BT40-SK High Precision CNC Tool Holder

Made of carbide material and combined with precision machining technology, the radial runout accuracy of the tool holder is ≤0.003mm, which is suitable for high-precision machining needs.Dynamic balance design (G2.5 level), supports a maximum speed of 12,000 RPM, effectively reduces vibration during high-speed cutting and extends tool life

Adapt to BT40 spindle interface, compatible with mainstream CNC machining center brands (such as Mitsubishi, Hitachi, Kyocera, etc.), and support ER collet, heat shrink handle and other clamping methods.

The special surface coating treatment enhances wear resistance and rust resistance, suitable for heavy cutting and continuous processing environments. Optional center water outlet function (some models) improves cooling efficiency, suitable for deep hole processing and high temperature material cutting.

Provides a full range of stock specifications, supports customized requirements (such as different nose lengths, lubrication methods), and meets diverse processing scenarios

BT40-SK CNC toolholder is a high-precision, high-rigidity machine tool designed for CNC machine tools. Made of high-quality alloy steel, it is precision machined and heat-treated to ensure its stability and durability in high-speed cutting. The unique conical surface design inside the toolholder can effectively improve the clamping force and concentricity of the tool, reduce vibration, and improve processing accuracy.BT40-SK CNC toolholders are widely used in automotive manufacturing, aerospace, mold processing, precision parts manufacturing and other fields. Whether it is the processing of aluminum alloy, stainless steel or titanium alloy and other materials, BT40-SK can provide excellent performance support.

Product Advantages:

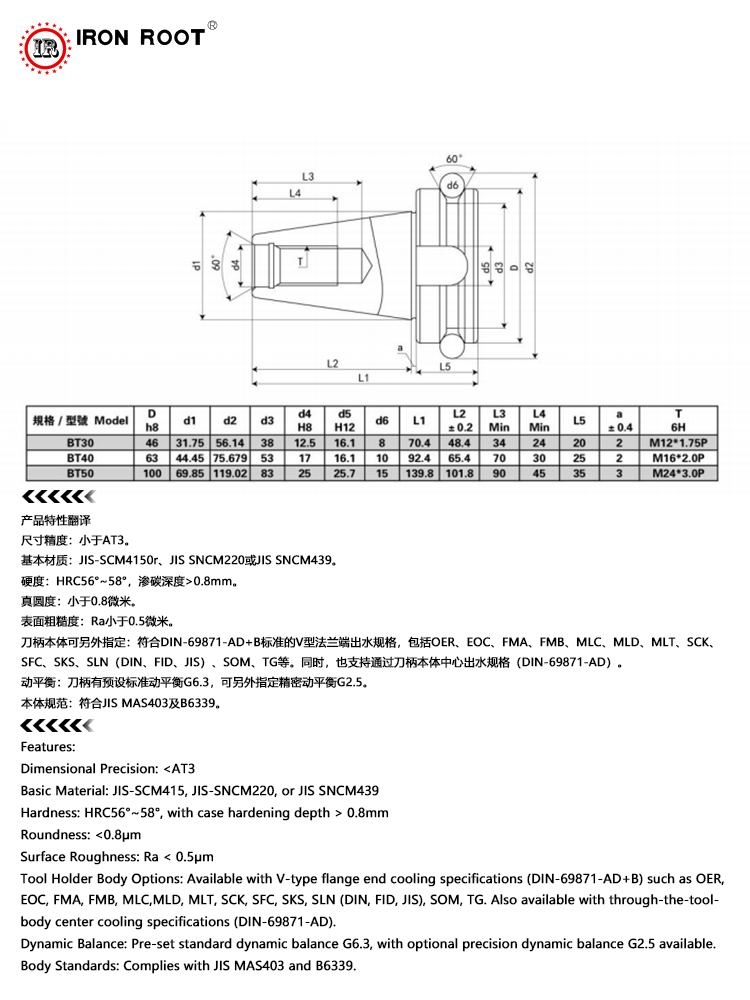

1.High Precision: The BT40-SK CNC Tool Holder meets the DIN69871 standard for taper accuracy, ensuring minimal runout after tool installation, making it ideal for high-precision machining.

2.High Rigidity: Its reinforced structure allows it to withstand greater cutting forces, suitable for heavy-duty and high-speed machining.

3.Wide Application: Perfect for milling, drilling, tapping, and other machining operations, it is an excellent choice for CNC machines.

4.Long Service Life: The special heat treatment process provides exceptional wear resistance and fatigue strength, extending its lifespan.

Application Range: