What is a DNMG insert used for?

What is a DNMG insert used for?

Forget one-trick tools—your CNC lathe’s new best friend has arrived. A global leader in machining solutions just dropped a range of DNMG carbide turning inserts that’s basically the “Swiss Army Knife” of precision cutting: tough enough for steel, smooth enough for aluminum, and smart enough to slash downtime like a pro.

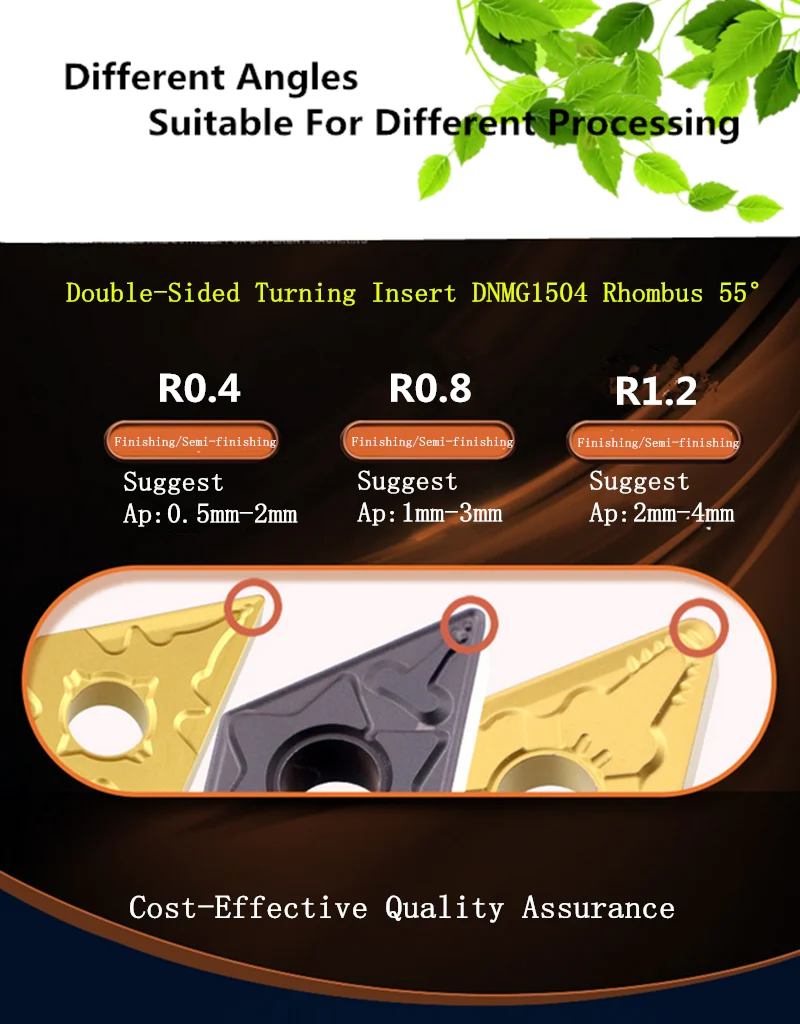

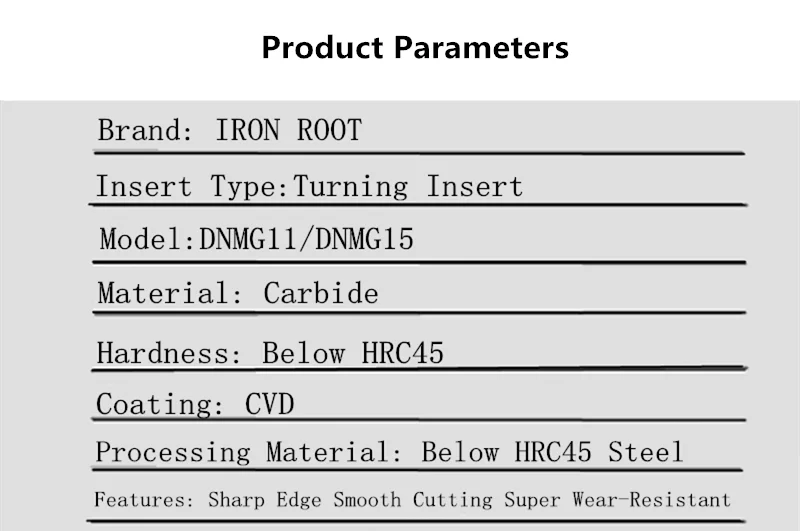

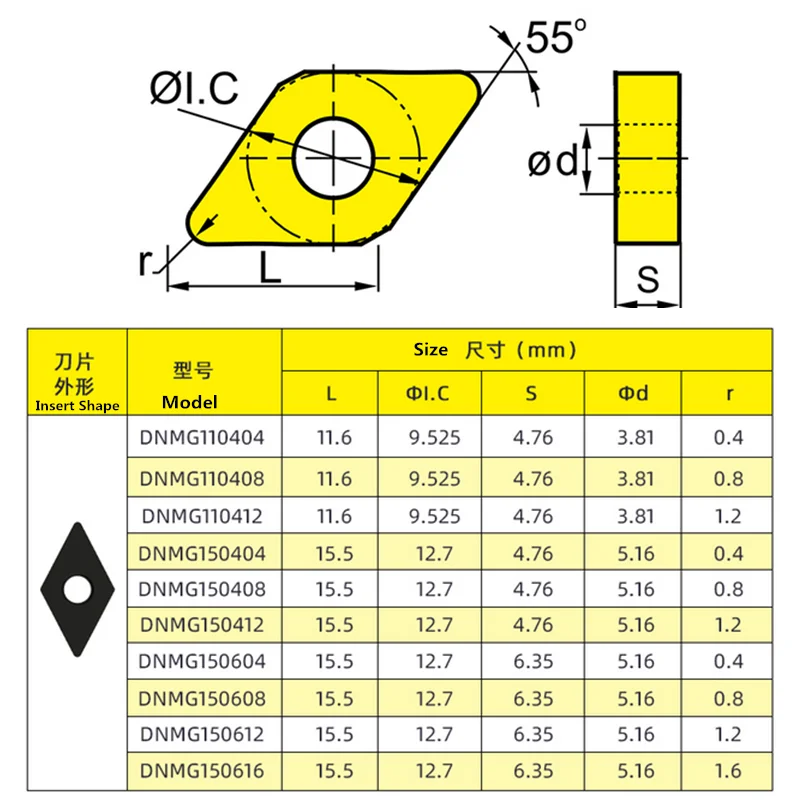

Let’s break down why this little diamond-shaped powerhouse (yes, it’s a 55° diamond—think “strength meets finesse”) is causing a buzz. It’s not just another insert; it’s a rule-breaker. Carbide Insert The ironroot DNMG design hits that sweet spot between “I need to rough-cut this steel like it owes me money” and “I need this aluminum part to shine like a new smartphone.” With specs like 15mm length, 4.76mm thickness, and nose radii from 0.4–1.2mm, it’s compatible with almost every standard CNC tool holder (MTGNR, SCLCR—you name it) so you won’t be stuck hunting for special adapters.

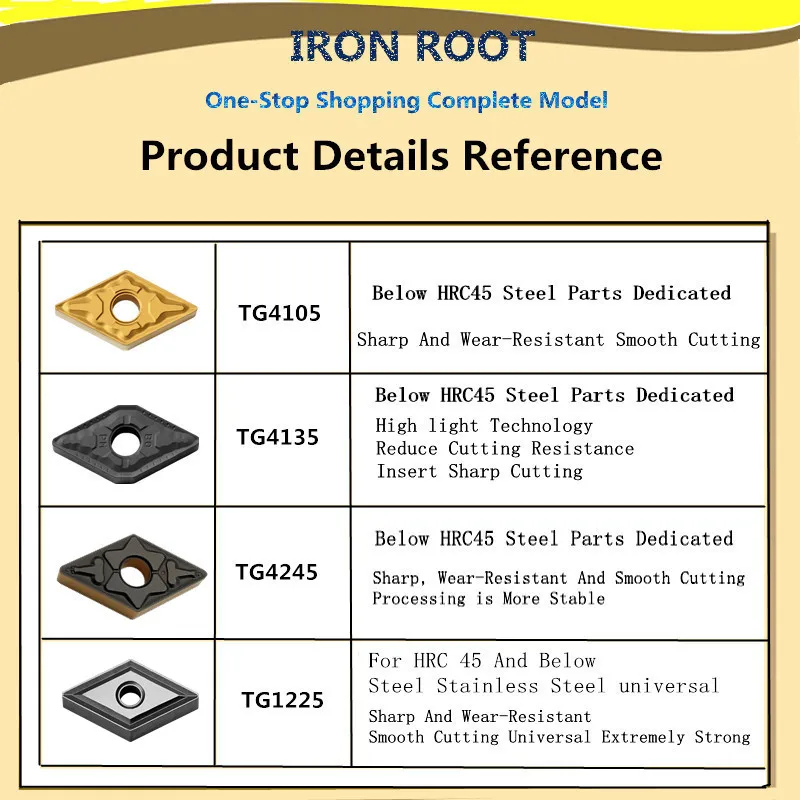

But here’s where it gets juicy: it’s a chameleon for materials. Got steel? cnc tools Grab the TG-grade version—it laughs at high temperatures and wears like iron. Aluminum giving you grief with sticky chips? The K10-grade “-AL” model kicks built-up edge (BUE) to the curb, leaving finishes so smooth you could almost use them as mirrors. Stainless steel being a diva? LF6018-grade inserts outsmart its work-hardening tricks, no drama.

