What are CBN inserts used for

ironroot CBN inserts—short for Cubic Boron Nitride inserts—are the heavyweights of precision machining, built to tackle the toughest materials that would wear down standard carbide or HSS (high-speed steel) tools. Think of them as the "diamond of the metalworking world" (though CBN is second only to diamond in hardness) — designed for jobs where heat, hardness, and precision non-negotiable.

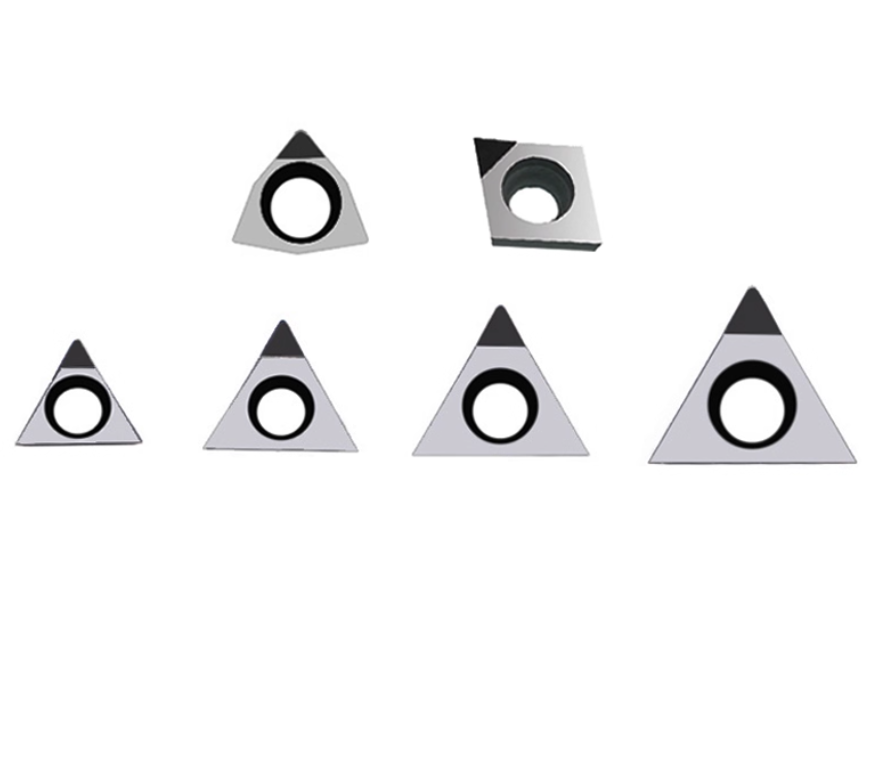

![CBN inserts CBN inserts]()

The #1 job for ironroot CBN insert is cutting

hardened steel (50–65 HRC), a material that turns

carbide inserts into scrap in minutes. This includes:

Automotive components: Brake rotors, transmission gears, and axle shafts (often heat-treated to 55–60 HRC for durability).

Tooling & dies: Mold cores, stamping dies, and drill bits (hardened to 60–65 HRC to resist wear).

Aerospace parts: Landing gear components or engine shafts (hardened steel for strength under extreme stress).

User quote: “We used to grind hardened gear blanks—it took 45 minutes per part,” says Carlos Mendez, a CNC supervisor at an automotive parts plant. “Now with CBN inserts, we ‘turn and burn’ them in 8 minutes flat. The finish is so smooth (Ra 0.8μm) we don’t need post-grinding anymore. My team went from dreading gear runs to knocking out 20+ parts a shift.”

CBN thrives in

high-temperature, high-speed cutting—perfect for gray

cast iron (GG25/GG30) or ductile cast iron (GJS400), common in:

![CBN inserts CBN inserts]()

User quote: “Cast iron used to clog our carbide inserts with chips and wear edges in 30 minutes,” explains Priya Sharma, a manufacturing engineer at a pump manufacturer. “CBN inserts? They run at 300+ m/min (1,000+ SFM) and stay sharp for 4 hours. We cut cycle time by 60% and haven’t had a tool failure in months.”

For "impossible" materials like titanium alloys (Ti-6Al-4V), Inconel (nickel-based superalloys), or Hastelloy (corrosion-resistant alloys), CBN inserts are a lifeline. These materials are used in:

Aerospace: CBN inserts for hard turning Turbine blades, jet engine casings (superalloys handle 1,000°C+ temperatures).

Energy: Gas turbine components or nuclear reactor parts (need corrosion resistance and precision).

![CBN inserts CBN inserts]()

User quote: “Inconel was a nightmare with carbide—we’d get ‘built-up edge’ (BUE) that ruined parts,” says Rajiv Kumar, an aerospace machinist. “CBN inserts cut through it like butter, even at 150 m/min. The tolerances are spot-on (+/- 0.01mm), and we’re finally meeting our delivery deadlines.”

CBN’s ultra-hard surface (9.5 on the Mohs scale) delivers mirror-like surface finishes (Ra 0.2–1.6μm) on hard materials—eliminating the need for grinding, lapping, or polishing. This is critical for:

![CBN inserts CBN inserts]()

User quote: “We make

stainless steel surgical drills that need a Ra 0.4μm finish,” says Lisa Chen, a medical device manufacturer. “Before CBN, we turned with carbide then ground—2 steps, 2 hours. Now CBN does it in 45 minutes, and the finish is better. Our QA team loves it.”

CBN outperforms carbide in hard, high-heat applications because:

It’s 3x more heat-resistant (handles 1,300°C vs. carbide’s 800°C).

It’s harder (9.5 vs. carbide’s 8.5 on the Mohs scale), so it resists wear on abrasive materials.

It doesn’t react with iron (unlike diamond, which oxidizes in steel), making it safe for steel/iron machining.

![CBN inserts CBN inserts]()

Automotive manufacturers: cnc cutting tools For hardened gears, brake parts, and engine components.

Aerospace & defense: For superalloy turbine parts and landing gear.

Medical device makers: For precision hardened steel or titanium implants.

Heavy machinery shops:cbn inserts price For cast iron housings and large steel shafts.

![CBN inserts CBN inserts]()

Thank you very much for watching

Welcome to inquire about the prices, and we will provide you with the best service.

Website: https://www.ironrootcnctools.com

Whatsapp/Mobile: +86 13969129141

Email: lronroot190@gmail.com

![ironroot customer service ironroot customer service]()