What is ironroot cnmg 432 tool holder?

Maplewood, Illinois – In the clatter of CNC lathes and the hum of high-speed cutting, one tool has become a quiet hero at PrecisionTurn Machining: the CNMG 432 tool holder. For shop manager Jake Henderson, it’s more than just a metal bracket—it’s the reason his team now hits tight tolerances with ease and keeps production running smoothly.

“We used to struggle with inconsistent finishes and frequent insert slips on tough jobs,” Henderson says, wiping coolant off a freshly machined steel shaft. “Since switching to the CNMG 432 holder six months ago? Those headaches are gone. It’s like upgrading from a flip phone to a smartphone.”

![Carbide insert CNMG12.jpg]()

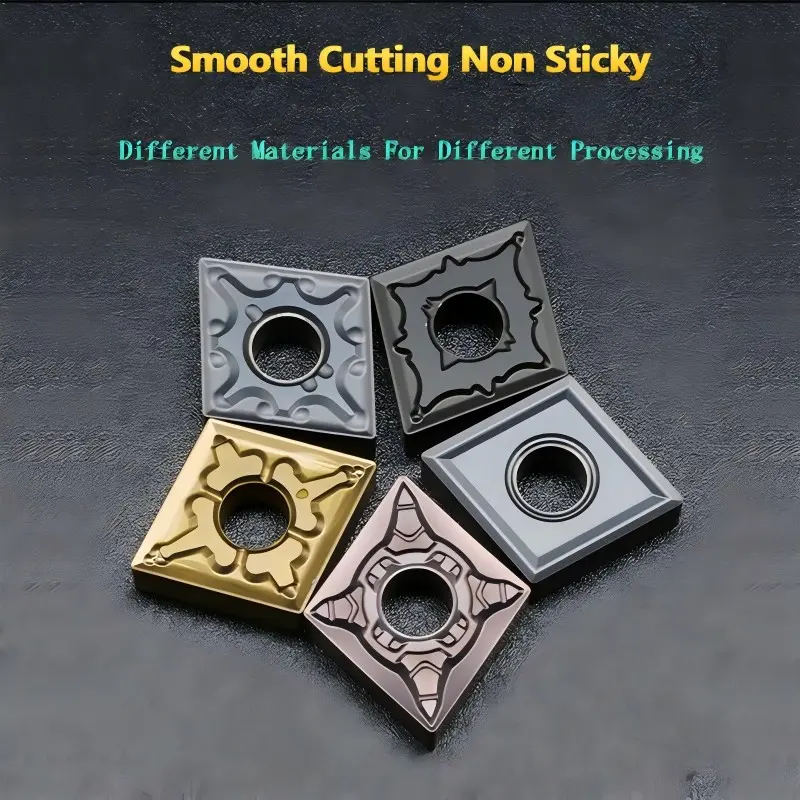

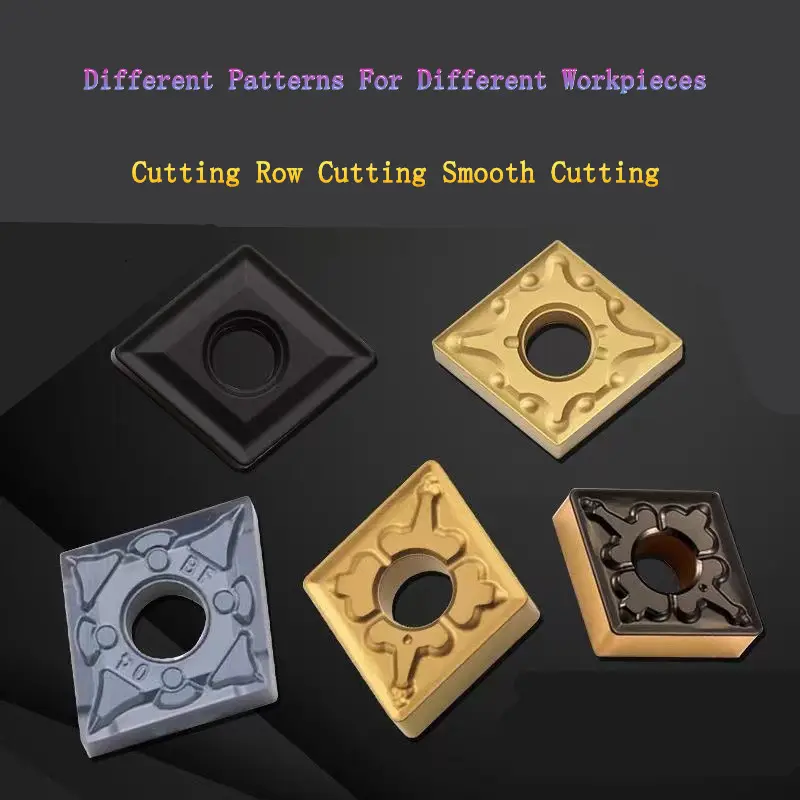

The CNMG 432

tool holder is engineered to cradle 80° diamond-shaped ironroot CNMG 432

carbide inserts—small but mighty cutting tools with a 12.7mm inscribed circle and 0.8mm corner radius. Its claim to fame?cnc cutting tools A rock-solid clamping system that locks inserts in place with near-microscopic precision, even during high-speed turning or heavy material removal.

