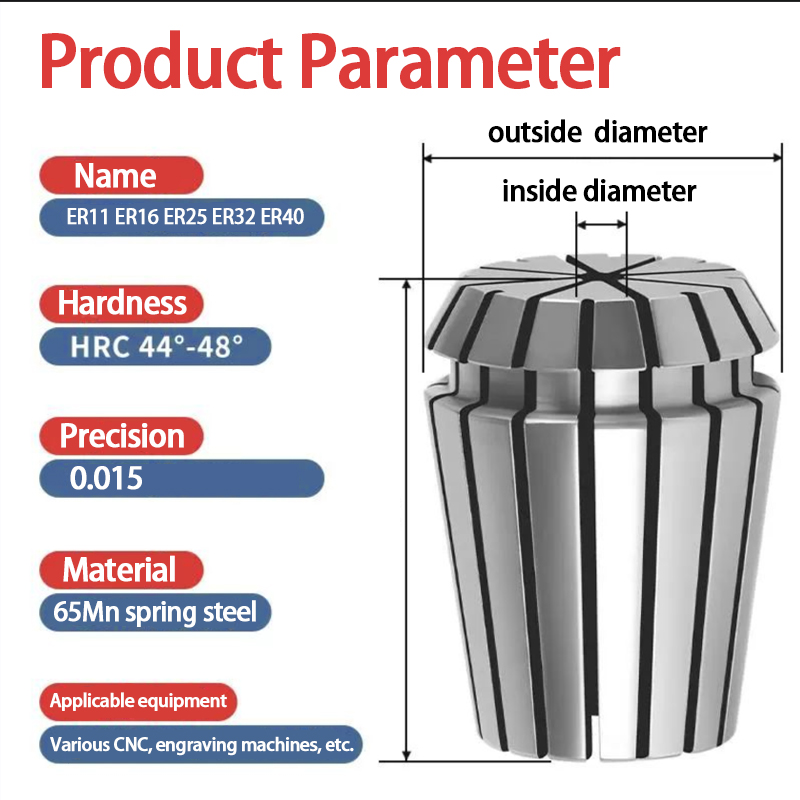

ER25 AA high precision 0.005mm spring collet, suitable for engraving machine spindle, CNC machining center

