About the product

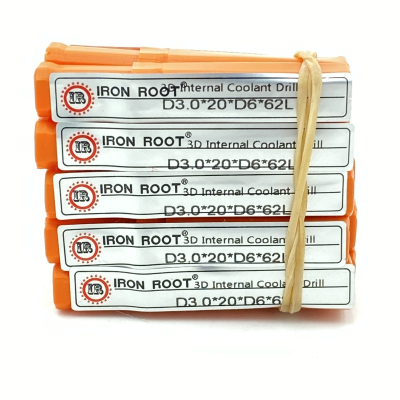

Product sellpoints Compatibility with U Drills:Designed for SP 2D 3D 4D 5D U drills, these inserts ensure a perfect fit for your machining setup.

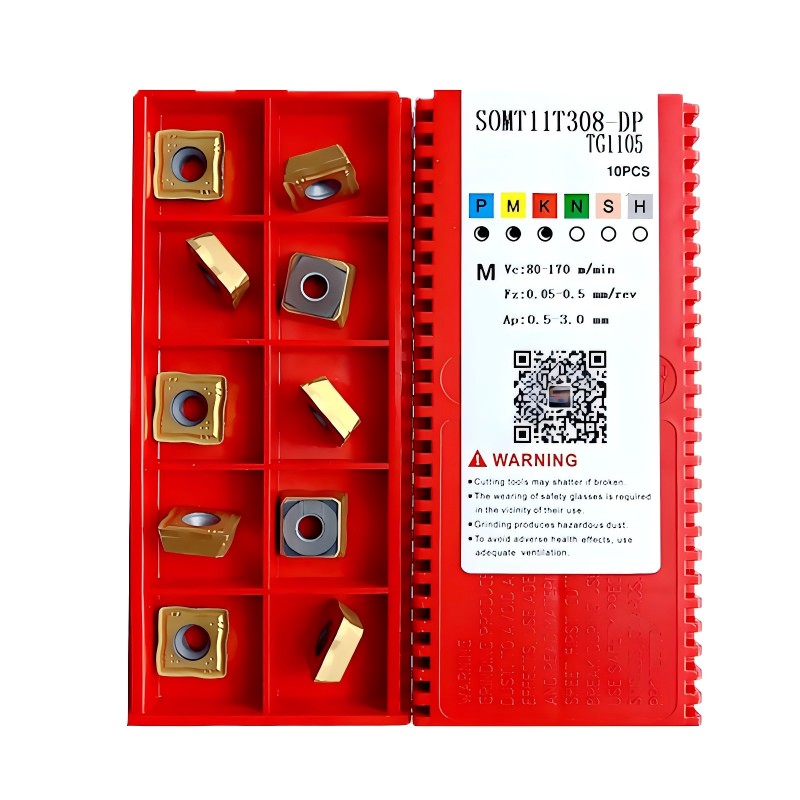

High Hardness:With P15-P25 M10-M25 K10-K25 hardness, the inserts ensure precise and efficient drilling in various materials.

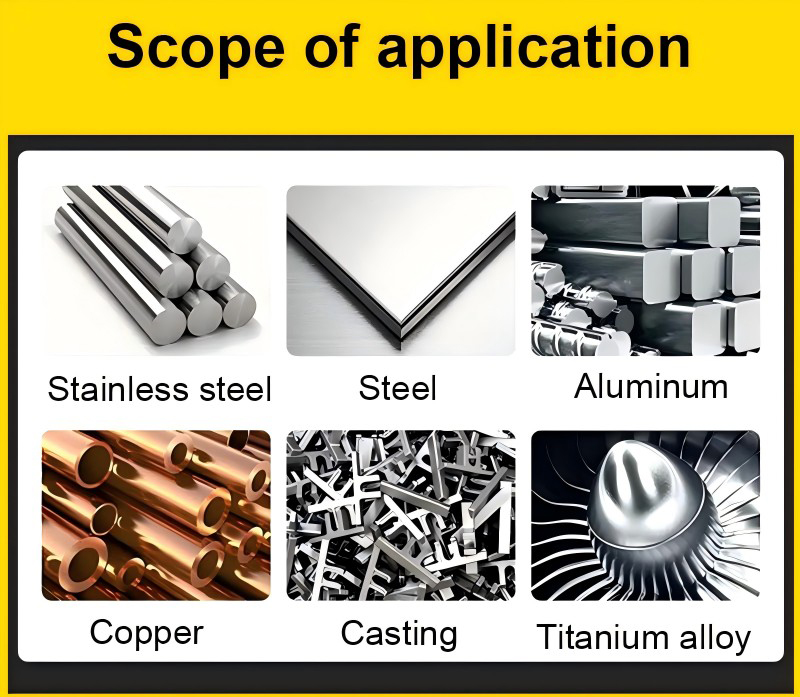

Versatile Processing Materials:Ideal for steel, stainless steel, and P.M.K, these inserts cater to diverse machining needs.

