MGR series tungsten steel small hole grooving tool 0.3-4mm precision grooving carbide multi-edge boring tool

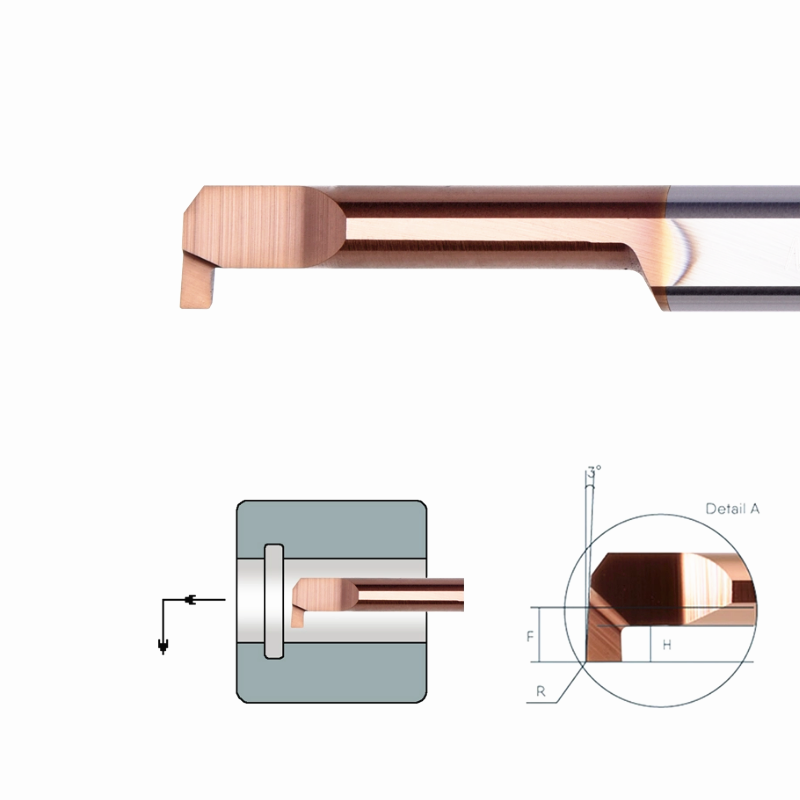

Material and Process

Using high-quality tungsten steel alloy or cemented carbide material, the hardness can reach HRA92 or above, and the wear resistance and impact resistance are significantly better than ordinary high-speed steel.

Special surface coating treatment (such as nano blue coating) further reduces the friction coefficient and extends the tool life to 3-5 times that of ordinary tools.

Anti-vibration tool bar technology: The built-in shock-absorbing structure can reduce the vibration amplitude by 50%, ensuring that the aperture tolerance is controlled within ±0.005mm.

Modular tool head: supports rapid replacement of 1-10mm diameter range to meet different working conditions.

Precision machinery field

Aerospace: Processing of fuel nozzle micropores (minimum aperture 0.8mm.

Medical equipment: Finishing of titanium alloy artificial joint inner holes (surface roughness Ra≤0.4μm.

Challenges of complex working conditions

Processing of stainless steel 304 material: cutting speed can reach 120m/min, and chip breaking effect is excellent.

45° blind hole expansion: The taper design of the tool body ensures processing stability and avoids tool tip breakage.

Industrial Revolution of Micro-hole Processing

In the field of precision manufacturing, micro-hole processing with a hole diameter less than 10mm has long faced three major pain points: short tool life, low dimensional accuracy, and poor material adaptability. When traditional high-speed steel tools process titanium alloys, the life of a single blade is less than 200 pieces; and the processing yield rate of difficult-to-cut materials such as hardened steel is even lower than 80%. The birth of the MFR series of small hole boring tools has pushed micro-hole processing into a new era of "nano-level precision + thousand-piece life" through the dual breakthroughs of material science and structural mechanics.