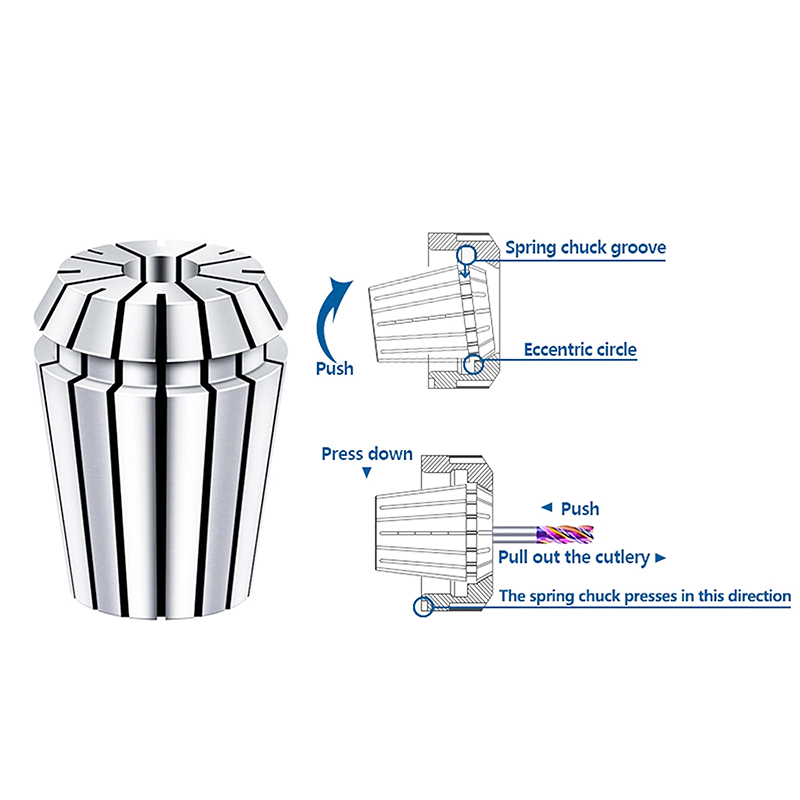

Result Principle

ER chucks are usually composed of a sleeve and a nut. The sleeve is conical, and there are evenly distributed elastic grooves on its outer circumference. When the nut is tightened, the sleeve is subjected to axial force, and the conical surface is compressed, so that the inner diameter of the sleeve shrinks, tightly holding the tool to achieve tool clamping. This structure can provide high-precision tool positioning and stable clamping force.

Features

1. High precision: The manufacturing precision of ER chucks is high, which can ensure that the radial runout of the tool is within a very small range, generally reaching ±0.01mm or even higher, thereby improving the processing accuracy and is suitable for occasions with high requirements for processing accuracy.

2. High rigidity: It can provide a large clamping force, so that the tool remains stable during the cutting process, reduces vibration and deformation, is conducive to improving processing efficiency and surface quality, and can also extend the service life of the tool.

3. Good compatibility: ER chucks have a variety of specifications and sizes, which can be adapted to tools of different diameters. The common clamping range ranges from 1mm to 32mm, which can meet a variety of processing needs. In addition, it can be used with various types of tool holders, such as straight handles, tapered handles, etc., and has strong versatility.

4. Quick clamping: The operation is simple and convenient, and the tool can be installed and removed quickly, which reduces the downtime of the machine tool and improves production efficiency.

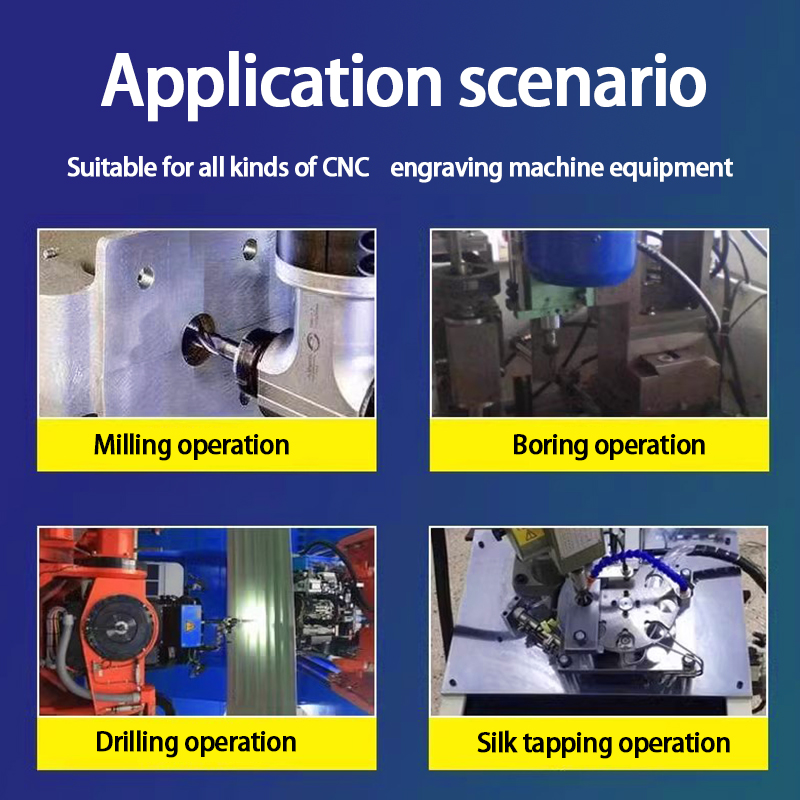

CNC machining center: In CNC milling, drilling and other processing, ER chucks are widely used to clamp various tools, such as end mills, drills, reamers, etc., to achieve high-precision processing.

Lathe: It can be used to clamp turning tools, boring tools and other tools to ensure the stability and accuracy of the tools during the turning process.

EDM: In EDM machine tools, ER chucks are used to clamp electrodes to ensure the positioning accuracy of the electrodes, thereby improving the accuracy and efficiency of EDM.