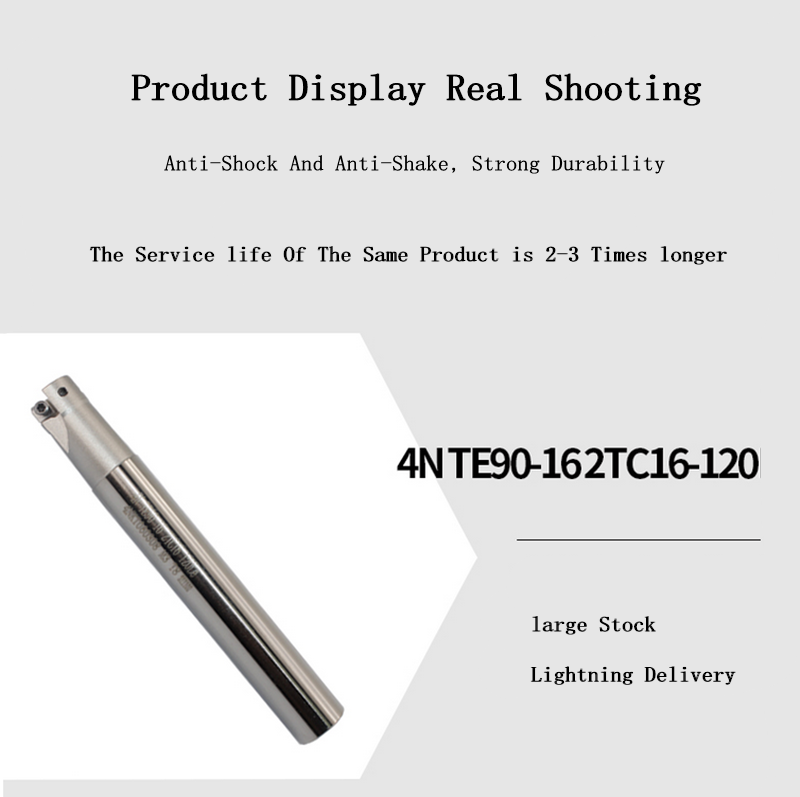

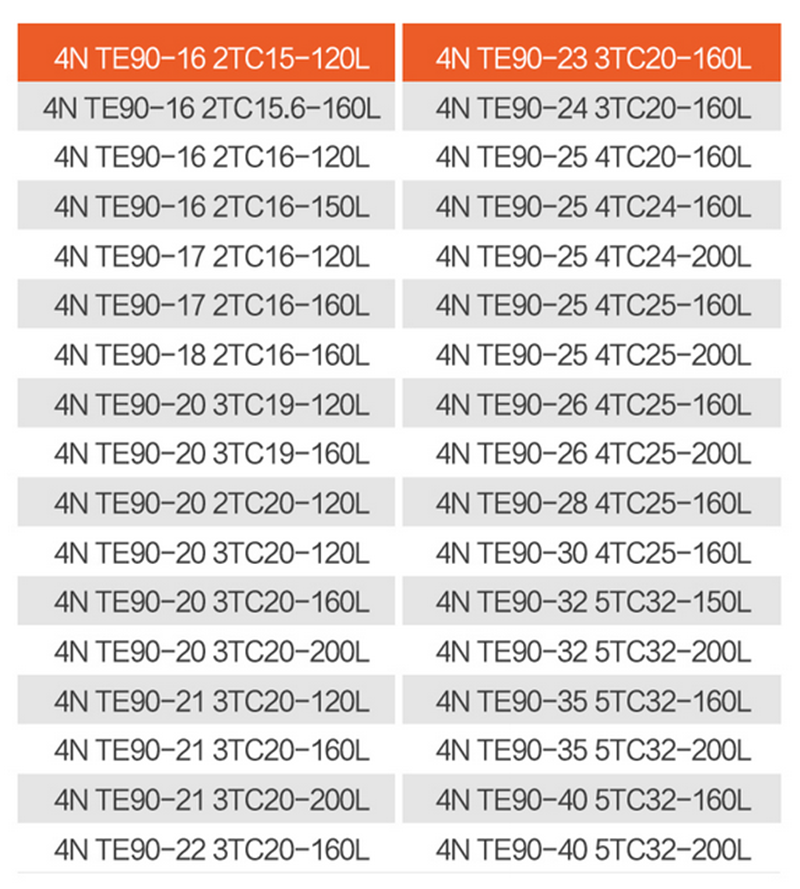

4NTE90 C32 C16 C19 C20 C24 C25 Double-sided milling cutter bar, machining center 4NKT blade CNC milling cutter TE90 series tool holder

Excellent processing performance

1. High ramping capability: It can achieve true 90-degree shoulder milling and has strong large-angle ramping capability, which can efficiently process complex contours and steep angles. It is suitable for processing occasions such as three-dimensional profiling milling, shoulder milling, slot milling, ramping milling, spiral interpolation milling, etc., and performs well in mold manufacturing, aerospace and other fields with high requirements for part contour accuracy.