PVD Coating:Featuring a PVD coating, the inserts boast enhanced wear resistance and corrosion protection.

Hss Vs Carbide|Timco Cng|Hard Alloy Material:Crafted from robust hard alloy, these inserts offer exceptional durability and longevity.

![Carbide insert SOMT.jpg Carbide insert SOMT.jpg]()

Base Substrate: Premium hard alloy (cemented carbide) with tungsten carbide (WC) as the main component (92–94% by weight) and 6–8% cobalt (Co) as a binder. The ultra-fine WC grain size (1.0–1.5μm) ensures high density, delivering a hardness of 90–93 HRA—far superior to HSS (high-speed steel) in wear resistance, making it suitable for long-term high-intensity drilling.

PVD Coating: Adopts TiAlN (Titanium Aluminum Nitride) or TiCN (Titanium Carbonitride) PVD coating. The 3–5μm thick coating has a low friction coefficient (≤0.4), resists oxidation at temperatures up to 800°C, and blocks chemical corrosion from coolants. This extends the insert’s wear resistance by 30–50% compared to uncoated inserts.

![Turning blades SOMT.jpg Turning blades SOMT.jpg]()

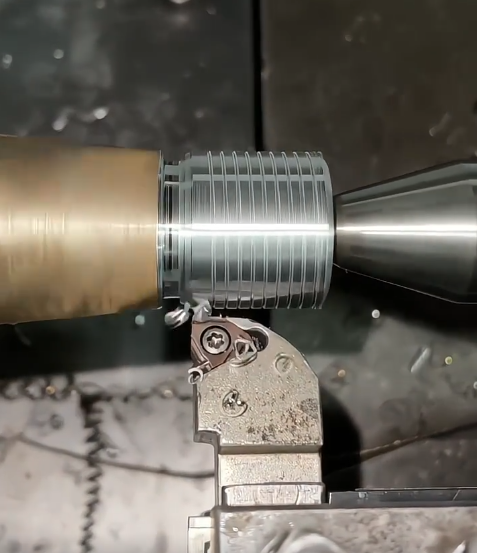

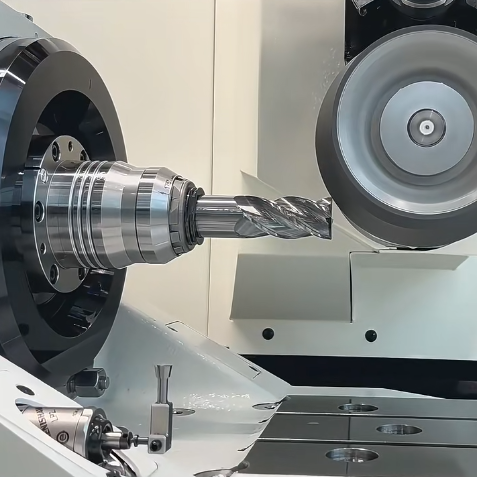

Precise U Drill Compatibility: Custom-engineered for SP series U drills (2D, 3D, 4D, 5D—“D” refers to the ratio of drill depth to diameter). The insert’s seating surface is ground to ±0.002mm tolerance, ensuring a tight fit with U drill holders, minimizing runout (≤0.003mm) and guaranteeing consistent hole accuracy (IT8–IT9 tolerance).

Grade-Specific Hardness for Versatility: Offered in three hardness grades to match different materials:

P15–P25: For carbon steel, alloy steel, and gray cast iron—ideal for general-purpose drilling (e.g., automotive engine block bolt holes).

M10–M25: For stainless steel (304/316) and heat-resistant alloys—prevents work hardening and built-up edge (BUE) during drilling.

K10–K25: For ductile cast iron and non-ferrous metals (aluminum 6061, brass)—balances toughness and wear resistance to avoid chipping.

Efficient Chip Control: Integrated curved chipbreaker grooves are designed to split swarf into short, manageable pieces. This prevents clogging in deep holes (up to 5x diameter) and reduces heat accumulation, protecting the insert edge from premature wear.

