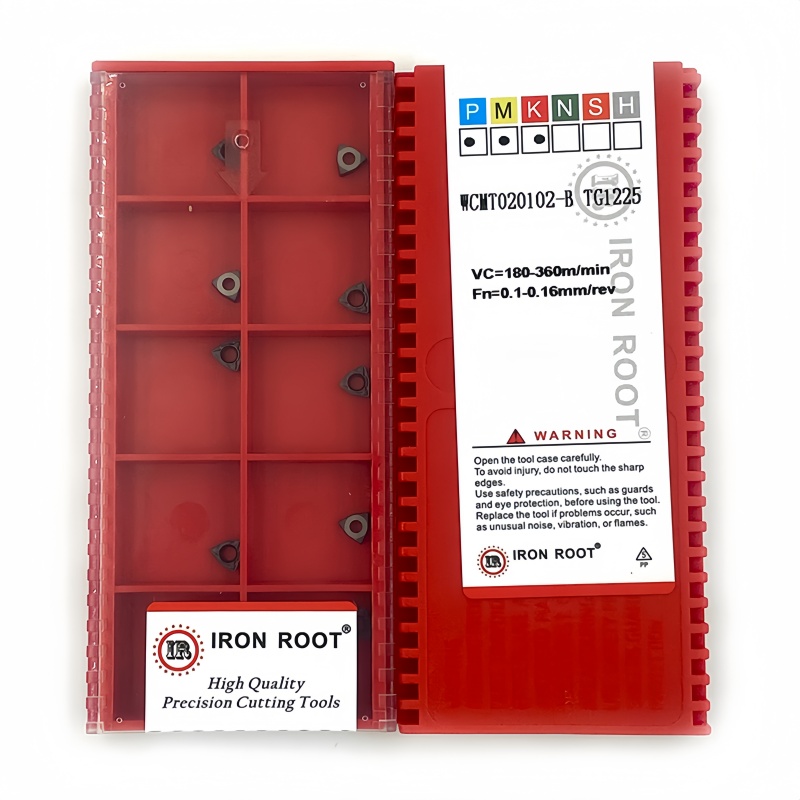

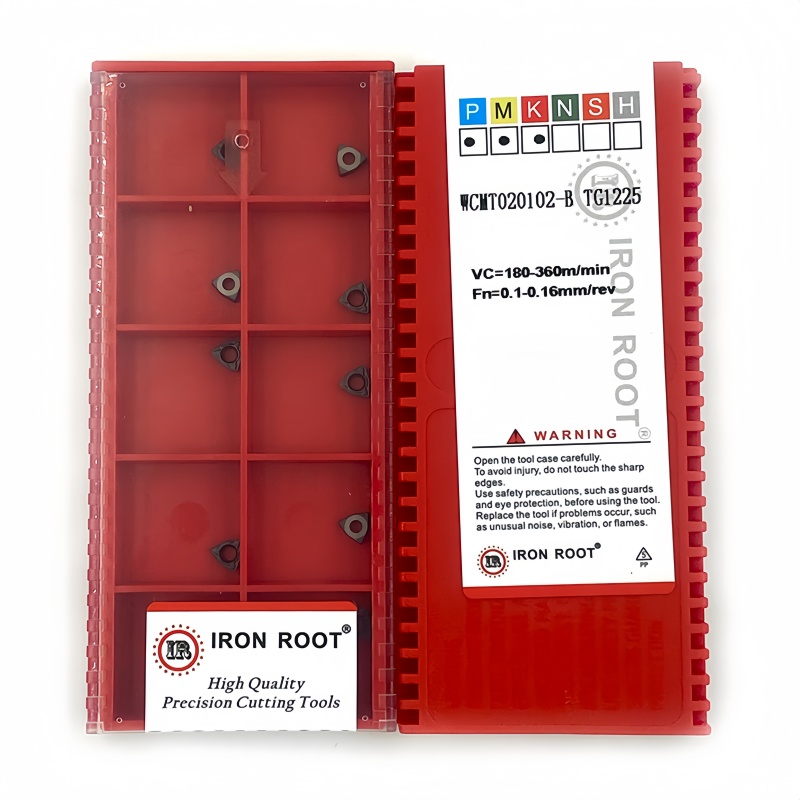

WCMT 020102-B High-Performance Shallow Drill Inserts

Excellent material: usually made of carbide, with high hardness and high wear resistance, it can withstand high cutting speeds and pressures, ensuring the stability and durability of the blade during processing.

