What is a SNMG insert?

What is a SNMG insert?

If CNC turning had a MVP, the new SNMG carbide insert from a leading machining solutions brand might just take the trophy. This square-shaped powerhouse isn’t here for fancy tricks—it’s built to tackle the toughest cuts, crank out consistent results, and keep production lines rolling. Think of it as the “workhorse” of your lathe: reliable, tough, and ready to handle whatever steel, stainless steel, or cast iron you throw at it.

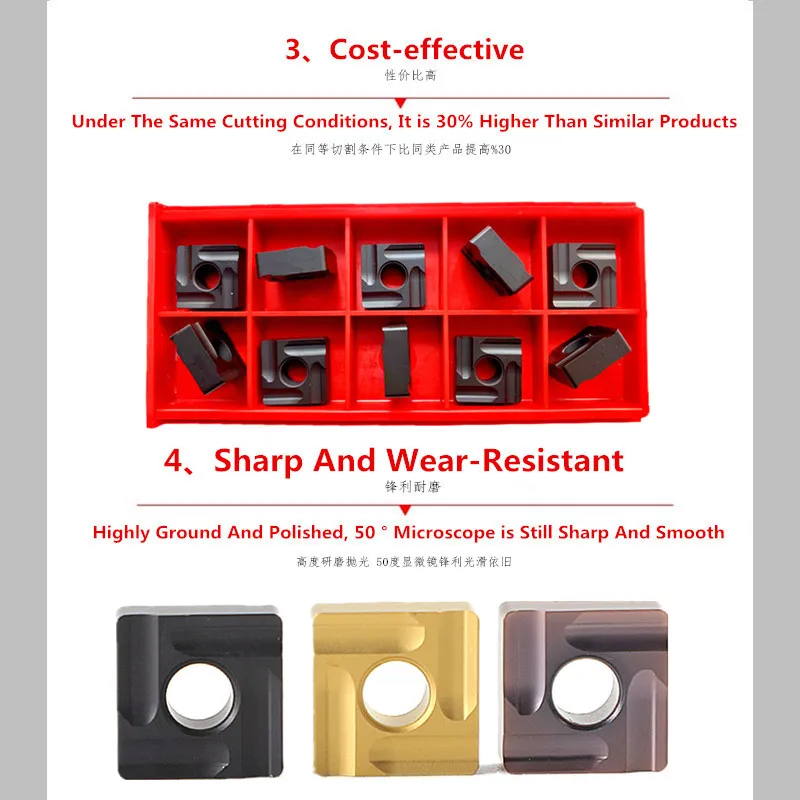

Why SNMG Stands Out: Square Geometry = Unbeatable Strength

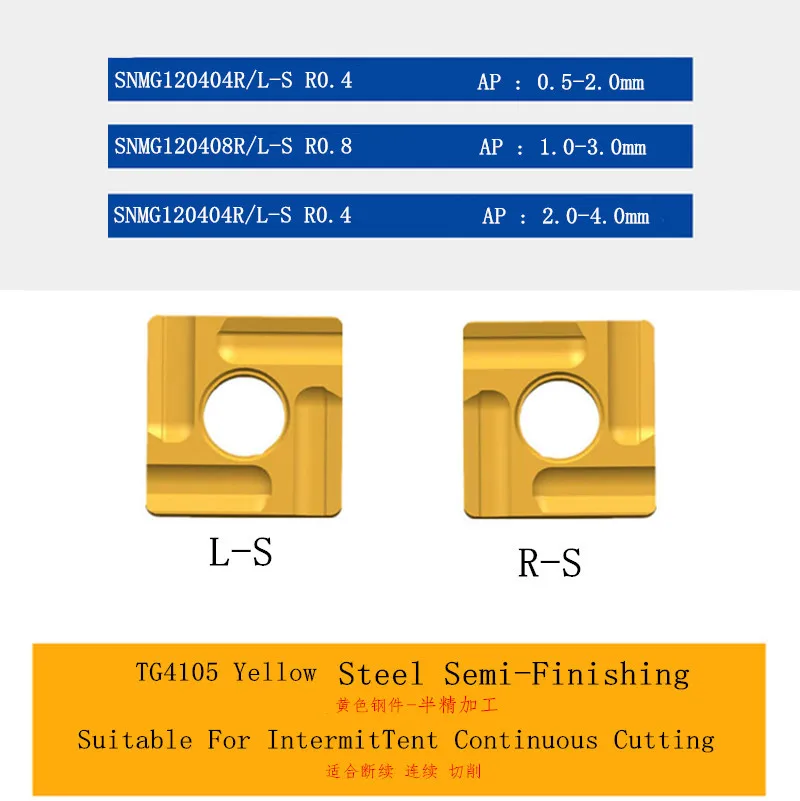

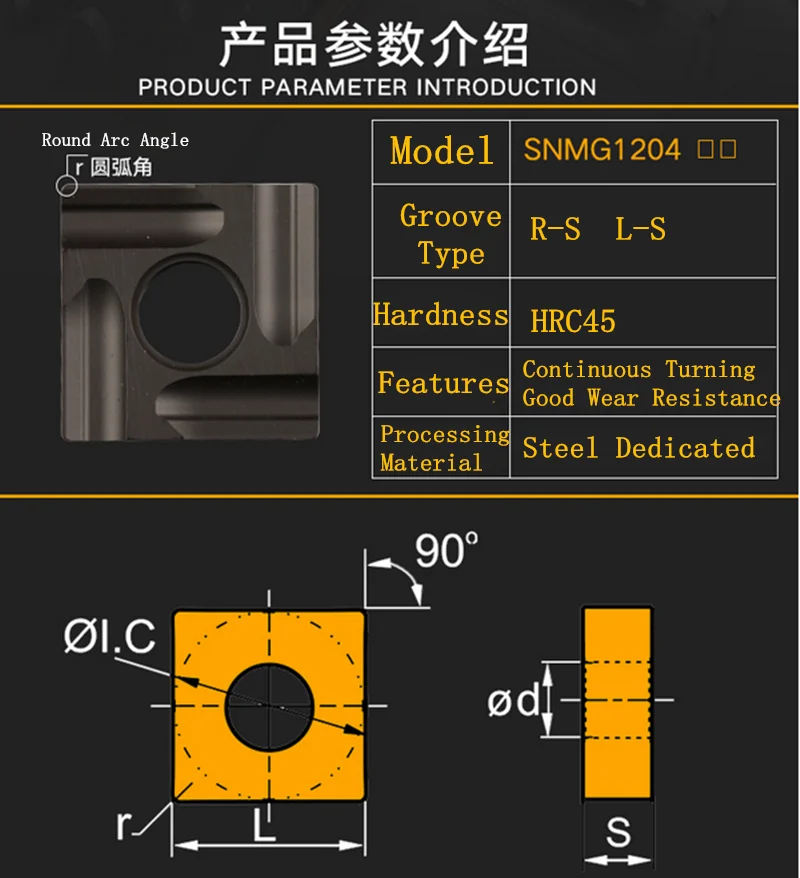

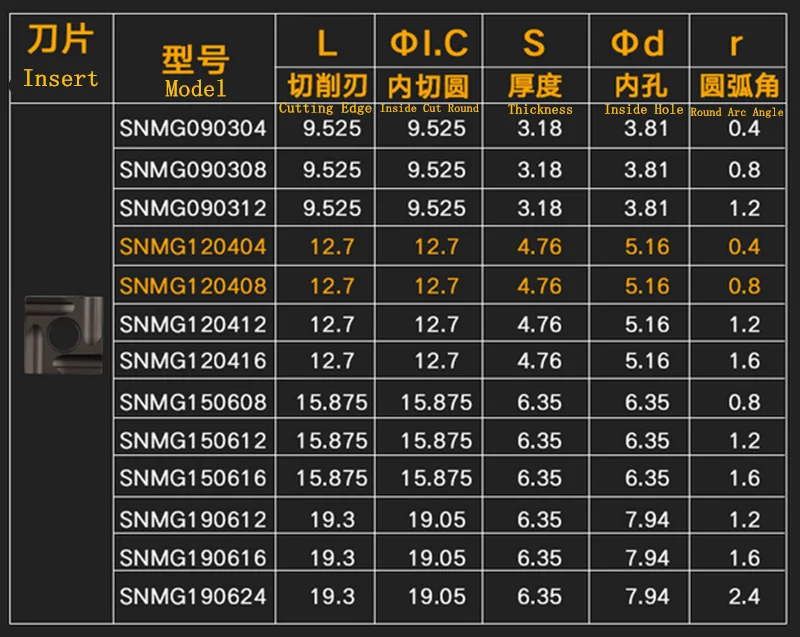

Unlike its diamond-shaped DNMG cousin, the SNMG insert rocks a 90° square design —and that’s no accident. The square shape gives it longer, sturdier cutting edges (up to 4 usable edges for indexability) that thrive in roughing, semi-finishing, and even heavy-duty turning. Its ISO 1832-standardized code (e.g., SNMG120412) spells out the details: 12mm cutting edge length, 4.76mm thickness, and a 1.2mm nose radius—all optimized for stability when machining thick stock or hard materials.

“It’s the square shape that sold me,” says Jake Torres, a cnc cutting tools at a industrial equipment factory. “When we’re roughing 2-inch steel bars, weaker inserts chip or wear out in 30 minutes. The SNMG? It plows through that steel like it’s nothing—we get 2+ hours of cutting before indexing. No more stopping mid-batch to swap tools.”

