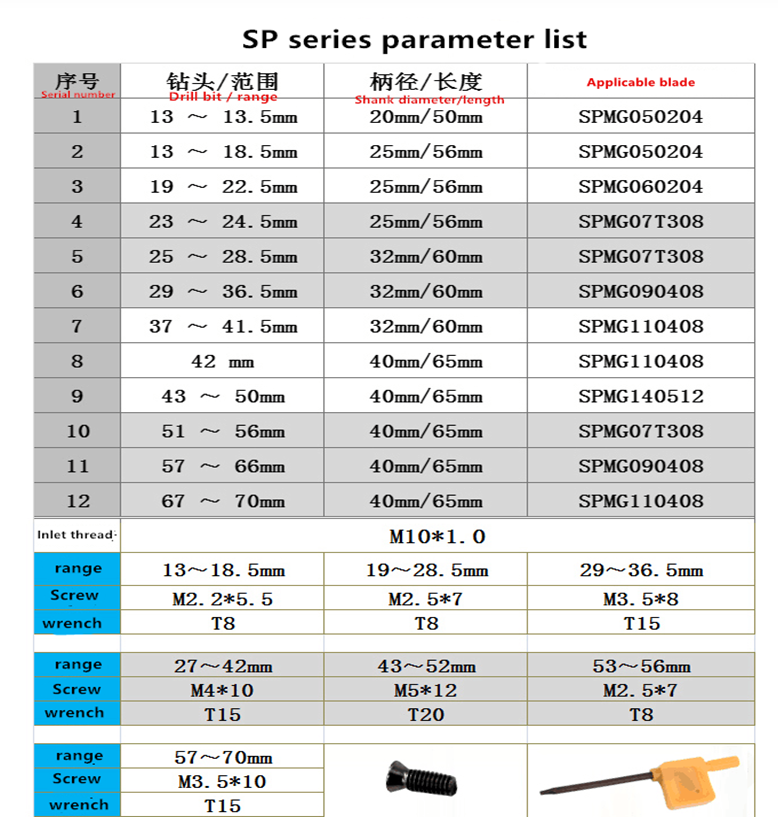

First, let’s break down the star: An IronRoot U-drill isn’t your grandma’s twist drill. It’s a heavy-duty u drill bit that uses replaceable u drill insert (yes, plural—u drill inserts!) instead of a single solid edge. When one insert wears out? Swap it in 10 seconds—no need to toss the whole drill. That’s a game-changer for anyone tired of wasting money on disposable bits.

IronRoot gets that not every shop speaks metric—and that’s why their u drill size range covers both worlds. Need a tiny hole for a bolt? Grab their 3/8” model (a popular u drill bit size in fraction). Machining a big bore for a hydraulic cylinder? Go for the 1-1/2” option. “I used to have a drawer full of random drill bits, never the right fraction,” says Mia Carter, owner of a small CNC shop. “Now, IronRoot’s size chart has every u drill size I need—3/16”, 5/8”, you name it. No more guessing if a 11/32” will work. It’s like they read my mind.”

Ever burned up a drill because you guessed wrong on RPM? IronRoot solved that with their u drill speeds and feeds calculator (yes, it’s free on their website!). Plug in your material (steel, aluminum, cast iron) and u drill size, and it spits out the perfect settings. “I’m a new machinist, so speeds and feeds terrified me,” admits Raj Patel, who works at an automotive parts plant. “Last week, I used the calculator for an IronRoot U-drill on aluminum—2,200 RPM, 0.006” feed. It cut like butter, no burns, no scrap. I felt like a pro.”

Let’s talk u drill price—because no one wants to break the bank. IronRoot’s U-drills start at 8 each. Compare that to premium brands that charge 300 a month on drill bits,” says Jake Miller, a CNC supervisor. “Now, with IronRoot U-drills, we’re down to $75. The inserts last 50+ holes, and the drill body? We’ve had the same one for 6 months. It’s saved us so much money, we got a team lunch bonus!”

And let’s not forget: These are CNC tools through and through. The IronRoot U-drill locks into standard CNC setups, and the rigid body minimizes vibration—so every hole is straight and precise. “We make aerospace parts that need 0.001” accuracy,” Jake adds. “IronRoot’s U-drills hit that every time. Before, we’d have to ream holes; now, we drill and done. It’s cut our cycle time by 40%.”

At the end of the day, the IronRoot U-drill isn’t just a tool—it’s a time-saver, a budget-saver, and a sanity-saver. As Mia puts it: “I used to dread drill days. Now? I grab my IronRoot U-drill, punch settings into the calculator, and knock out 50 parts before lunch. Who knew a drill could make me happy?”