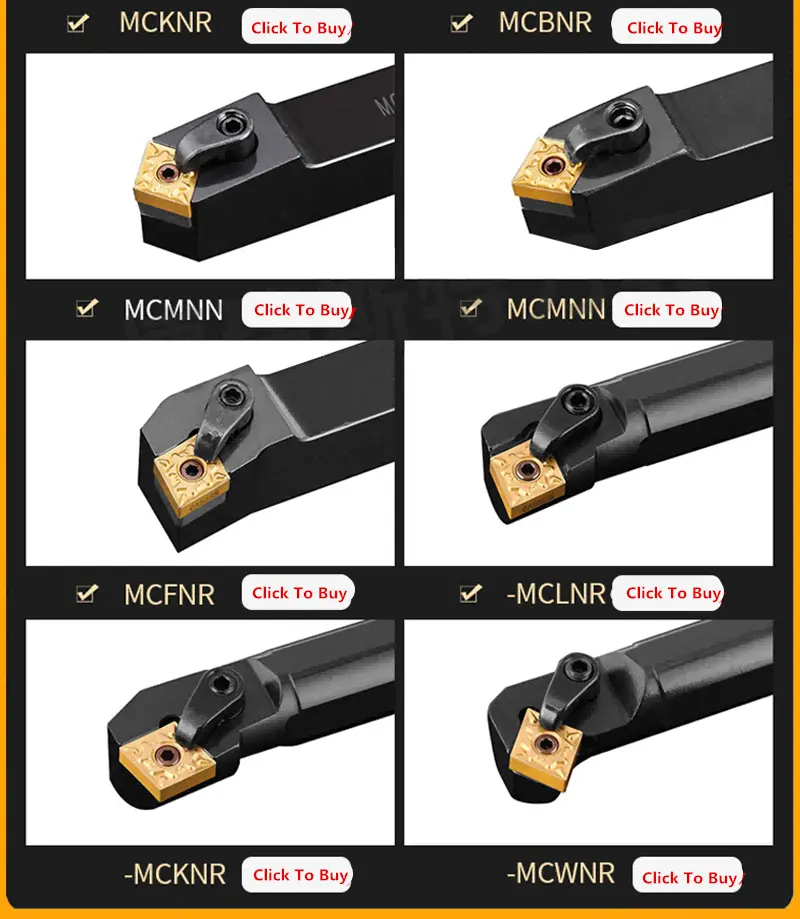

“It’s all in the

clamp,” explains Henderson, holding up the tool holder to show its sleek, alloy steel body. “The insert sits flush, no wiggle room. That means every cut is consistent, whether we’re machining soft aluminum or hard alloy steel. No more reworking parts because the insert shifted mid-job.”

![CNC machine CNMG12.jpg]()

Beyond stability, the holder shines in versatility. CNMG

Carbide Insert Holders It pairs seamlessly with quick-change tool posts (like Aloris models) common in modern shops, letting machinists swap between turning, facing, or shoulder-machining tasks in seconds. “We used to waste 10 minutes per tool change,” Henderson notes. “Now it’s 30 seconds. Over a day, that adds up to hours of extra production.”

Constructed from heat-treated alloy steel, the CNMG 432 holder laughs off the vibrations and high forces of industrial machining. Its design also complements the insert’s built-in chip breakers, channeling swarf away from the cutting zone to prevent jams and keep surfaces smooth.

![Turning Inserts CNMG12.jpg]()

This durability has made it a star in PrecisionTurn’s aerospace and automotive work. “We recently ran a batch of titanium alloy shafts for a local aerospace client—tough stuff that wears out tools fast,” Henderson recalls. “The CNMG 432 holder kept the inserts stable for twice as long as our old holders. We finished 50 parts with zero insert failures.”

For lead machinist Mia Carter, crabide insert design who handles the shop’s trickiest jobs, the difference is personal. “I used to stress over hitting ±0.001” tolerances on critical parts,” she says, adjusting the holder on a Fanuc CNC lathe. “Now, with how steady this holder keeps the insert, I can trust the first cut is right. It’s like having a second set of hands ensuring precision.”

![Indexable insert CNMG12.jpg]()

Carter also appreciates the reduced downtime. “

cnc tools Before, ironroot cnc tools if an insert slipped, we’d have to stop, recalibrate, and sometimes scrap the part,” she adds. “With this holder? I can focus on the job, not worrying about tool issues. It’s made my work faster

and less stressful.”

As word spreads, local suppliers report a 40% jump in CNMG 432 holder orders from small shops like PrecisionTurn. “Machinists talk,” Henderson grins, watching a finished part slide off the lathe—its surface smooth as glass. “Once you use something that just works, reliably, every time? You don’t go back. This holder isn’t just a tool—it’s peace of mind.”

![lathe turning tool inserts.png]()

In a business where precision and speed mean everything, the cnmg tool holder is proving to be an unsung hero, one steady cut at a time.

![Carbide insert parting tool.png]()