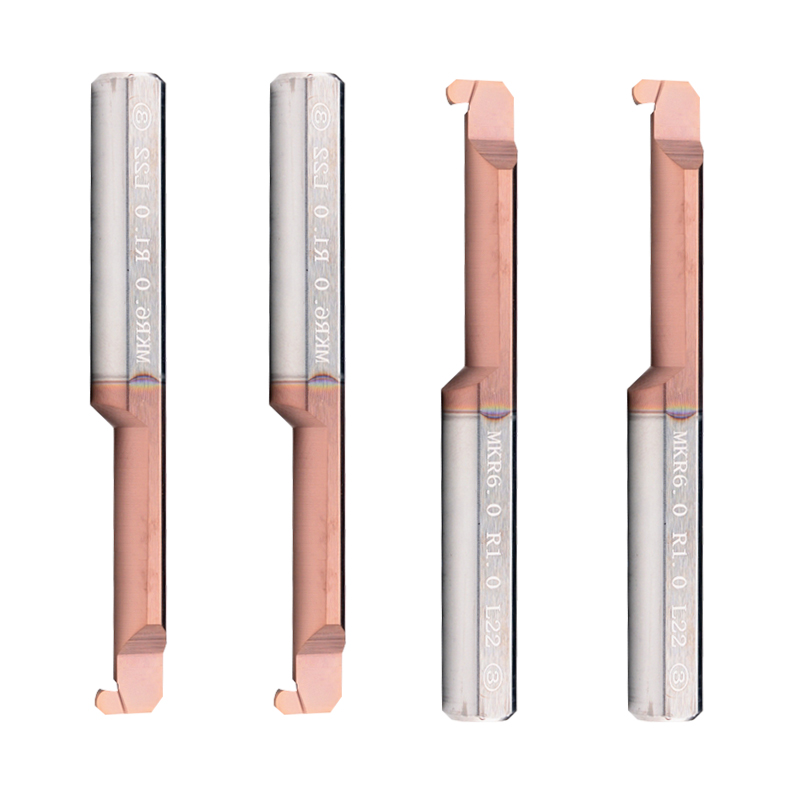

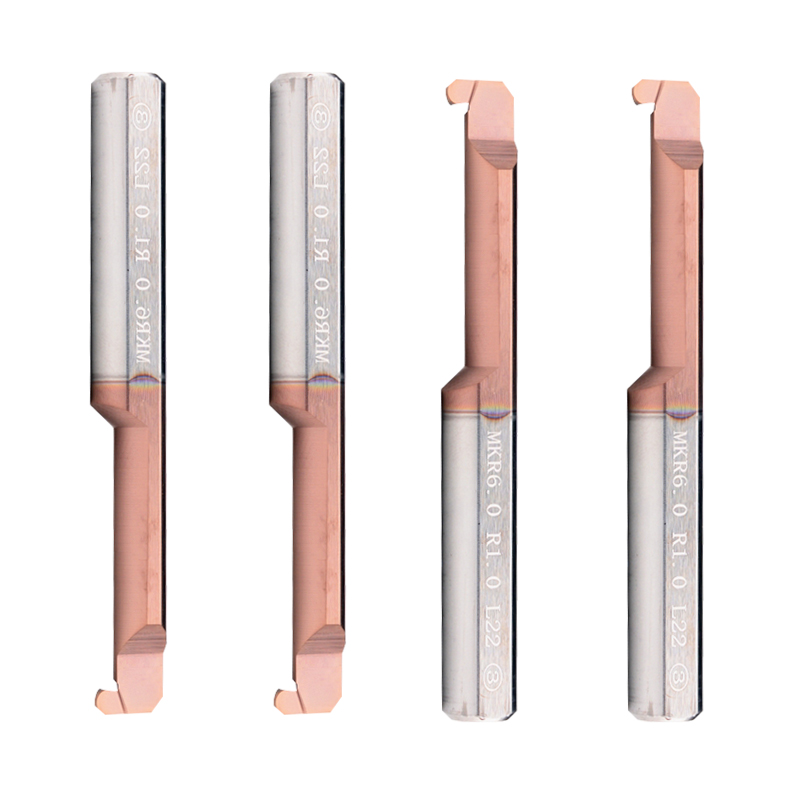

MKR series tungsten steel anti-vibration small hole boring cutter overall alloy coating boring bar suitable for lathe

High-quality materials

DMIX tungsten steel: The MKR series of small hole boring cutters are made of DMIX tungsten steel, which has extremely high hardness and excellent wear resistance. It can effectively resist wear during long-term processing, thereby extending the service life of the tool.High-performance alloy: Some MKR series tools are made of high-performance alloy materials, which are not only hard and wear-resistant, but also have good toughness, avoiding the problem of fragility of traditional carbide tools, making the processing process more stable.