2. Good cutting effect: The positive spiral blade makes cutting smoother and can obtain better surface finish, which helps to improve processing quality and reduce subsequent finishing processes such as grinding.

Low cost of use

1. Strong adaptability: Brand blades such as Tiger can be installed. Users can choose blades of different brands according to actual needs and costs, which improves the flexibility and economy of the tool system.

Long tool life

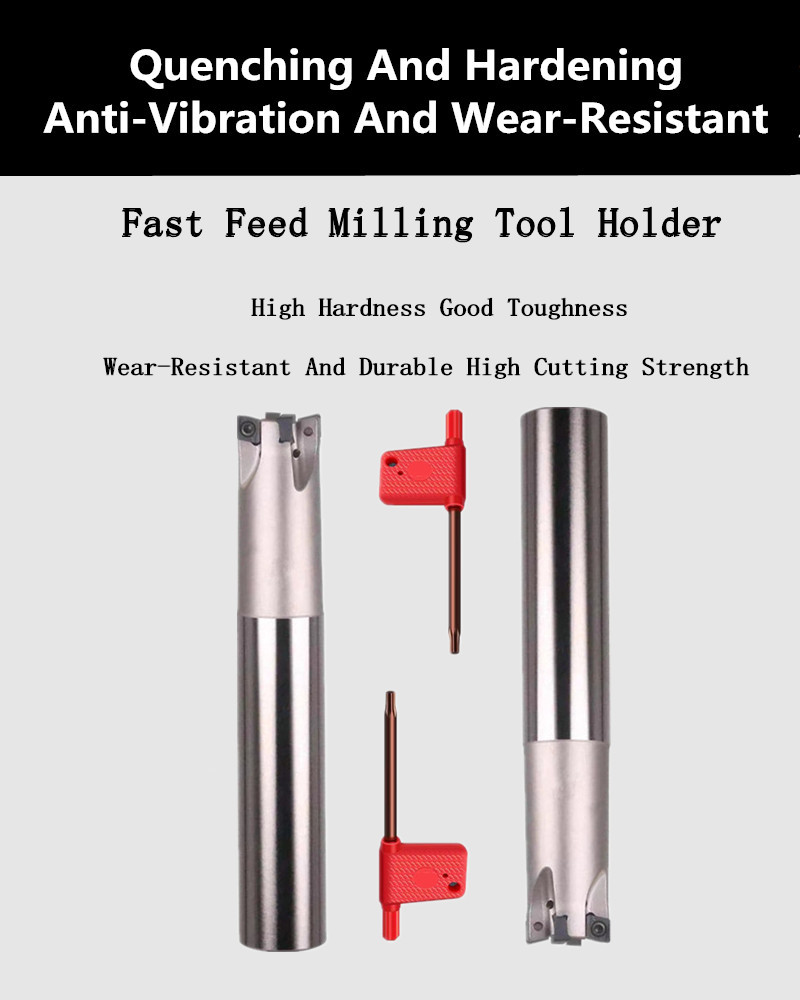

1. High-quality materials: Usually made of high-quality materials such as chromium-molybdenum alloy steel. After quenching and hardening, it has high hardness, high strength, good wear resistance, can withstand large cutting forces, is not easy to wear and deform, and extends the service life of the tool.

2. Advanced technology: Advanced manufacturing processes such as vacuum quenching are used to improve tool accuracy and performance stability. The precise matching design makes the blade fit closely with the tool position, which is not easy to break, reduces vibration, improves efficiency, and also helps to extend the service life of the tool.

High processing efficiency

1. Fast feed design: It belongs to fast feed milling cutter bar. This design is conducive to achieving higher feed speed, effectively improving cutting efficiency, shortening processing time, and improving production efficiency during processing.

2. Internal cooling design: Some tool bars adopt the internal cooling design of the cutter disc. The cutting fluid is transported to the cutting area through the internal cooling channel, which effectively reduces the cutting temperature and reduces tool wear. At the same time, it can also play a role in chip removal, increase cutting feed, and further improve processing efficiency.