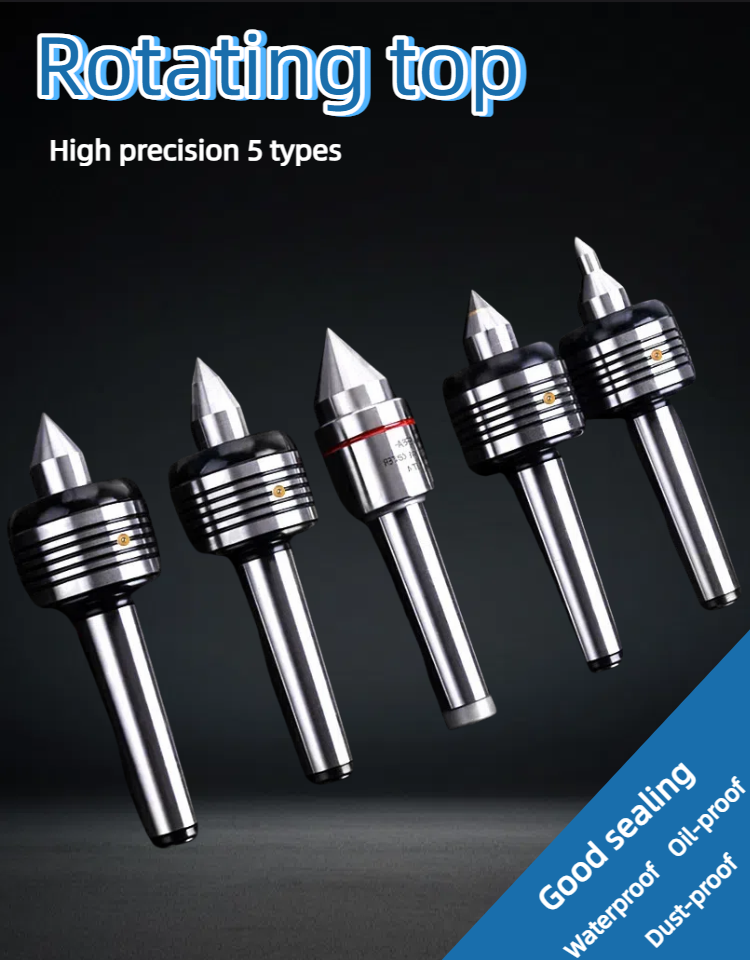

Lathe center double cone rotary movable ejector alloy transition center active Mohs

Purpose:

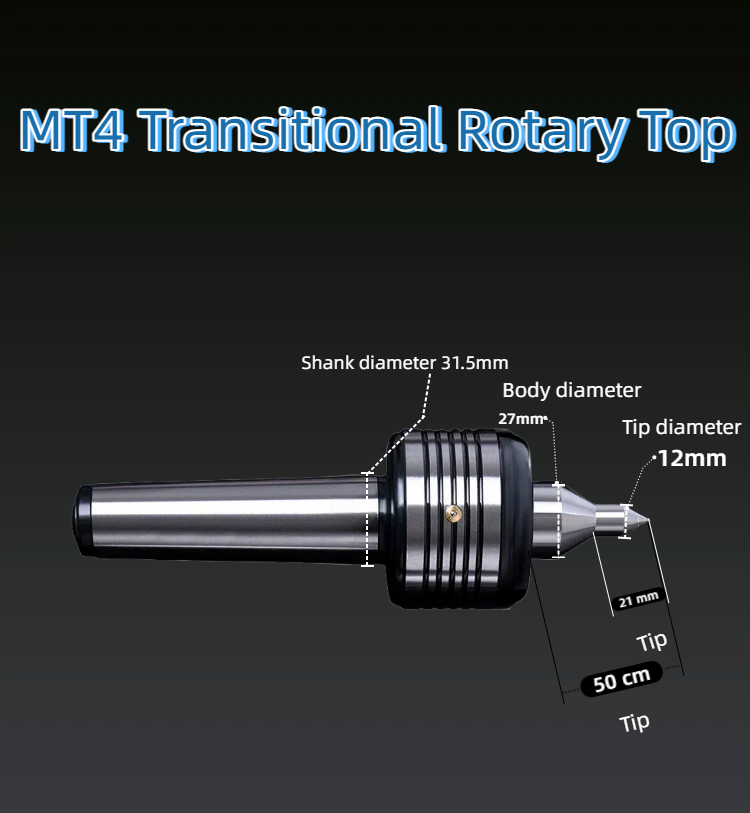

Size conversion and adaptation: When the inner diameter of the workpiece is larger than the size of the universal top of a lathe or other machine tool, it is impossible to clamp and position it directly with the universal top. The transition top can be installed on the universal top to play a transition conversion role, so that the universal top can match the workpiece with a larger inner hole, and realize the clamping and positioning of the workpiece.

Protect the universal top: When processing some special workpieces or performing specific processing operations, the top may be worn or damaged. Using the transition top, it can be installed at the front end of the universal top, so that the transition top can withstand the wear and impact during the processing, thereby protecting the top part of the universal top and extending the service life of the universal top.