And let’s talk about the money-saving magic: this insert is indexable, ironroot DNMG inserts meaning it’s got 4 usable cutting edges. dnmg tool Think of it like a pencil—when one end gets dull, you flip it. No regrinding, no waiting around.

“We used to change tools every hour for steel shaft jobs,” says Mark Williams, a CNC lathes Supervisor at a top automotive parts shop. “Now? We flip the DNMG insert and keep going—tool changes are down 50%, and we’re hitting ±0.01mm tolerances like clockwork. The surface finish? Ra 1.6μm—so good we skipped a whole post-processing step. It’s like our lathe just got a promotion. My team used to groan about tool change delays; now they’re actually excited to run the steel line—who would’ve thought an insert could do that?”

Even precision-focused industries are singing its praises. “We make tiny medical fasteners that need to be perfect—no room for error,” explains Raj Patel, a manufacturing engineer at a medical device firm. “We tried three other inserts before DNMG, and none could handle stainless steel without messing up tolerances. The LF6018-grade DNMG? It glides through stainless like it’s butter, and the consistency? We haven’t had a rejected part since we switched. My quality team is thrilled—less checking, more producing.”

Curious how this diamond-shaped dynamo can level up your shop? Head to the manufacturer’s website or hit up their tech team—your CNC lathe (and your bottom line) will thank you.

Thank you very much for watching

Welcome to inquire about the prices, and we will provide you with the best service.

Website: https://www.ironrootcnctools.

Whatsapp/Mobile: +86 13969129141

Email: lronroot190@gmail.com