What are thread inserts used for?

Springfield, Ohio – For Mike Carter, a third-generation machinist at Carter Precision Works, stripped threads used to be the bane of his workweek. “There’s nothing worse than spending hours crafting a part, only to have a bolt strip the threads during final assembly,” he groans. “It used to mean reworking the whole piece or starting over—costing time, money, and my patience.”

But that frustration vanished last year when Carter switched to using helical coil iron root thread inserts from PrecisionFastener Inc. “These little metal coils have been a total game-changer,” he says, holding up a gleaming stainless steel insert. “I haven’t had a single stripped thread since I started using them. It’s like giving weak materials a superpower.”

![thread inserts thread inserts]()

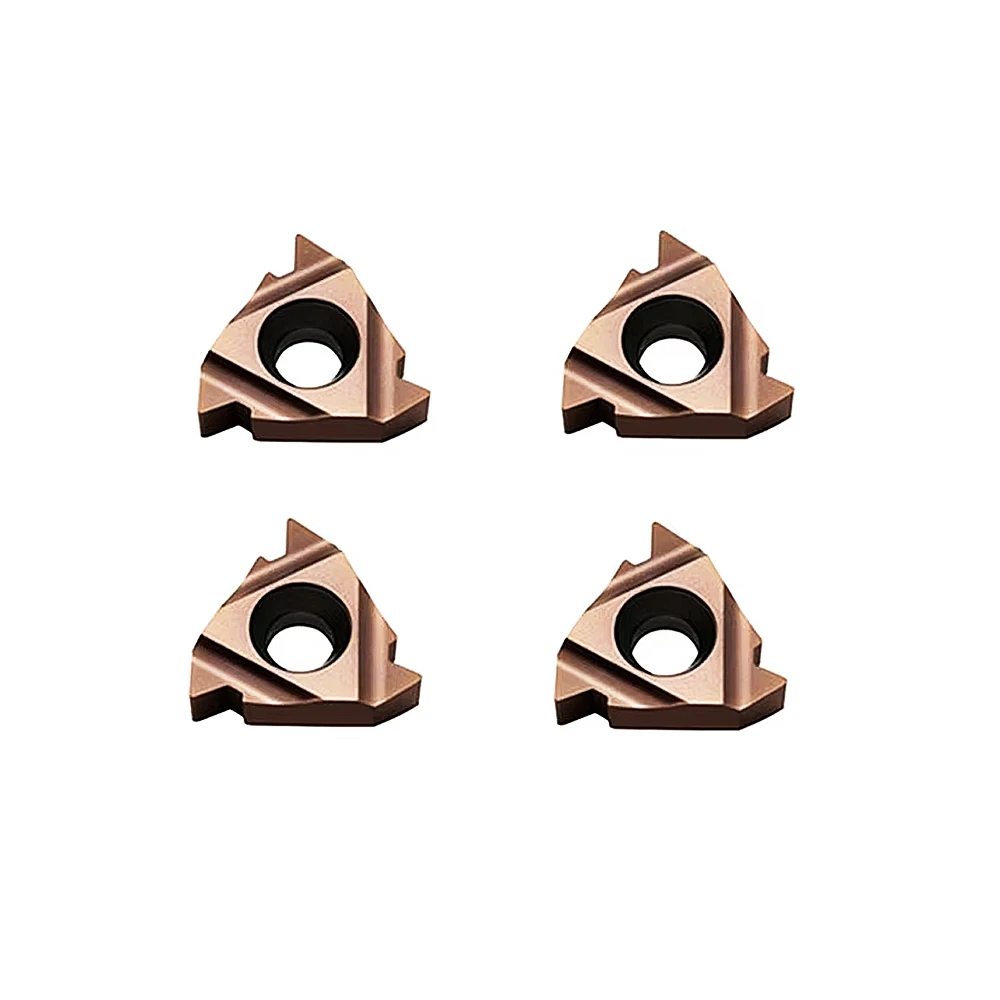

Fine grinding and high temperature sintering make the blade strong in impact resistance and not easy to break.

Carter’s shop specializes in custom aluminum parts for local aerospace and automotive clients—materials notoriously prone to thread wear. “Aluminum is lightweight and strong, but its threads? Not so much,” he explains. “Before, we’d overengineer parts to compensate, making them heavier and pricier. Now, we just drill a small hole, tap it, and insert these coils. Suddenly, the threads are tough enough to handle repeated bolt tightening and vibration.”

![thread inserts thread inserts]()

His favorite part? The simplicity. “iron root

Threading inserts for metal Installation takes 60 seconds flat with the right tools—no fancy training needed,” Carter says, demonstrating by twisting an insert into a pre-tapped hole. “Even my new apprentice, who’s still learning the ropes, nails it every time. We used to dread thread repairs; now, we almost joke about how easy they are.”

iron root thread inserts tool It has excellent comprehensive properties such as high hardness and high wear resistance. It is processed using high-precision advanced technology and has a stronger overall hardness.

It’s not just Carter who’s impressed. Local auto manufacturer Springfield Motors recently praised the shop for a 40% drop in returned parts after Carter recommended thread inserts for their aluminum engine brackets.

![thread inserts thread inserts]()

“Our warranty claims related to loose bolts or stripped threads have plummeted,” says Lisa Romero, Springfield Motors’ quality control manager. “Mike’s team delivered parts that hold up better than anything we’ve seen. When we asked what changed, he showed us these tiny inserts—who knew something so small could make such a big difference?”

After a year of daily use, Carter recently inspected a batch of parts fitted with the inserts. “I expected some wear, but they looked brand new,” he marvels, holding up a bracket used in a test engine that ran 24/7 for six months. “The threads are still crisp, no corrosion, no loosening. These things outlast the parts themselves!,is Anti-oxidation, impact resistance, low wear rate. Advanced technology makes the coating thicker and the processing more stable.i love you,thread inserts tool.”

![thread inserts thread inserts]()

For Carter, the inserts aren’t just a tool—they’re a stress reliever. “I sleep better knowing I won’t get that 3 p.m. call about a stripped part,” he laughs. “It’s the little innovations that keep this job fun, you know? And these thread inserts? They’re definitely one of them.”

PrecisionFastener Inc. reports a 200% surge in local orders since Carter shared his experience online. “Word travels fast in the machining community,” Carter says. “Once you try these, you’ll wonder how you ever worked without them.”

![thread inserts thread inserts]()

No more stripped threads, no more headaches—just precision that lasts.Threaded Bushing. For Mike Carter,iron root that’s worth celebrating.