IRON ROOT 5D internal coolant drill, carbide coating, efficient chip removal, fixed shank design

1. Material and process advantages

High hardness and wear-resistant material

Using integral cemented carbide, the hardness at room temperature can reach HRC58, and it can still maintain stable performance at high temperature. The wear resistance is far superior to high-speed steel drill bits, which is suitable for processing high-hardness materials such as stainless steel and titanium alloy.

2. Structural design advantages

The hard fixed handle structure is suitable for CNC machine tool handles, with radial runout less than 0.0025mm, reducing drilling shaking, and the aperture error is controlled within ±0.005mm.

3. Processing performance advantages

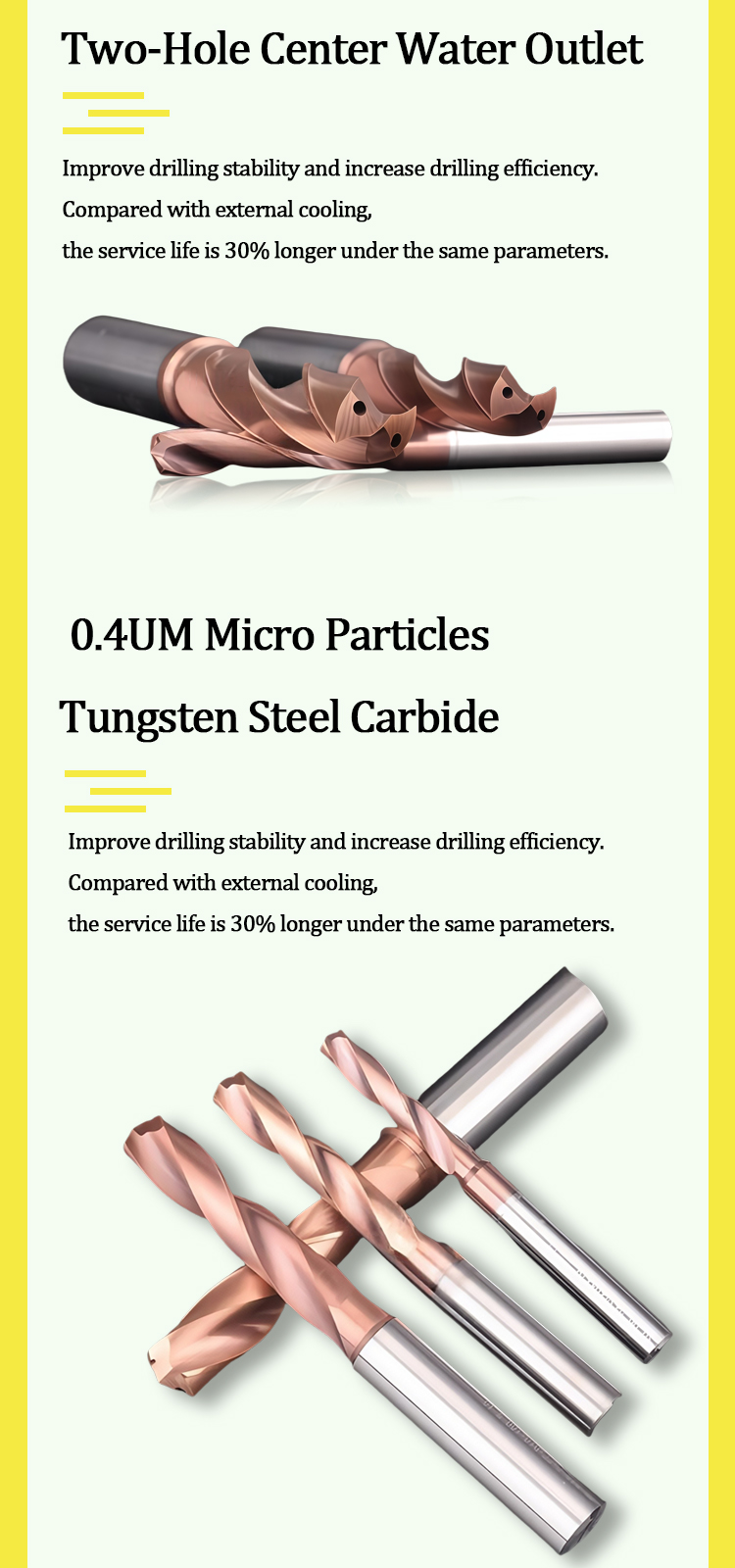

The spiral groove and internal coolant work together to increase chip removal efficiency by 50%, avoiding the risk of tool breakage caused by blockage, which is especially suitable for continuous processing environments.