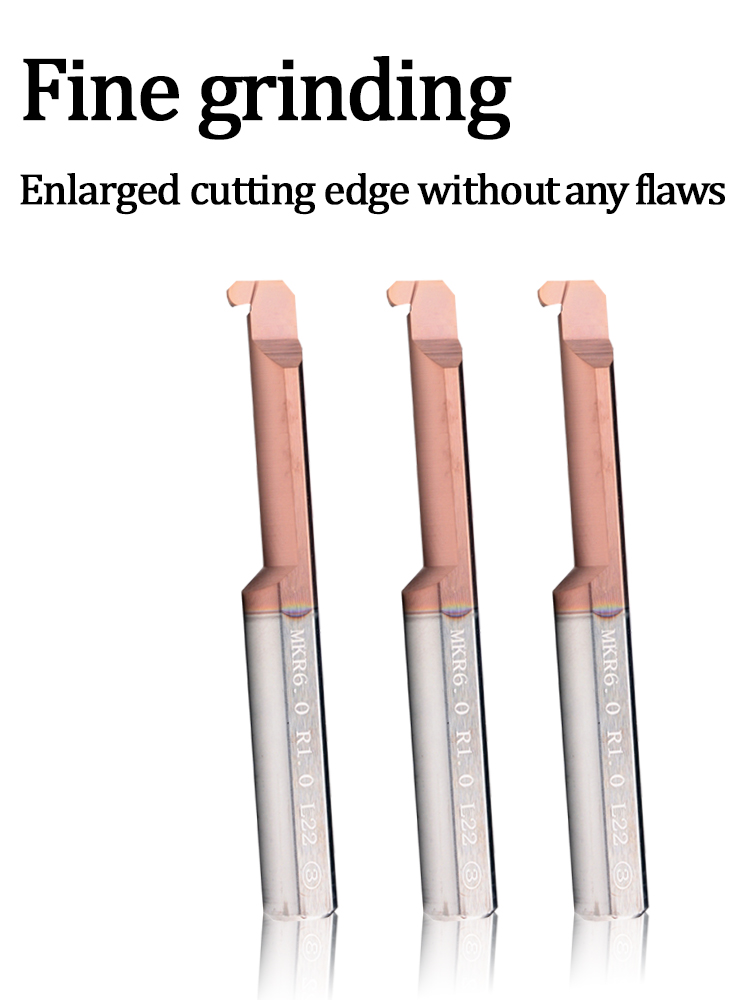

Unique design

Geometry and edge treatment: The cutting edge of the MKR series small hole boring cutter has a unique geometry, such as a 98-degree rake angle design, which allows a single geometry to be used in multiple applications, including boring, profiling and chamfering. In addition, the cutting edge of the tool is finely ground to ensure extremely high precision, ensuring that the machined parts meet strict quality standards.

Internal coolant design: Some MKR series tools are equipped with through-type internal coolant holes. This feature allows the coolant jet to be precisely directed to the optimal position of the cutting point, thereby improving tool life and chip control.

High precision

Dimensional stability: During the processing, the MKR series small hole boring cutters can maintain good dimensional stability, with no vibration in the roughing and finishing process, and small changes in the upper and lower aperture sizes. For example, in the test, the upper and lower aperture sizes changed by about 0.005.

High processing accuracy: This series of tools can ensure that the processed parts have a smooth surface and accurate dimensions, meeting the requirements of high-precision processing.

The MKR series of small hole boring cutters has many outstanding advantages. First of all, it uses high-quality DMIX tungsten steel and high-performance alloy materials to ensure the high hardness, wear resistance and good toughness of the tool, effectively extending the service life. Secondly, in terms of design, its cutting edge has a unique geometric shape, combined with fine edge grinding, to ensure extremely high processing accuracy and surface quality; some products are also equipped with internal cooling design, which further improves the tool life and chip control ability. In addition, this series of tools shows good dimensional stability during the processing process and can meet the needs of high-precision processing. In terms of applicability, it can not only be used for the processing of inner holes and small holes, but also for the cutting task of arc R grooves. It is suitable for a variety of materials and different industries, and has strong versatility. Finally, its installation and commissioning are quick, and there are detailed operating instructions, which is very convenient to use.

| D | MKR 系列 | L | L1 | H/Grooving depth | Minimum aperture |

| 4 | D4-MKR 4 R0.5 L10 | 50 | 10 | 1 | 4.1 |

| D4-MKR 4 R0.75 L10 | 50 | 10 | 1 | 4.1 | |

| 5 | D5-MKR 5 R0.5 L15 | 50 | 15 | 1.2 | 5.1 |

| D5-MKR 5 R0.75 L15 | 50 | 15 | 1.2 | 5.1 | |

| D5-MKR 5 R1.0 L15 | 50 | 15 | 1.2 | 5.1 | |

| 6 | D6-MKR 6 R0.5 L15 | 50 | 15 | 1.6 | 6.1 |

| D6-MKR 6 R0.5 L22 | 50 | 22 | 1.6 | 6.1 | |

| D6-MKR 6 R0.75 L15 | 50 | 15 | 1.6 | 6.1 | |

| D6-MKR 6 R0.75 L22 | 50 | 22 | 1.6 | 6.1 | |

| D6-MKR 6 R1.0 L15 | 50 | 15 | 1.6 | 6.1 | |

| D6-MKR 6 R1.0 L22 | 50 | 22 | 1.6 | 6.1 |

Wide applicability

Multi-purpose: MKR series small hole boring cutters are not only suitable for processing inner holes and small holes, but also for cutting arc R grooves, and can easily handle workpieces of different shapes and sizes.

Applicable to a variety of materials: Suitable for processing a variety of materials such as pig iron, cast iron, 45# steel, abrasive steel, etc.

Multi-industry application: In many industries such as automobile manufacturing, aerospace, electronics industry, precision instruments, etc., MKR series small hole boring cutters can play their excellent performance and help improve processing efficiency and product quality.