Excellent cutting performance: The cutting edge of the blade is reasonably designed, sharp and precise, which can achieve high-precision turning, effectively reduce processing errors, and ensure the dimensional accuracy of the workpiece.

Wide range of processing: It is suitable for the processing of a variety of materials, including steel, stainless steel, cast iron, non-ferrous metals, etc., and can meet the cutting needs under different working conditions.

Long service life: Due to its high hardness and wear resistance, the WCMT020102-B blade wears less during processing, which can extend its service life and reduce the frequency of replacement.

Good process stability: The geometric shape and coating design of the blade help to improve the stability of the processing process, reduce the risk of vibration and tool breakage, and ensure the smooth progress of the processing process.

Easy installation: The blade is reasonably designed, and it is simple and quick to install on the turning tool bar, and can be quickly put into processing.

Adapt to a variety of cutting conditions: It has a wide process window, can adapt to different cutting parameters and processing conditions, and has strong flexibility

Excellent material: Made of high-quality cemented carbide, it has high hardness and high wear resistance, ensuring stability and durability during processing.

Excellent cutting performance: The cutting edge is reasonably designed and sharp, which can achieve high-precision turning, reduce processing errors, and ensure the dimensional accuracy of the workpiece.

Long service life: High hardness and wear resistance make it less worn during processing, extend service life, and reduce replacement frequency.

Good process stability: The geometric shape and coating design help to improve processing stability, reduce vibration and tool breakage risks, and ensure smooth processing.

Easy installation: Reasonable design, simple and quick installation on the turning tool bar, can be quickly put into processing.

Adapt to a variety of cutting conditions: It has a wide process window, can adapt to different cutting parameters and processing conditions, and has strong flexibility.

Attribute characteristics

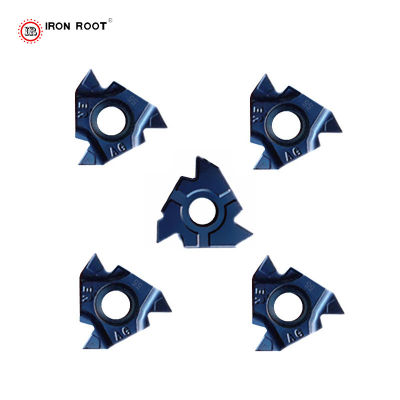

Shape and size: The WCMT020102-B blade has a specific shape and size, suitable for specific turning processing needs, such as shallow hole processing, etc.

Coating technology: Advanced PVD or CVD coating technology is usually used, such as TiN, Al₂O₃ and other coatings to improve wear resistance and high temperature resistance.

Edge design: The edge is precisely ground to keep it sharp, reduce cutting force and heat generation, and improve processing efficiency and surface quality.

Chipbreaker design: Equipped with an effective chipbreaker, it can effectively control the formation and discharge of chips and reduce the problem of chip entanglement and accumulation.

| brand | IRON ROOT |

| color | Gray black |

| Processing materials | Steel parts, stainless steel |

| coating | PVD |

| ISO | P15-P30、M10-M25 |

Features

High hardness and wear resistance: The carbide substrate is combined with advanced coatings to make it have excellent wear resistance while having high hardness, and is suitable for the processing of a variety of materials.

Good thermal stability: It can maintain stable performance at high temperatures, is not easily deformed or damaged, and adapts to the requirements of high-speed cutting.

Excellent impact resistance: Reasonable geometry and material selection enable it to remain intact when subjected to large cutting forces and impacts, reducing the risk of tool breakage.

Versatility: It is not only suitable for turning, but can also be used for drilling, boring and other operations under certain circumstances, and has a certain degree of versatility.

Application range

Material processing: Suitable for processing steel, stainless steel, cast iron, non-ferrous metals and other materials to meet the needs of different industrial fields.

Processing type: Widely used in shallow hole drilling, turning, boring, chamfering and other processing types, suitable for processing tasks with different precision and surface quality requirements.

Industrial field: It plays an important role in many industrial fields such as automobile manufacturing, mechanical processing, aerospace, mold manufacturing, electronic equipment, etc., providing reliable guarantee for high-precision and high-efficiency processing.