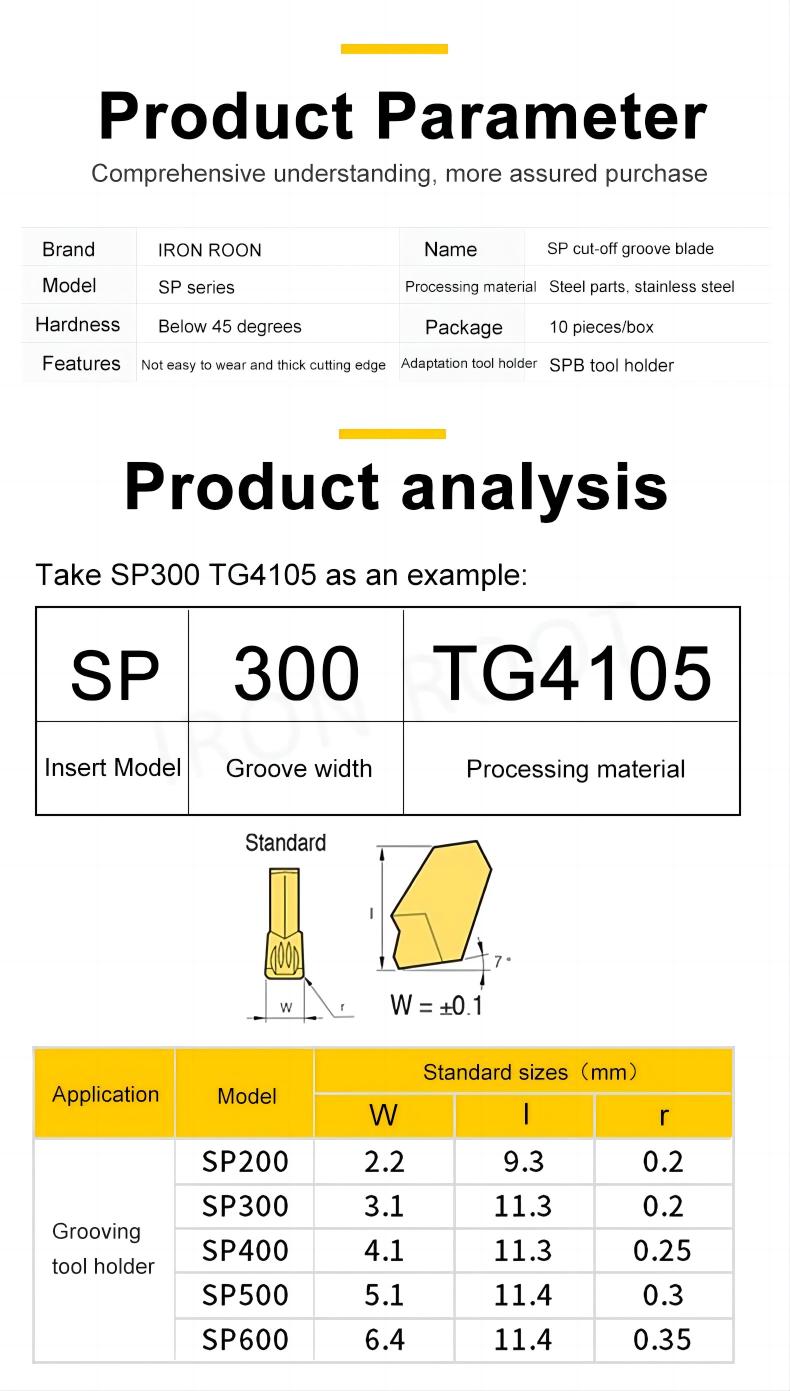

Grooving inserts SP400 TG1225 TG4015 Carbide grooving inserts SP Single head turning grooving inserts

Advantages

1. Material characteristics: It is a material that combines an ultra-fine carbide substrate with a TIAIN PVD coating. This combination of coating and substrate prevents chip accumulation, thereby extending the tool life and ensuring continuous and stable processing.