| D | MGR series | L | L1 | H/Grooving depth | Minimum aperture |

| 3 | D3-MGR 3 B0.3 L10 | 50 | 10 | 0.6 | 3.1 |

| D3-MGR 3 B0.5 L10 | 50 | 10 | 0.6 | 3.1 | |

| D3-MGR 3 B0.7 L10 | 50 | 10 | 0.6 | 3.1 | |

| D3-MGR 3 B0.75 L10 | 50 | 10 | 0.6 | 3.1 | |

| D3-MGR 3 B1.0 L10 | 50 | 10 | 0.6 | 3.1 | |

| D3-MGR 3 B1.5 L10 | 50 | 10 | 0.6 | 3.1 | |

| 4 | D4-MGR 3 B0.3 L10 | 50 | 10 | 0.6 | 3.1 |

| D4-MGR 3 B0.5 L10 | 50 | 10 | 0.6 | 3.1 | |

| D4-MGR 3 B0.7 L10 | 50 | 10 | 0.6 | 3.1 | |

| D4-MGR 3 B0.75 L10 | 50 | 10 | 0.6 | 3.1 | |

| D4-MGR 3 B1.0 L10 | 50 | 10 | 0.6 | 3.1 | |

| D4-MGR 3 B1.5 L10 | 50 | 10 | 0.6 | 3.1 | |

| D4-MGR 4 B0.3 L10 | 50 | 10 | 1 | 4.1 | |

| D4-MGR 4 B0.3 L15 | 50 | 15 | 1 | 4.1 | |

| D4-MGR 4 B0.5 L10 | 50 | 10 | 1 | 4.1 | |

| D4-MGR 4 B0.5 L15 | 50 | 15 | 1 | 4.1 | |

| D4-MGR 4 B0.7 L10 | 50 | 10 | 1.0 | 4.1 | |

| D4-MGR 4 B0.8 L10 | 50 | 10 | 1.0 | 4.1 | |

| D4-MGR 4 B1.0 L10 | 50 | 10 | 1.0 | 4.1 | |

| D4-MGR 4 B1.0 L15 | 50 | 15 | 1.0 | 4.1 | |

| D4-MGR 4 B1.2 L10 | 50 | 10 | 1.0 | 4.1 | |

| D4-MGR 4 B1.2 L15 | 50 | 15 | 1.0 | 4.1 | |

| D4-MGR 4 B1.5 L10 | 50 | 10 | 1.0 | 4.1 | |

| D4-MGR 4 B1.5 L15 | 50 | 15 | 1.0 | 4.1 | |

| D4-MGR 4 B2.0 L10 | 50 | 10 | 1.0 | 4.1 | |

| D4-MGR 4 B2.0 L15 | 50 | 15 | 1.0 | 4.1 | |

| 5 | D5-MGR 5 B0.75 L15 | 50 | 15 | 1.2 | 5.1 |

| D5-MGR 5 B0.75 L22 | 50 | 22 | 1.2 | 5.1 | |

| D5-MGR 5 B1.0 L15 | 50 | 15 | 1.2 | 5.1 | |

| D5-MGR 5 B1.0 L22 | 50 | 22 | 1.2 | 5.1 | |

| D5-MGR 5 B1.2 L10 | 50 | 10 | 1.2 | 5.1 | |

| D5-MGR 5 B1.2 L15 | 50 | 15 | 1.2 | 5.1 | |

| D5-MGR 5 B1.2 L22 | 50 | 22 | 1.2 | 5.1 | |

| D5-MGR 5 B1.5 L15 | 50 | 15 | 1.2 | 5.1 | |

| D5-MGR 5 B1.5 L22 | 50 | 22 | 1.2 | 5.1 | |

| D5-MGR 5 B2.0 L15 | 50 | 15 | 1.2 | 5.1 | |

| D5-MGR 5 B2.0 L22 | 50 | 22 | 1.2 | 5.1 | |

| 6 | D6-MGR 5 B0.75 L15 | 50 | 15 | 1.2 | 5.1 |

| D6-MGR 5 B0.75 L22 | 50 | 22 | 1.2 | 5.1 | |

| D6-MGR 5 B1.0 L15 | 50 | 15 | 1.2 | 5.1 | |