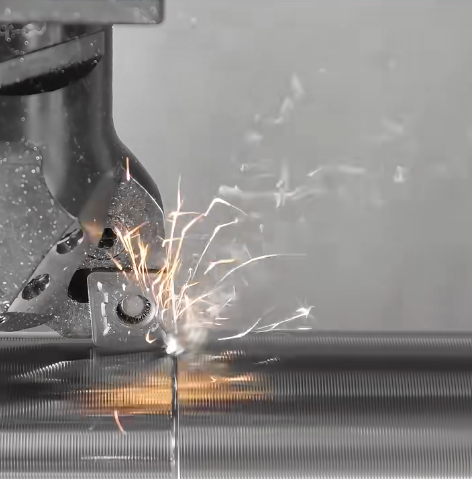

High-Speed Drilling Capability: The rigid alloy and low-friction coating enable 2–3x faster drilling speeds than HSS: 150–300 m/min for steel, 80–150 m/min for stainless steel, and 300–600 m/min for aluminum—cutting cycle time by 40%.

![CNC machine tools SOMT.jpg CNC machine tools SOMT.jpg]()

Target Materials:

Ferrous metals: Carbon steel (Q235, 45#), alloy steel (40Cr), stainless steel (304/316), gray cast iron (HT200), ductile cast iron (QT450).

Non-ferrous metals: Aluminum (6061/7075), brass, copper.

Special materials: P.M.K (precious metal alloys) for precision electronic components.

Industry Uses:

Automotive: Drilling bolt holes in transmission cases, cylinder heads, and chassis parts.

Aerospace: Machining precision holes in aluminum aircraft frames and stainless steel hydraulic fittings.

General engineering: Creating holes in hydraulic manifolds, tooling plates, and industrial gearboxes.

![Indexable blades.gif Indexable blades.gif]()

CNC Machining Centers: Haas VF-series, Fanuc Robodrill, Mazak VTC, DMG MORI DMC (equipped with U drill holders).

CNC Lathes: Mazak Quick Turn, Doosan Puma, Haas ST-series (with drilling spindles or turret-mounted U drill tools).

Specialized U Drill Machines: SP-series dedicated U drill equipment (optimized for high-volume deep-hole drilling).

![U drill insert SOMT.jpg U drill insert SOMT.jpg]()

Service Life:

Steel drilling: 500–1,000 holes (e.g., M10 holes in 45# steel).

Aluminum drilling: 800–1,500 holes (lower material abrasiveness extends life).

Stainless steel drilling: 300–600 holes (high wear due to material toughness).

Maintenance Tips:

Clean the insert and holder with compressed air after use to remove swarf and coolant residue.

Store in a dry, dust-free case to avoid coating corrosion.

Avoid dropping or impact (may chip the hard alloy edge, reducing precision).

About Our Company

Jinan Xinxin Trading Co., Ltd. is a specialized enterprise deeply engaged in the metalworking tool sector, offering a full range of core products including turning tools, milling tools, holemaking tools, carbide cutting tools, and machine tool accessories. It provides one-stop tool procurement support for the machining and manufacturing industry, catering to diverse production needs with comprehensive product coverage.

![Company production machines Company production machines]()

![Company production machines Company production machines]()

![Company production machines Company production machines]()

While supplying standard products, the company further focuses on addressing the personalized demands of the industry by undertaking customization services for various non-standard tools. From material selection and structural design of tools to performance debugging, the entire process is tailored to customers’ specific machining scenarios (such as cutting special materials or forming complex workpieces). It also provides complete supporting tooling solutions, helping customers break through traditional machining bottlenecks and improve production efficiency and precision.

![Company Photo Company Photo]()

After years of in-depth market development, the company has always adhered to the business philosophy of "integrity-based". With stable product quality, professional technical support, and efficient after-sales service, it has won market recognition. Currently, its products have been exported to more than 40 industrialized countries and regions worldwide, including Europe, the Middle East, South America, and Southeast Asia. It has built a solid foundation of trust among domestic and foreign customers, becoming a long-term and reliable tool partner for numerous manufacturing enterprises.

Our Customer Reviews

Our products have been exported to a diverse range of countries, including the United States, the United Kingdom, Spain, Italy, Belgium, France, Germany, and more. They are deeply favored and supported by users across these markets.

We take pride in offering products that stand out for their excellent cost-effectiveness—delivering reliable performance at competitive prices. Every product we provide comes with strict quality assurance, adhering to rigorous manufacturing and inspection standards to ensure consistent durability and functionality. Moreover, we are committed to supplying 100% genuine products, with no compromises on authenticity, so our customers can purchase and use them with complete confidence.

![Good customer feedback Good customer feedback]()

![Good customer feedback Good customer feedback]()

![Good customer feedback Good customer feedback]()

![Good customer feedback Good customer feedback]()

![Good customer feedback Good customer feedback]()

![1754105006169968.png image.png]()

Thank you very much for your attention.

You are warmly welcome to inquire about product prices

we are committed to providing you with our best service.

![Company Customer Service Company Customer Service]()