CNMG 433 insert

The CNMG inserts for lathes offer several key advantages that enhance machining efficiency and precision:

1. High Strength and Durability

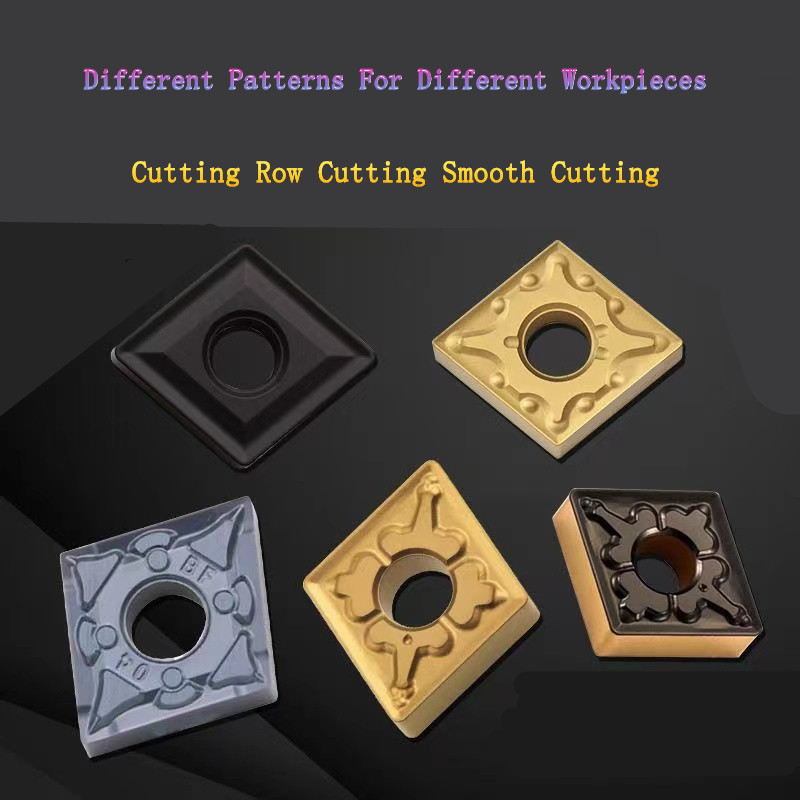

2. lmproved Chip Control and Evacuation

3. Versatility in Applications

4. Cost-Effectiveness

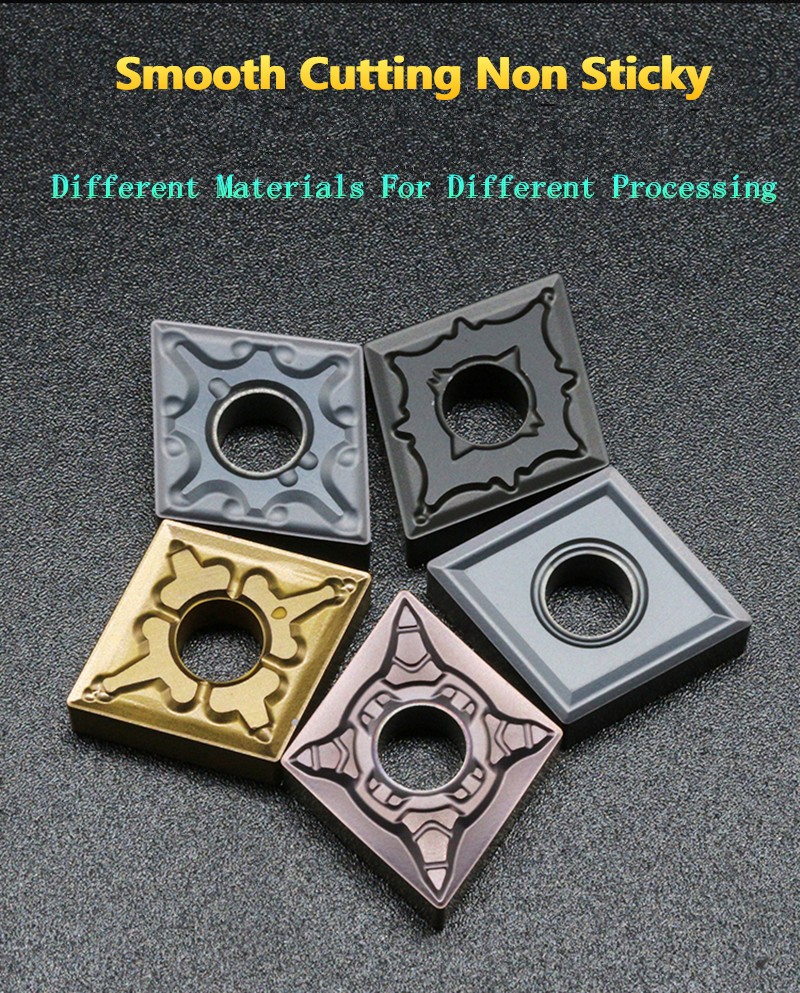

5. Enhanced Surface Finish

6.Advanced Coating Technologies.

Overall, CNMG inserts are designed to optimize efficiency, precision, and tool life in lathe operations, making them a reliable choice for various machining needs.

When it comes to optimizing lathe operations, insert tools play a crucial role in enhancing efficiency and precision. Among the standout options are the CNMG 433 insert and CNMG 1204 04 inserts, both designed to deliver exceptional performance tailored to specific machining needs.Firstly, the CNMG 433 insert is engineered with a robust geometry that provides superior strength and stability. Its 80° diamond shape ensures a high degree of rigidity, making it ideal for heavy-duty cutting tasks and demanding machining conditions. This insert tool for lathe is particularly effective in handling tough materials such as steel and stainless steel, offering excellent resistance to wear and deformation. Advanced coating technologies further enhance its durability and heat resistance, allowing for higher cutting speeds and longer tool life

.

Secondly, the CNMG 1204 04 inserts are designed to optimize efficiency and precision in a wide range of lathe operations. Their unique geometry ensures smooth chip flow and reduced cutting forces, resulting in improved surface finishes and reduced tool wear. These inserts are versatile, suitable for both roughing and finishing tasks, and provide excellent edge strength and resistance to thermal cracking.

When it comes to precision machining and efficiency, insert tools for lathe are essential components that can significantly enhance your manufacturing process. Among the top choices are the CNMG 433 insert and CNMG 1204 04 inserts, both designed to deliver exceptional performance and reliability.

The CNMG 433 insert is renowned for its robust construction and versatility. Its 80° diamond shape provides superior strength and stability, making it ideal for heavy-duty cutting operations. This insert tool for lathe excels in handling tough materials such as steel and stainless steel, offering excellent resistance to wear and deformation.

The CNMG 433 insert also features advanced coating technologies that enhance its durability and heat resistance, allowing for higher cutting speeds and longer tool life.

Their unique geometry ensures smooth chip flow and reduced cutting forces, resulting in improved surface finishes and reduced tool wear. The CNMG 1204 04 inserts also benefit from advanced material science, providing excellent edge strength and resistance to thermal cracking.