| D6-MGR 5 B1.0 L22 | 50 | 22 | 1.2 | 5.1 | |

| D6-MGR 5 B1.2 L10 | 50 | 10 | 1.2 | 5.1 | |

| D6-MGR 5 B1.2 L15 | 50 | 15 | 1.2 | 5.1 | |

| D6-MGR 5 B1.2 L22 | 50 | 22 | 1.2 | 5.1 | |

| D6-MGR 5 B1.5 L15 | 50 | 15 | 1.2 | 5.1 | |

| D6-MGR 5 B1.5 L22 | 50 | 22 | 1.2 | 5.1 | |

| D6-MGR 5 B2.0 L15 | 50 | 15 | 1.2 | 5.1 | |

| D6-MGR 5 B2.0 L22 | 50 | 22 | 1.2 | 5.1 | |

| D6-MGR 6 B0.5 L15 | 50 | 15 | 1.4 | 6.1 | |

| D6-MGR 6 B0.5 L22 | 50 | 22 | 1.4 | 6.1 | |

| D6-MGR 6 B0.75 L15 | 50 | 15 | 1.4 | 6.1 | |

| D6-MGR 6 B0.75 L22 | 50 | 22 | 1.4 | 6.1 | |

| D6-MGR 6 B1.0 L15 | 50 | 15 | 1.4 | 6.1 | |

| D6-MGR 6 B1.0 L22 | 50 | 22 | 1.4 | 6.1 | |

| D6-MGR 6 B1.2 L15 | 50 | 15 | 1.4 | 6.1 | |

| D6-MGR 6 B1.2 L22 | 50 | 22 | 1.4 | 6.1 | |

| D6-MGR 6 B1.5 L15 | 50 | 15 | 1.4 | 6.1 | |

| D6-MGR 6 B1.5 L22 | 50 | 22 | 1.4 | 6.1 | |

| D6-MGR 6 B2.0 L10 | 50 | 10 | 1.4 | 6.1 | |

| D6-MGR 6 B2.0 L15 | 50 | 15 | 1.4 | 6.1 | |

| D6-MGR 6 B2.0 L22 | 50 | 22 | 1.4 | 6.1 | |

| D6-MGR 6 B2.5 L15 | 50 | 15 | 1.4 | 6.1 | |

| D6-MGR 6 B2.5 L22 | 50 | 22 | 1.4 | 6.1 | |

| D6-MGR 6 B3.0 L15 | 50 | 15 | 1.4 | 6.1 | |

| D6-MGR 6 B3.0 L22 | 50 | 22 | 1.4 | 6.1 | |

| 8 | D8-MGR 8 B1.0 L22 | 60 | 22 | 1.7 | 8.1 |

| D8-MGR 8 B1.0 L30 | 60 | 30 | 1.7 | 8.1 | |

| D8-MGR 8 B1.5 L22 | 60 | 22 | 1.7 | 8.1 | |

| D8-MGR 8 B1.5 L30 | 60 | 30 | 1.7 | 8.1 | |

| D8-MGR 8 B2.0 L22 | 60 | 22 | 1.7 | 8.1 | |

| D8-MGR 8 B2.0 L30 | 60 | 30 | 1.7 | 8.1 | |

| D8-MGR 8 B2.5 L22 | 60 | 22 | 2.6 | 8.1 | |

| D8-MGR 8 B3.0 L22 | 60 | 22 | 2.6 | 8.1 |

The MFR series small hole boring tool is not only a tool, but also a cross-border integration of material science, precision machinery and digital technology. In the process of transition from Industry 4.0 to 5.0, it redefines the possibility of micro-hole processing with "nano-level precision, military-level reliability, and mass production-level cost", and has become a model of domestic substitution in the field of high-end manufacturing.