Structural features:

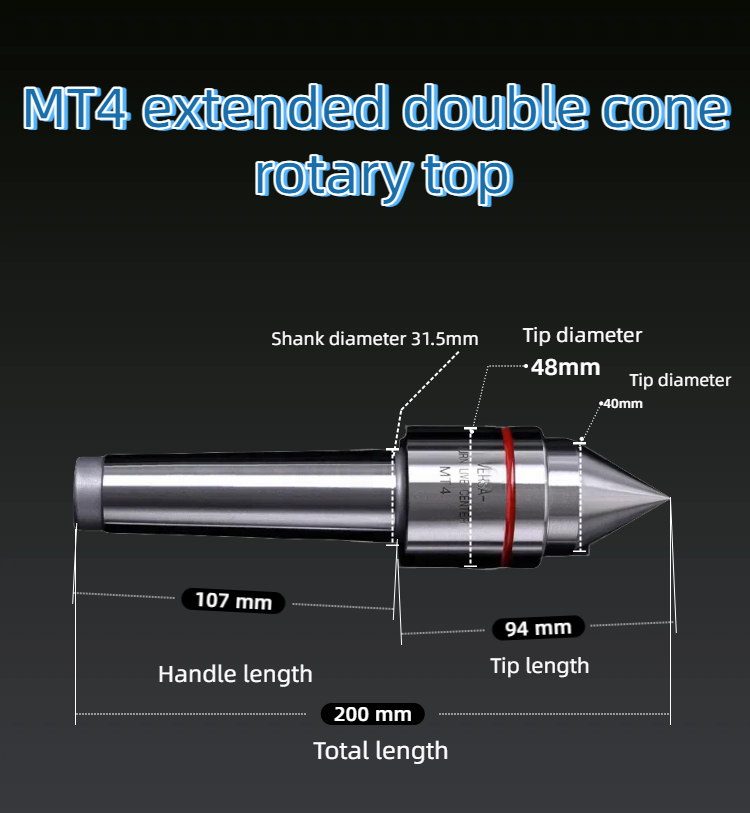

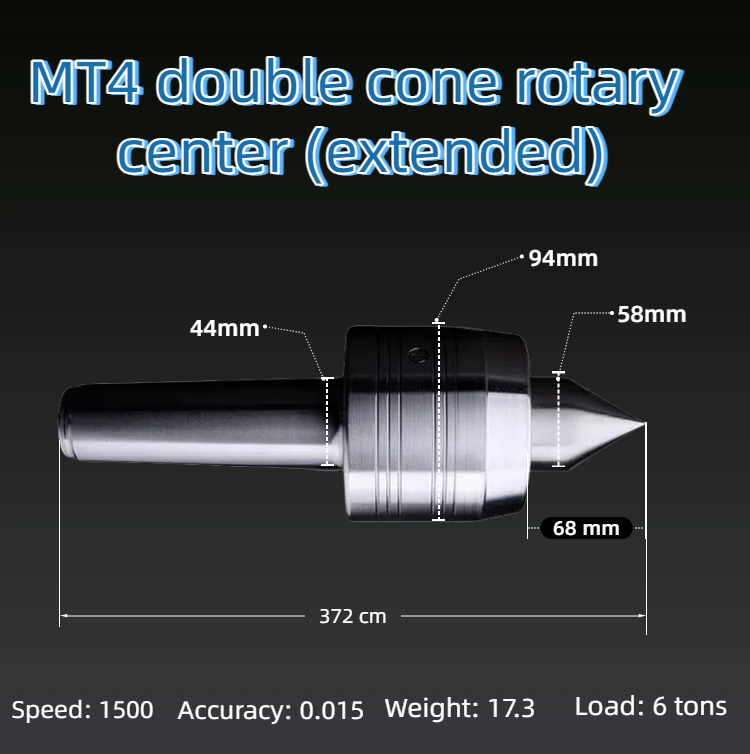

Usually in the shape of a cone, its outer side and the right end face form a certain inclined angle, generally between 45° and 60°, with a through hole on the left and a large hole on the right inside, so as to cooperate with the top part of the universal top for installation.

There are also other transition tips with special structures, such as the expansion-type transition tip hole tooling, which is composed of expansion plugs, expansion sleeves and standard screws. It can be used to clamp parts with deeper light holes or sleeve-like parts in the middle. The expansion plug is used to expand the expansion sleeve to fit the inner hole of the part, ensuring that the center of the tip hole in the middle is consistent with the center of the inner hole of the part.

Light-duty rotary center: Mainly used for machining shaft sleeve parts on small lathes, suitable for high-speed cutting, can achieve high dimensional accuracy of parts with the help of center hole positioning, and is an essential accessory for high-speed cutting on small precision lathes.

Medium-duty rotary center: Used for machining shaft sleeve parts on general lathes, and ensures the dimensional accuracy of parts through center hole positioning.

Heavy-duty elastic rotary center: Suitable for machining shaft sleeve parts on larger lathes, with large load-bearing capacity, can automatically adjust to absorb thermal deformation of workpieces, control thermal stress, and is suitable for high-speed and strong cutting.

Umbrella-shaped rotary center: Mainly used for machining sleeve and tube parts on lathes, can make the machined parts have high dimensional accuracy, suitable for strong cutting.

Insertion rotary center: Used for machining various shaft sleeve parts on lathes, usually with multiple center plugs of different shapes and angles to meet different processing needs.