2. The newly developed TIAIN coating is suitable for high-speed cutting, and has better wear resistance and impact resistance than the usual TIAIN, which improves the stability of cutting and ensures the stability of the blade even in heavy intermittent processing.

3. Structural design: The blade's rake angle is reasonably designed to help increase tool life; the minimum tool tip angle design can remove burrs; various guide angles can achieve the best processing performance; special chip breaker and cutting edge design can obtain the narrowest chips, which is conducive to chip removal and improves the quality of the processing surface.

4. Scope of application: It is a multi-functional cutting tool that can be used for the processing of various workpieces such as alloy steel, cast iron and stainless steel, and is suitable for a variety of processing scenarios.

Processing technology optimization

1. Reasonable selection of processing path: Plan the cutting-in and cutting-out paths of the tool, try to avoid sharp changes in direction or frequent starts and stops of the tool during the cutting process, and reduce the impact on the blade.

2. Make full use of cutting fluid: Select appropriate cutting fluid according to the processing material and processing requirements. When processing materials such as alloy steel and stainless steel with SP400 blades, cutting fluid containing extreme pressure additives can be used to reduce cutting temperature and reduce tool wear. During the processing, ensure that the cutting fluid can be fully poured into the cutting area to play a cooling and lubricating role.

Model:SP200/300/400/500/600 Product Name:Carbide insert

Material:Carbide Application:Metal Cutting

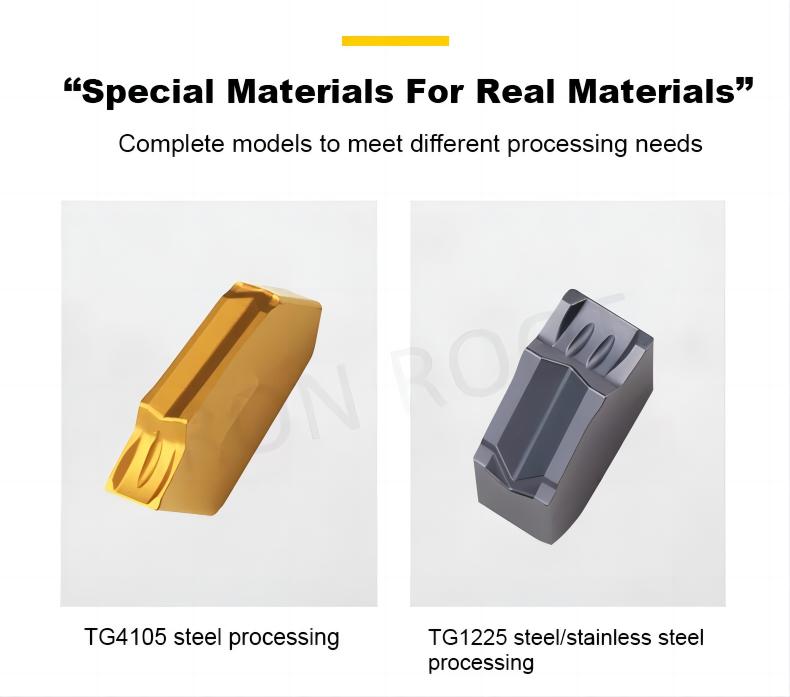

Grade:TG4105 Color:Yellow Hardness:P15-P30 Coating:CVD

This product features a dual-structure alloy substrate that provides enhanced toughness. It is further coated with a medium-thick layer of MT-TiCN and a thick layer of a-AI2O3. This combination makes it well-suited for general intermittent cutting applications on carbon steel and low-alloy steel materials.

Grade:TG1225 Color:Gray Hardness:P20-P35 M20-M35 K20-K35 Coating:PVD

This product is engineered with a microcrystalline carbide substrate that offers optimized wear resistance and toughness. It is paired with a nanocrystalline TiALSiN coating, which boasts high bonding strength. The synergy of these materials results in a broad performance spectrum. It is recommended for general machining processes involving steel and stainless steel.