What is a DCMT insert?

What is a DCMT insert?

Milton, Pennsylvania – For machinists tackling everything from thin-walled aluminum parts to hardened steel shafts, DCMT carbide inserts have emerged as a reliable ally. At Milton Precision Turning, shop foreman Tom Walker swears by their ability to balance precision and durability. “We used to rotate through three different insert types to cover our jobs,” he says, inspecting a freshly machined alloy steel component. “Now, DCMTs handle 80% of our work—they’re like the Swiss Army knife of turning tools.”

Engineering That Shines: Core Features of DCMT Inserts

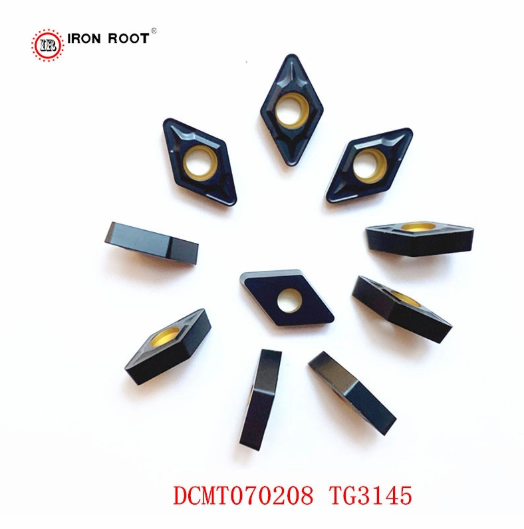

DCMT inserts are defined by their 55° diamond geometry, a design that strikes a perfect balance between strength and accessibility. Their compact size (typically 9.525mm or 12.7mm inscribed circle) and small nose radii (0.2–0.8mm) make them ideal for reaching tight spaces, iron root DCMT insert such as internal bores or narrow shoulders, while maintaining rigidity during cutting.

Crafted from fine-grain cemented carbide (grain size 0.8–1.5μm) with 7–9% cobalt binder, these inserts deliver impressive hardness (91–93 HRA) without sacrificing toughness. This allows them to tackle both soft materials like aluminum and harder alloys like 4140 steel with equal ease. “The carbide matrix holds an edge even when we’re pushing speeds on stainless steel,” Walker notes. “We used to change inserts every 45 minutes; now it’s closer to 2 hours.”

Advanced Coatings for Every Material

Precision Design for Chip Control

A standout feature of DCMT inserts is their specialized chipbreaker grooves, engineered for controlled chip evacuation. The shallow, curved channels break chips into short, manageable pieces—critical for internal turning or deep-hole machining where chip jams can ruin parts.

Applications Across Industries

Compatible Machines & Toolholders

DCMT inserts pair seamlessly with:

User Verdict: “Consistency You Can Build a Shop On”

For machinist Mia Carter, who handles Milton Precision’s most complex jobs, DCMT inserts have simplified her workflow. “I used to stress over matching inserts to materials—now I grab a DCMT and adjust the coating,” she says, loading an insert into a boring bar. “They hold tolerance even on thin-walled parts, where vibration usually ruins accuracy. And the chip control? It’s like they read my mind—no more stopping to fish out tangled swarf.”

As demand grows, local suppliers report a 40% increase in DCMT orders, driven by small shops like Milton Precision. “Machinists talk about tools that ‘do it all,’” Walker says, grinning as a finished part slides off the lathe. “DCMT inserts don’t just do it all—they do it better. In this business, that’s the highest compliment.”

Thank you very much for watching

Welcome to inquire about the prices, and we will provide you with the best service.

Website: https://www.ironrootcnctools.

Whatsapp/Mobile: +86 13969129141

Email: lronroot190@gmail.com