ironroot SPGT Inserts: A Hit with Machinists

When Mike Patel, owner of Precision Turners Workshop, first unboxed the carbide insert U-drills, he admits he didn’t expect much. “Just another set of bits, I thought,” he laughs. Three months later, he’s singing a different tune.

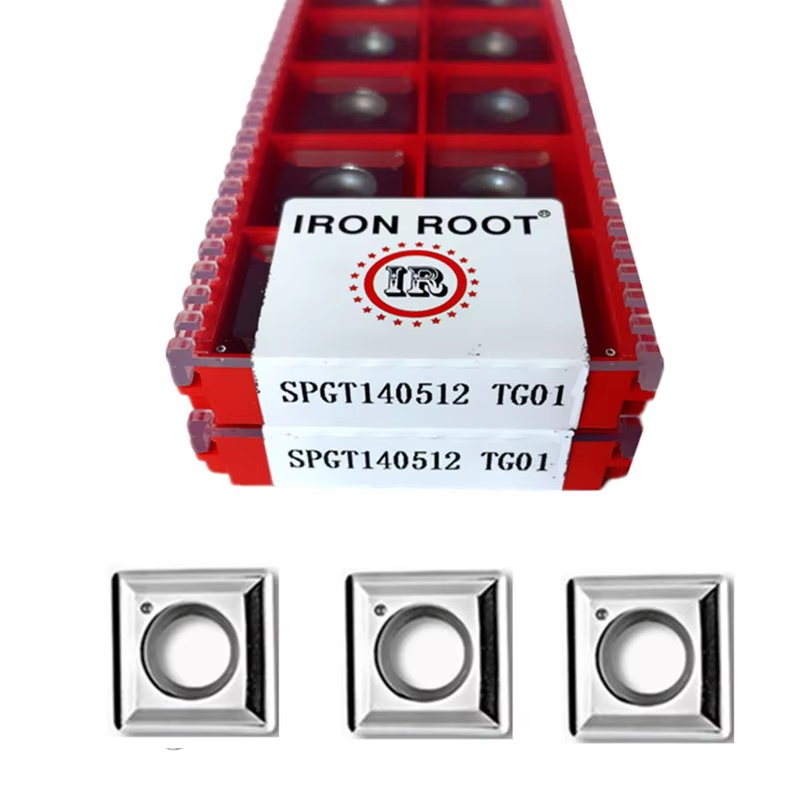

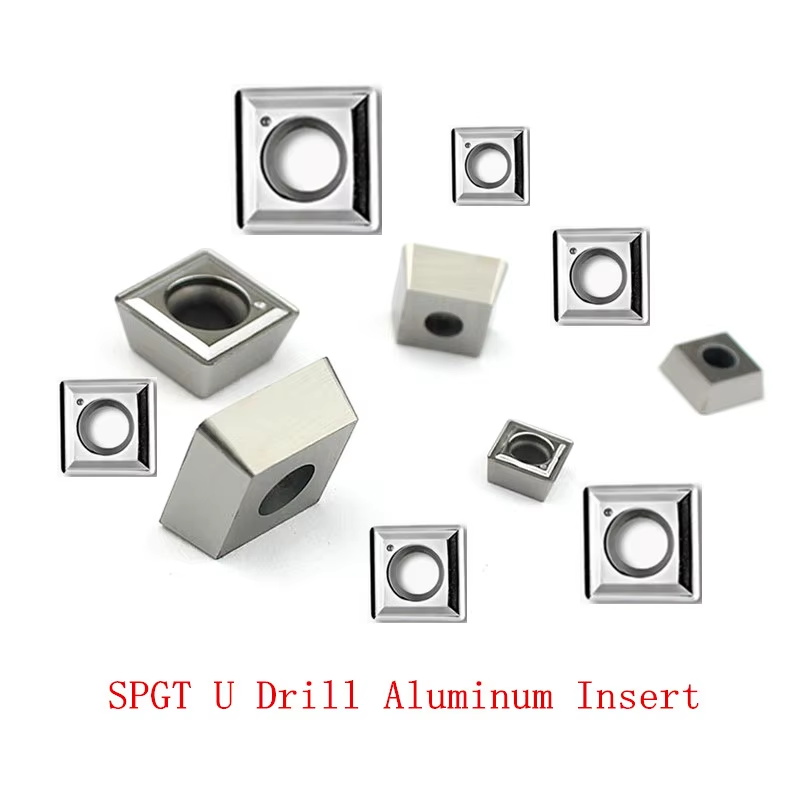

These inserts—including the ironroot SPGT050204, SPGT060204, SPGT090408, and SPGT110408—are built with high-grade carbide, a material known for its toughness against hard metals like stainless steel and cast iron. Designed for CNC metal lathe tools (especially TG01 models), they’re made to handle everything from small, precise holes to deep, large-diameter drilling.

“Take the ironroot SPGT090408—we use it for drilling stainless steel hubs, and it’s a beast,” Patel says, holding up the small but sturdy insert. “Before, we’d burn through a drill every 50 parts. This one? We’re at 300 and counting, and it still cuts like it’s brand new. The guys in the shop call it ‘the little workhorse.’”

Over at Metro Machining, foreman Lisa Chen is equally impressed, especially with the indexable design—a key feature that lets users swap inserts in seconds instead of wrestling with whole tools. “We used to spend 15 minutes fumbling with tool changes—now, swapping out an ironroot SPGT060204 takes 30 seconds,” she explains, demonstrating a quick insert swap on their TG01 CNC lathe. “Our morning shift alone has cranked out 20% more parts since we switched. The team’s even stopped groaning when we get a big order.”

For small shops like Raj’s Metal Works, the cost savings have been a game-changer. “The ironroot SPGT110408 handles our deep-hole jobs in cast iron without breaking a sweat,” Raj says, showing off a batch of perfectly drilled brackets. “I used to budget for new drills every week. Now? I’m putting that money back into the business. Who knew a tiny carbide insert could make such a difference?”

From busy factories tackling high-volume runs to family-run workshops crafting custom parts, these inserts prove that big results can come in small packages. As Patel puts it: “When your equipment works this hard, you can’t help but work smarter, not harder.”