4. Economic advantages

Adaptable to a variety of machine tool cooling systems (internal cooling/external cooling), supporting non-standard customization (such as special diameters, coating requirements), and meeting personalized production needs.

5. Application scenario advantages

Multi-material applicability

It can process difficult-to-cut materials such as stainless steel, high-temperature alloys, titanium alloys, and hardened steel, covering automobiles, molds, aerospace and other fields.

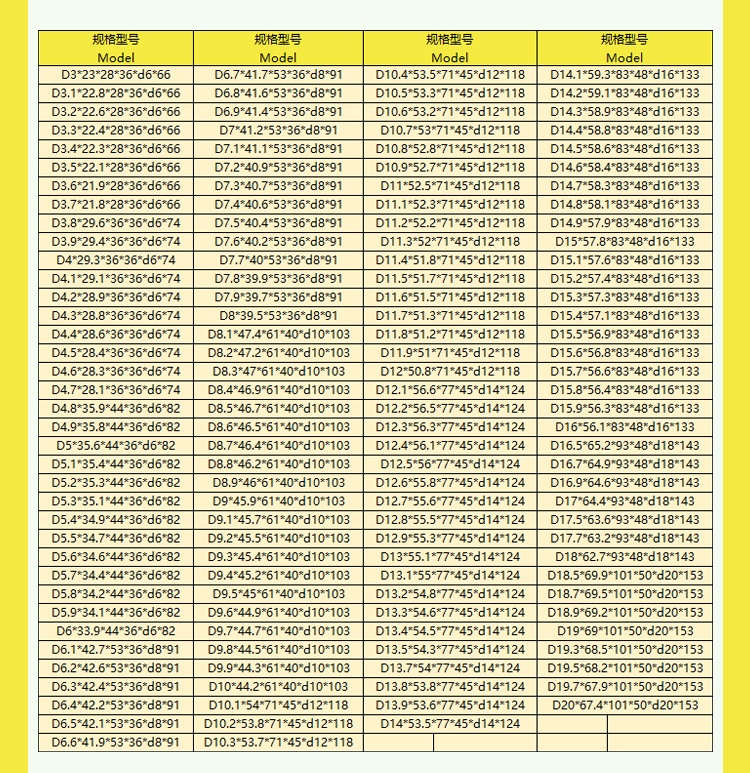

| 规格型号 Model | 规格型号 Model | 规格型号 Model | 规格型号 Model | ||||

| D3*23*28*36*d6*66 | D6.7*41.7*53*36*d8*91 | D10.4*53.5*71*45*d12*118 | D14.1*59.3*83*48*d16*133 | ||||

| D3.1*22.8*28*36*d6*66 | D6.8*41.6*53*36*d8*91 | D10.5*53.3*71*45*d12*118 | D14.2*59.1*83*48*d16*133 | ||||

| D3.2*22.6*28*36*d6*66 | D6.9*41.4*53*36*d8*91 | D10.6*53.2*71*45*d12*118 | D14.3*58.9*83*48*d16*133 | ||||

| D3.3*22.4*28*36*d6*66 | D7*41.2*53*36*d8*91 | D10.7*53*71*45*d12*118 | D14.4*58.8*83*48*d16*133 | ||||

| D3.4*22.3*28*36*d6*66 | D7.1*41.1*53*36*d8*91 | D10.8*52.8*71*45*d12*118 | D14.5*58.6*83*48*d16*133 | ||||

| D3.5*22.1*28*36*d6*66 | D7.2*40.9*53*36*d8*91 | D10.9*52.7*71*45*d12*118 | D14.6*58.4*83*48*d16*133 | ||||

| D3.6*21.9*28*36*d6*66 | D7.3*40.7*53*36*d8*91 | D11*52.5*71*45*d12*118 | D14.7*58.3*83*48*d16*133 | ||||