Material Mastery: One Insert, Multiple Jobs

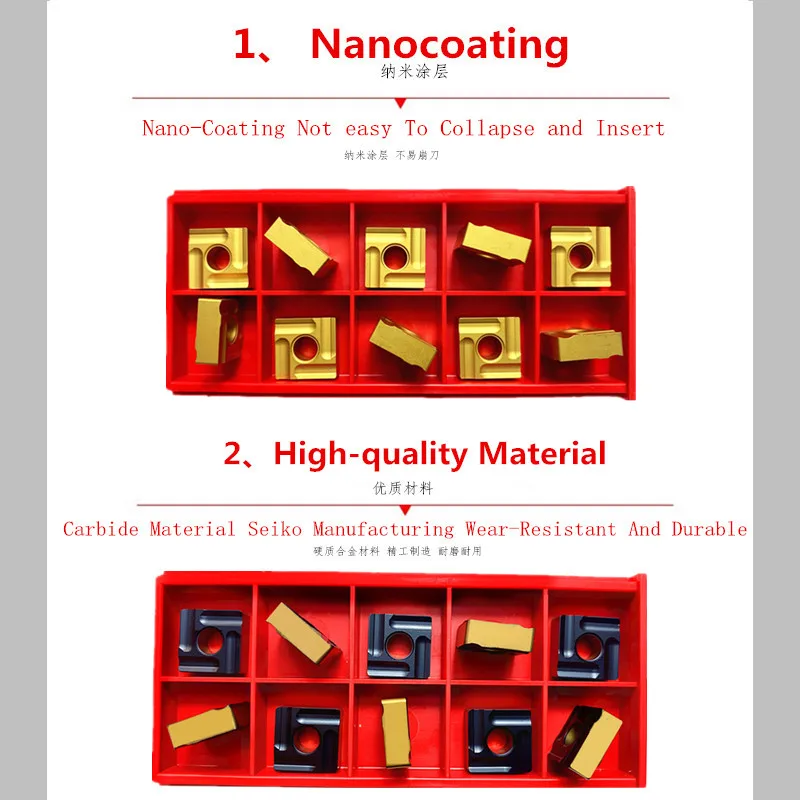

What makes SNMG a shop favorite is its chameleon-like ability to handle diverse materials, CNC Lathe Tool thanks to tailored carbide grades: - Steel Machining: Grades like LF9218 offer extreme wear resistance, standing up to high temperatures when turning carbon or alloy steel. - Stainless Steel: LF6018-grade SNMG inserts fight work hardening and built-up edge (BUE), keeping cuts clean on 304 or 316 stainless. - Cast Iron: Dedicated grades (e.g., K313) resist abrasion, making them ideal for machining gray or ductile iron components.

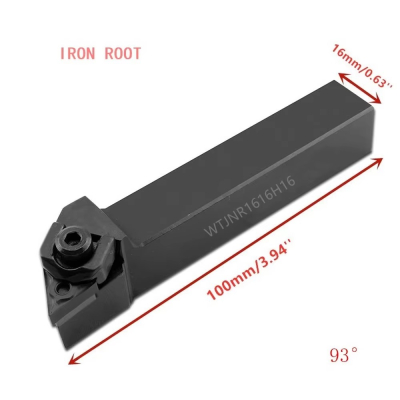

Plus, it fits standard tool holders (SCLCR, PCLNR, MTGNR) like a glove—no special adapters needed. “We used to keep 3 different insert types for steel, stainless, and iron,” says Maria Gonzalez, owner of a mid-sized machining shop. “Now we stock SNMG with different grades, and it covers 80% of our jobs. Less inventory, less confusion—total win.”

Indexable Magic: Save Time, Slash Costs

Like all indexable inserts, cnc tools SNMG’s superpower is its replaceable edges. When one edge wears down, just rotate it to a fresh one—no regrinding, no downtime. For high-volume shops, that’s a game-changer.

“Before SNMG, ironroot cnc tools we spent $500 a month on disposable inserts for our steel shaft production,” explains Ryan Hughes, a production manager at an automotive parts plant. “Now? We index the SNMG 4 times before replacing it, cutting tool costs by 40%. And since tool changes are down 60%, we’re cranking out 15% more parts a day. My boss is already asking about switching all our roughing jobs to SNMG.”

For Every Shop, Big or Small

Whether you’re a one-person operation machining custom iron brackets or a factory churning out thousands of steel gears, SNMG fits the bill. Its thick, rigid design handles heavy cuts, while smaller sizes (like SNMG090308) work for precision semi-finishing.

“I run a tiny shop out of my garage, snmg insert meaning and even I swear by ironroot SNMG,” says hobbyist-turned-pro Dave Kim. “I use it to turn steel motorcycle parts, and the consistency is insane—my customers can’t believe the finish I get with a ‘basic’ insert. And since it’s so durable, I don’t have to buy inserts every other week.”

Pick the Right SNMG in 3 Clicks

Choosing the perfect SNMG is easy: 1. Material: Match the grade (LF9218 for steel, LF6018 for stainless). 2. Cut Type: Go for a larger nose radius (1.2mm) for roughing, smaller (0.8mm) for finishing. 3. Holder: Check your tool holder’s specs for compatible insert size (e.g., 1204 = 12mm edge length).

The SNMG insert isn’t flashy—but it gets the job done, and then some. crabide inserts It’s the kind of tool that makes machinists smile, managers nod, and production lines hum. Ready to upgrade your lathe’s workhorse? Head to the manufacturer’s site or chat with their tech team—your next big job will thank you.

Thank you very much for watching

Welcome to inquire about the prices, and we will provide you with the best service.

Website: https://www.ironrootcnctools.

Whatsapp/Mobile: +86 13969129141

Email: lronroot190@gmail.com