Umbrella type rotating center for Morse taper shank lathe

Features and application scenarios of large cone angle umbrella-shaped rotary top

Good versatility: The significant advantage of large cone angle umbrella-shaped rotary top (usually with a cone angle of 60°, 75° or 90°) is its versatility. A large cone angle top can adapt to the processing of workpieces with inner hole sizes ranging from tens of millimeters to one or two hundred millimeters. This means that when facing the processing tasks of sleeve parts with a variety of different hole diameters, there is no need to frequently replace the top, which greatly improves the processing efficiency and reduces the tool cost.

Low positioning accuracy: The positioning accuracy of the large cone angle umbrella-shaped rotary top is low. The position error of the outer circle or end face processed by its positioning is large. This is because the contact area between the large cone angle and the inner hole of the workpiece is relatively small, which is easy to cause shaking and offset during the processing process, thereby affecting the processing accuracy. In the processing of parts with high precision requirements,

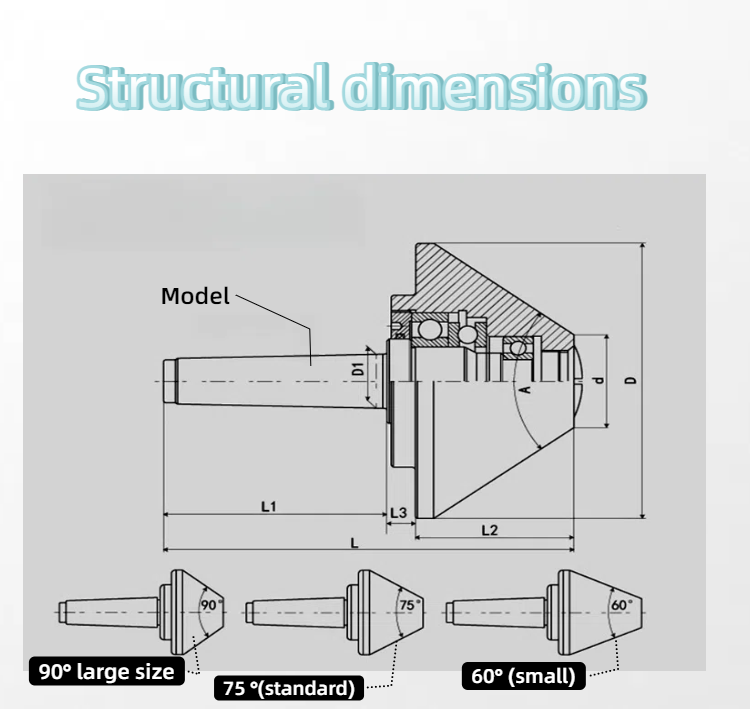

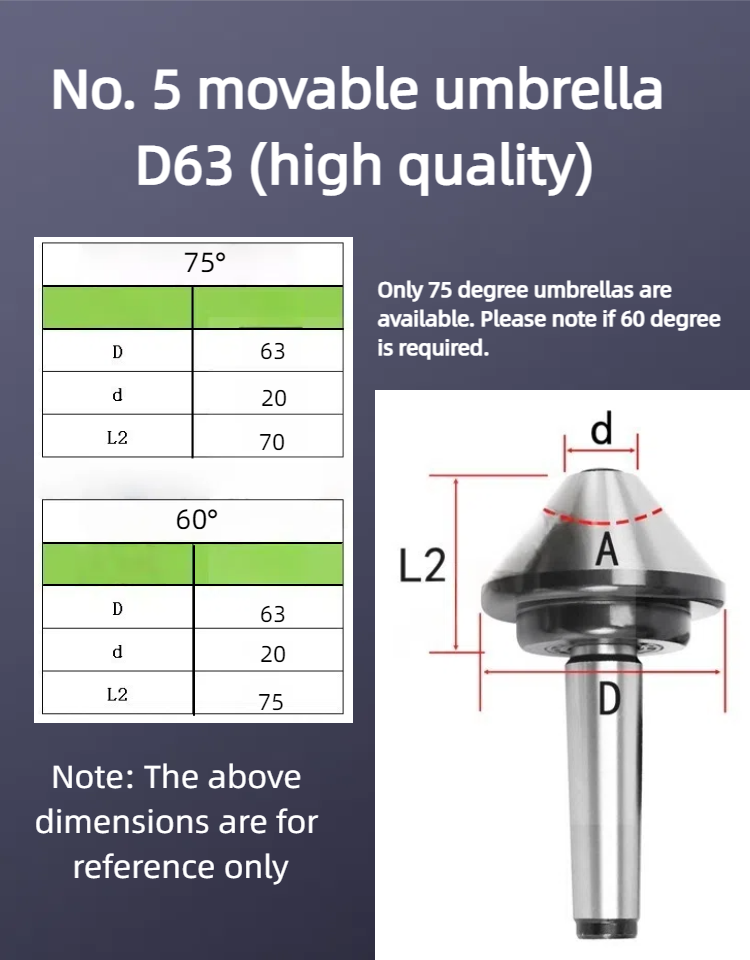

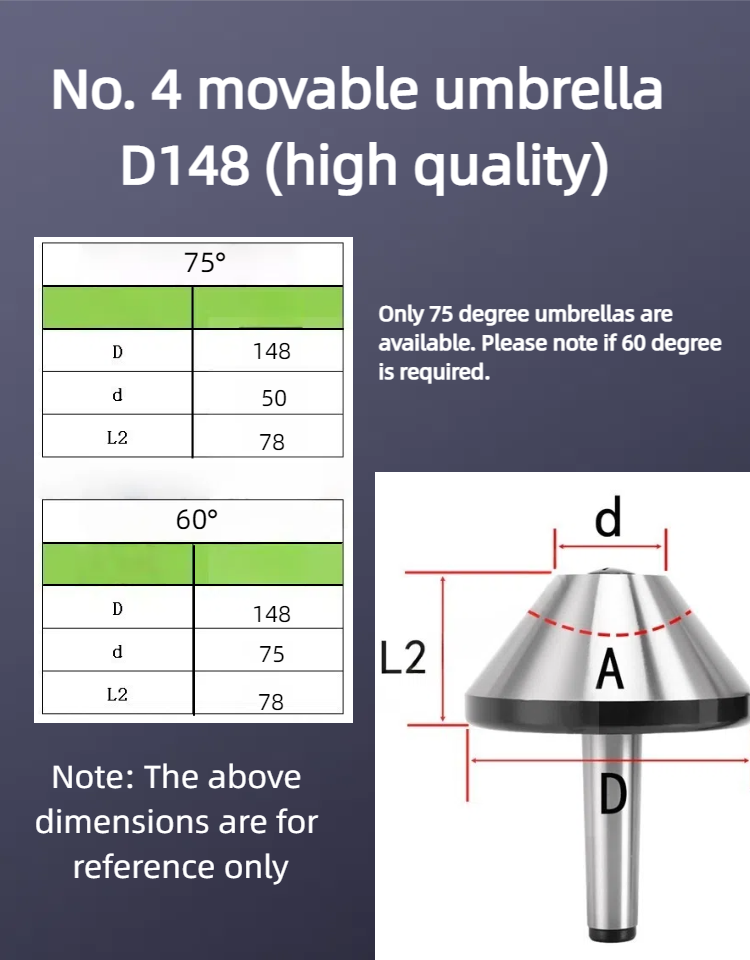

The cone angle of the umbrella-shaped revolving top is one of its important structural parameters. Generally speaking, its cone angle is commonly 60° or 75°, and a few are designed to be 90°. Different cone angle designs are suitable for different processing scenarios and workpiece types. For example, the umbrella-shaped revolving top with a 60° cone angle performs well in terms of versatility and can adapt to the processing of workpieces with inner hole sizes ranging from tens of millimeters to one or two hundred millimeters. This is because when the 60° cone angle contacts the inner hole of the workpiece, it can adapt to different apertures within a certain range and achieve stable support by adjusting the contact position. However, this large cone angle umbrella-shaped revolving top also has certain disadvantages, namely, the positioning accuracy is relatively low. The outer circle or end face processed by it has a relatively large position error. This is because when the large cone angle contacts the workpiece, the contact area is relatively small, and under the action of external forces such as cutting force, it is easy to produce a small displacement, which makes it difficult to achieve a high level of position accuracy of the processed workpiece.