| D3.7*21.8*28*36*d6*66 | D7.4*40.6*53*36*d8*91 | D11.1*52.3*71*45*d12*118 | D14.8*58.1*83*48*d16*133 | ||||

| D3.8*29.6*36*36*d6*74 | D7.5*40.4*53*36*d8*91 | D11.2*52.2*71*45*d12*118 | D14.9*57.9*83*48*d16*133 | ||||

| D3.9*29.4*36*36*d6*74 | D7.6*40.2*53*36*d8*91 | D11.3*52*71*45*d12*118 | D15*57.8*83*48*d16*133 | ||||

| D4*29.3*36*36*d6*74 | D7.7*40*53*36*d8*91 | D11.4*51.8*71*45*d12*118 | D15.1*57.6*83*48*d16*133 | ||||

| D4.1*29.1*36*36*d6*74 | D7.8*39.9*53*36*d8*91 | D11.5*51.7*71*45*d12*118 | D15.2*57.4*83*48*d16*133 | ||||

| D4.2*28.9*36*36*d6*74 | D7.9*39.7*53*36*d8*91 | D11.6*51.5*71*45*d12*118 | D15.3*57.3*83*48*d16*133 | ||||

| D4.3*28.8*36*36*d6*74 | D8*39.5*53*36*d8*91 | D11.7*51.3*71*45*d12*118 | D15.4*57.1*83*48*d16*133 | ||||

| D4.4*28.6*36*36*d6*74 | D8.1*47.4*61*40*d10*103 | D11.8*51.2*71*45*d12*118 | D15.5*56.9*83*48*d16*133 | ||||

| D4.5*28.4*36*36*d6*74 | D8.2*47.2*61*40*d10*103 | D11.9*51*71*45*d12*118 | D15.6*56.8*83*48*d16*133 | ||||

| D4.6*28.3*36*36*d6*74 | D8.3*47*61*40*d10*103 | D12*50.8*71*45*d12*118 | D15.7*56.6*83*48*d16*133 | ||||

| D4.7*28.1*36*36*d6*74 | D8.4*46.9*61*40*d10*103 | D12.1*56.6*77*45*d14*124 | D15.8*56.4*83*48*d16*133 | ||||

| D4.8*35.9*44*36*d6*82 | D8.5*46.7*61*40*d10*103 | D12.2*56.5*77*45*d14*124 | D15.9*56.3*83*48*d16*133 | ||||

| D4.9*35.8*44*36*d6*82 | D8.6*46.5*61*40*d10*103 | D12.3*56.3*77*45*d14*124 | D16*56.1*83*48*d16*133 | ||||

| D5*35.6*44*36*d6*82 | D8.7*46.4*61*40*d10*103 | D12.4*56.1*77*45*d14*124 | D16.5*65.2*93*48*d18*143 | ||||

| D5.1*35.4*44*36*d6*82 | D8.8*46.2*61*40*d10*103 | D12.5*56*77*45*d14*124 | D16.7*64.9*93*48*d18*143 | ||||

| D5.2*35.3*44*36*d6*82 | D8.9*46*61*40*d10*103 | D12.6*55.8*77*45*d14*124 | D16.9*64.6*93*48*d18*143 | ||||

| D5.3*35.1*44*36*d6*82 | D9*45.9*61*40*d10*103 | D12.7*55.6*77*45*d14*124 | D17*64.4*93*48*d18*143 | ||||

| D5.4*34.9*44*36*d6*82 | D9.1*45.7*61*40*d10*103 | D12.8*55.5*77*45*d14*124 | D17.5*63.6*93*48*d18*143 | ||||

| D5.5*34.7*44*36*d6*82 | D9.2*45.5*61*40*d10*103 | D12.9*55.3*77*45*d14*124 | D17.7*63.2*93*48*d18*143 | ||||

| D5.6*34.6*44*36*d6*82 | D9.3*45.4*61*40*d10*103 | D13*55.1*77*45*d14*124 | D18*62.7*93*48*d18*143 | ||||

| D5.7*34.4*44*36*d6*82 | D9.4*45.2*61*40*d10*103 | D13.1*55*77*45*d14*124 | D18.5*69.9*101*50*d20*153 | ||||

| D5.8*34.2*44*36*d6*82 | D9.5*45*61*40*d10*103 | D13.2*54.8*77*45*d14*124 | D18.7*69.5*101*50*d20*153 | ||||

| D5.9*34.1*44*36*d6*82 | D9.6*44.9*61*40*d10*103 | D13.3*54.6*77*45*d14*124 | D18.9*69.2*101*50*d20*153 | ||||

| D6*33.9*44*36*d6*82 | D9.7*44.7*61*40*d10*103 | D13.4*54.5*77*45*d14*124 | D19*69*101*50*d20*153 | ||||

| D6.1*42.7*53*36*d8*91 | D9.8*44.5*61*40*d10*103 | D13.5*54.3*77*45*d14*124 | D19.3*68.5*101*50*d20*153 | ||||

| D6.2*42.6*53*36*d8*91 | D9.9*44.3*61*40*d10*103 | D13.7*54*77*45*d14*124 | D19.5*68.2*101*50*d20*153 | ||||

| D6.3*42.4*53*36*d8*91 | D10*44.2*61*40*d10*103 | D13.8*53.8*77*45*d14*124 | D19.7*67.9*101*50*d20*153 | ||||

| D6.4*42.2*53*36*d8*91 | D10.1*54*71*45*d12*118 | D13.9*53.6*77*45*d14*124 | D20*67.4*101*50*d20*153 | ||||

| D6.5*42.1*53*36*d8*91 | D10.2*53.8*71*45*d12*118 | D14*53.5*77*45*d14*124 | |||||

| D6.6*41.9*53*36*d8*91 | D10.3*53.7*71*45*d12*118 | ||||||

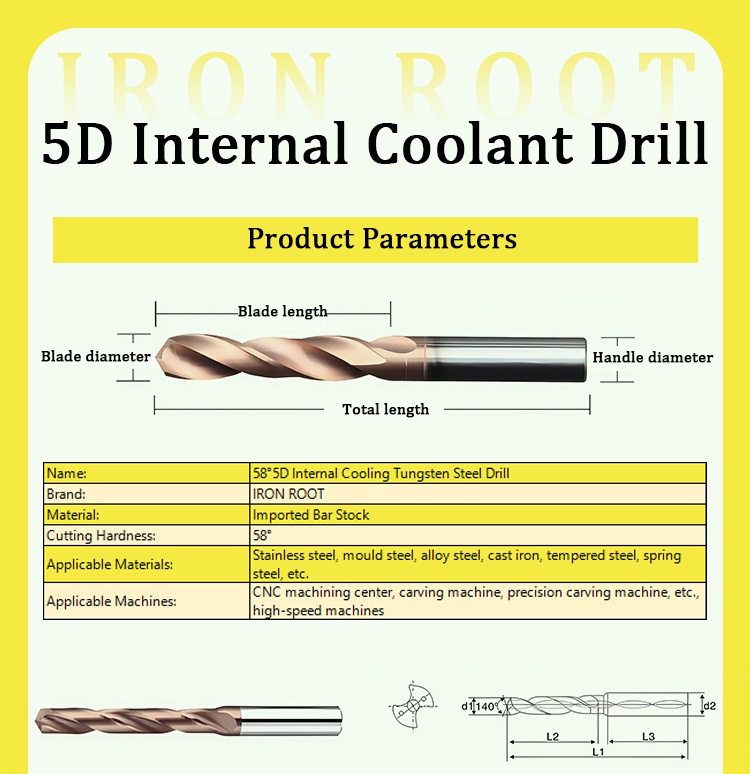

| Name: | 58°5D Internal Cooling Tungsten Steel Drill |

| Brand: | IRON ROOT |

| Material: | Imported Bar Stock |

| Cutting Hardness: | 58° |

| Applicable Materials: | Stainless steel, mould steel, alloy steel, cast iron, tempered steel, spring steel, etc. |

| Applicable Machines: | CNC machining center, carving machine, precision carving machine, etc., high-speed machines |

Ordering Information:

For accurate pricing and delivery details for our APMT Milling Inserts, please reach out to our sales team. We also provide tailored solutions to fit your unique project needs. Let us help you find the perfect match for your requirements.